Negative-pressure-driven annular micro-wedge-shaped bristle bundle suction cup and preparation method thereof

A wedge-shaped, suction-cup technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

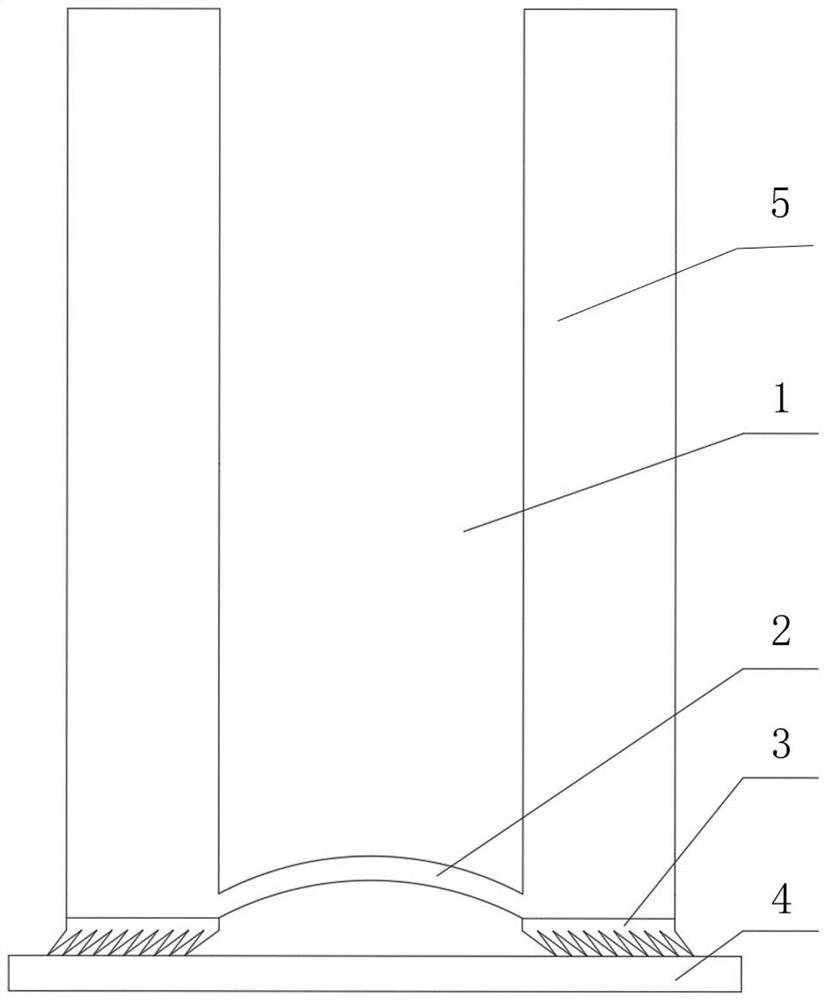

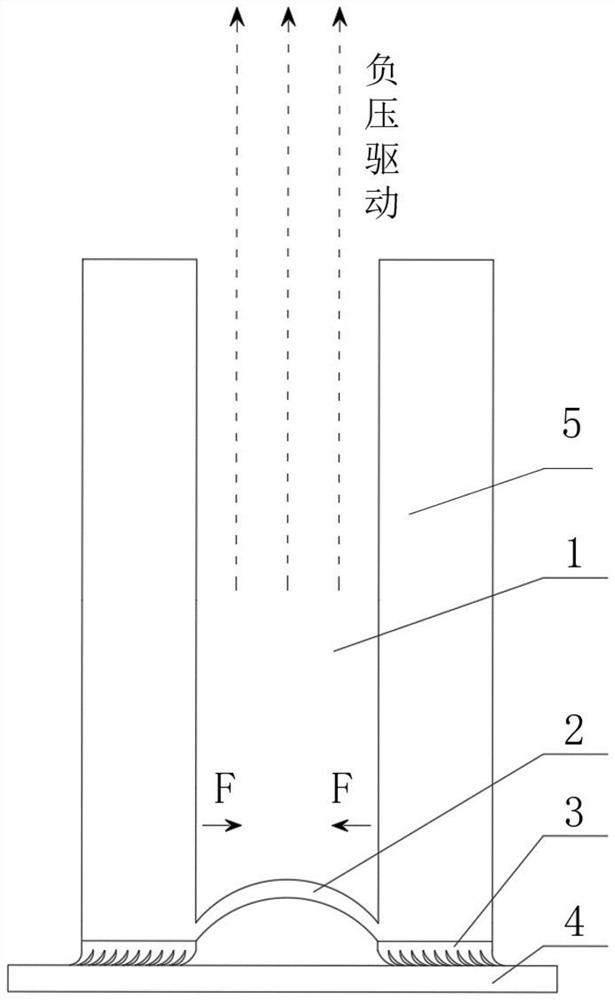

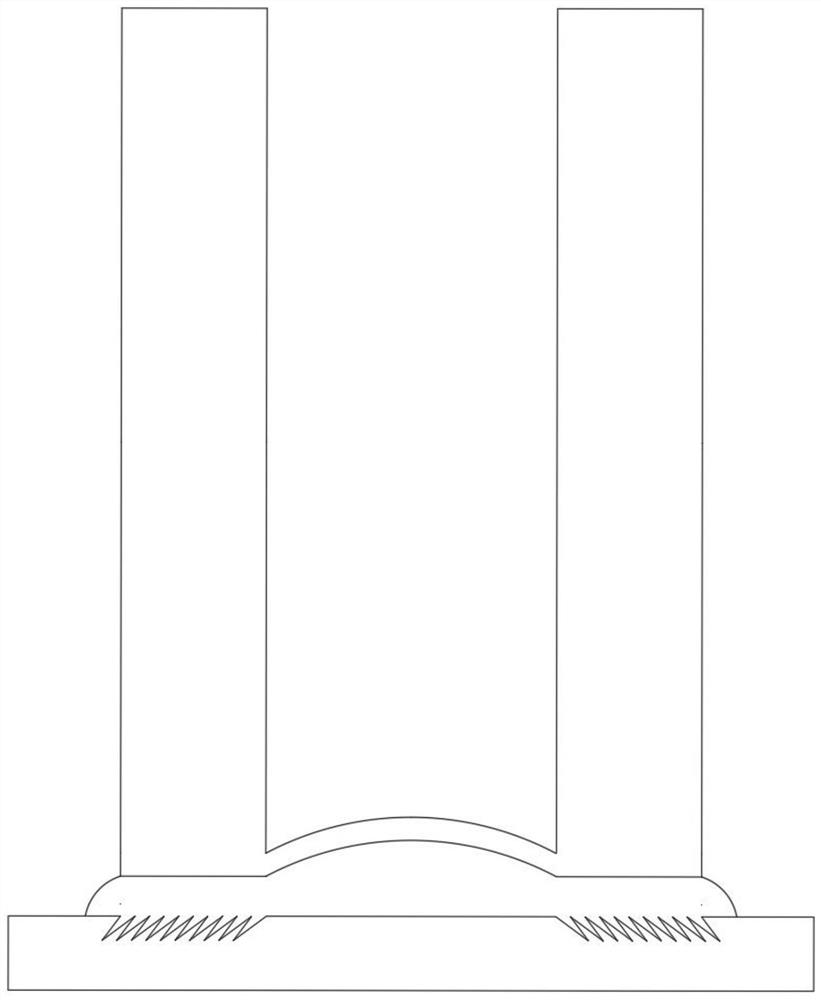

[0037] Such as Figure 1-3 As shown, the present embodiment provides a negative pressure-driven annular micro-wedge-shaped bristle bundle suction cup, including a suction cup body 5, and a negative pressure chamber 1 axially penetrated in the middle of the suction cup body 5, specifically, the suction cup body 5 is cylindrical , the bottom surface of the suction cup body 5 is a flat torus, and the negative pressure chamber 1 is a cylindrical cavity; the top of the negative pressure chamber 1 is connected to the vacuum air circuit through a pneumatic joint, and the cylindrical negative pressure chamber 1 can be A uniform contraction deformation along the center is generated, and a uniform centripetal load is provided for the annular micro-wedge-shaped bristle bundle 3 . The bottom of the negative pressure chamber 1 is provided with a deformation layer 2, and the bottom surface of the suction cup body 5 is provided with an annular micro-wedge-shaped bristle bundle 3, and the def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com