Novel siphon type water decanter, SBR and control method of novel siphon type water decanter

A siphon type decanter and reactor technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can not work normally, the flow of the water inlet is uneven, etc., to achieve the effect of convenient transportation and on-site installation, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

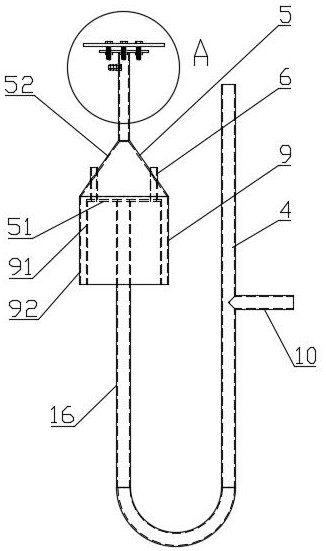

[0040] Such as Figure 1~4 As shown, this embodiment provides a novel siphon decanter, including an annular drainage channel 9 , a conical confluence chamber 5 , an air valve 3 , a U-shaped pipe 16 , and a drain pipe 10 .

[0041] Specifically, the annular drainage channel 9 is vertically arranged, and the annular drainage channel 9 includes an inner cylinder 91 and an outer cylinder 92. The inner cylinder 91 and the outer cylinder 92 form an annular drainage space, which has equal resistance drainage and makes the annular drainage channel 9 Evenly enter water along the circumference to prevent the effect of stirring and sedimentation.

[0042] More specifically, a plurality of connecting strips 93 are arranged between the inner cylinder 91 and the outer cylinder 92, and the connecting strips 93 are used to control the concentricity of the inner cylinder 91 and the outer cylinder 92, and can also play a supporting role to improve the inner cylinder 91. And the stability of ou...

Embodiment 2

[0050] Such as Figure 5 As shown, a kind of novel SBR reactor provided for the present embodiment, comprises central controller, SBR reaction tank, and the novel siphon type decanter described in embodiment 1 that is positioned at SBR reaction tank, liquid level sensor 15, exposure The gas device 17 and the liquid level sensor 15 are used to collect the information of the water level in the SBR reaction tank, and transmit the information to the central controller, and the central controller is used to receive the information of the liquid level sensor 15, and compare the information of the above water level with the preset Value comparison, when the water level reaches the corresponding preset value, the central controller controls the opening and closing of the air valve 3.

[0051] Preferably, the liquid level sensor 15 is set as a drop-in liquid level gauge.

Embodiment 3

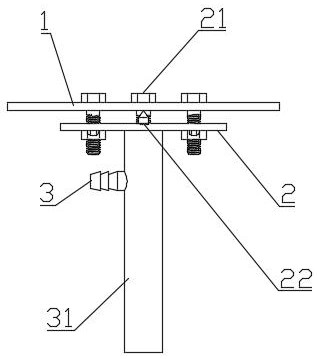

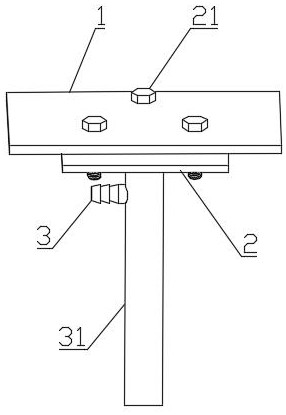

[0053] Such as Figure 6 As shown, the control method of a new type of SBR reactor provided by this embodiment adopts the new type of SBR reactor described in Example 2. When installing, first use the top cone 22 to resist the decanter mounting plate 1, and adjust the Three bolts 21 adjust the water inlet of the annular gap drainage channel 9 to the level, and the control methods include:

[0054] S1. In the idle stage, before the sewage starts to flow in, it is the waiting state after the drainage in the previous cycle is completed, that is, the lowest water level line 14. At this time, the air valve 3 is closed, and the first time it is used, it passes through the overflow pipe 4 to The U-shaped pipe 16 is filled with water until excess water flows out from the drain pipe 10;

[0055] S2. In the water inlet stage, the air valve 3 is closed, and the sewage to be treated is injected into the SBR reactor through the water inlet pipe 11. The liquid level of the sewage is from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com