Low-temperature superplastic low-alloy-content magnesium alloy and preparation method thereof

A magnesium alloy and low alloy technology, applied in the field of magnesium alloy, can solve the problems of low strength and ductility, and achieve the effect of promoting dynamic precipitation, simple process and shortening process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

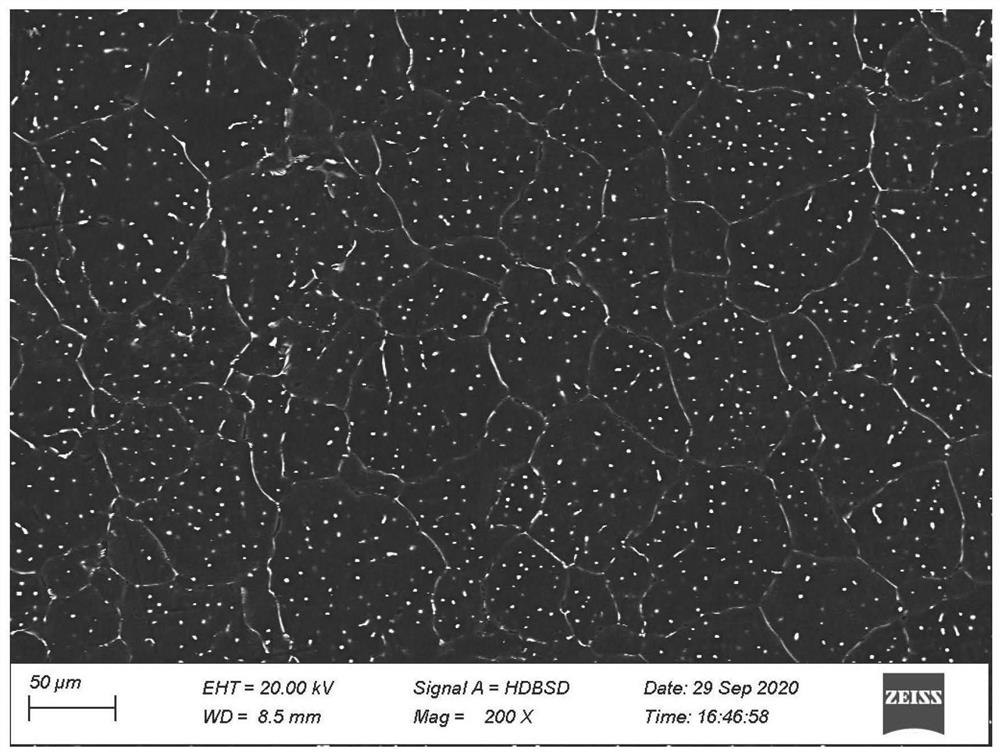

[0033] A low-temperature superplastic low alloy content Mg-1wt.%Al-1wt.%Zn-0.3wt.%Ca-0.2wt.%Sn (hereinafter referred to as: Mg-1Al-1Zn-0.3Ca-0.2Sn) alloy, it The preparation method comprises the following steps:

[0034] (1) Preparation of sub-rapid solidification cast alloy slab

[0035] Commercially pure Al, commercially pure Zn, commercially pure Sn, Mg-25wt.% Ca master alloy, commercially pure Mg ingots and unavoidable impurities were melted at 680°C, stirred for 1 min under the protection of argon, and then cleaned. Slag treatment, obtain Mg-1Al-1Zn-0.3Ca-0.2Sn alloy melt after holding at 650°C for 10-30min, and then cast the above Mg-1Al-1Zn-0.3Ca-0.2Sn alloy melt into a water-cooled copper mold During cooling and solidification at a speed of 203K / s for 4 minutes, a Mg-1Al-1Zn-0.3Ca-0.2Sn alloy slab was obtained, and the thickness of the slab was 6mm;

[0036] (2) Low temperature controlled rolling with large reduction in single pass

[0037] Preheat the Mg-1Al-1Zn-0....

Embodiment 2

[0042] A high-strength plastic low alloy content Mg-1wt.%Al-1wt.%Zn-0.3wt.%Ca (hereinafter referred to as: Mg-1Al-1Zn-0.3Ca) alloy, its preparation method comprises the following steps:

[0043] (1) Preparation of sub-rapid solidification cast alloy

[0044]Commercially pure Al, commercially pure Zn, commercially pure Sn, Mg-20wt.% Ca master alloy, commercially pure Mg ingots and unavoidable impurities were melted at 670°C and stirred for 2 minutes under the protection of argon. Slag removal treatment, after holding at 650°C for 10-30min to obtain Mg-1Al-1Zn-0.3Ca alloy melt, then cast the alloy melt into a water-cooled copper mold, cool and solidify at a speed of 275K / s for 2min, and obtain Mg - 1Al-1Zn-0.3Ca alloy slab, the thickness of which is 3mm;

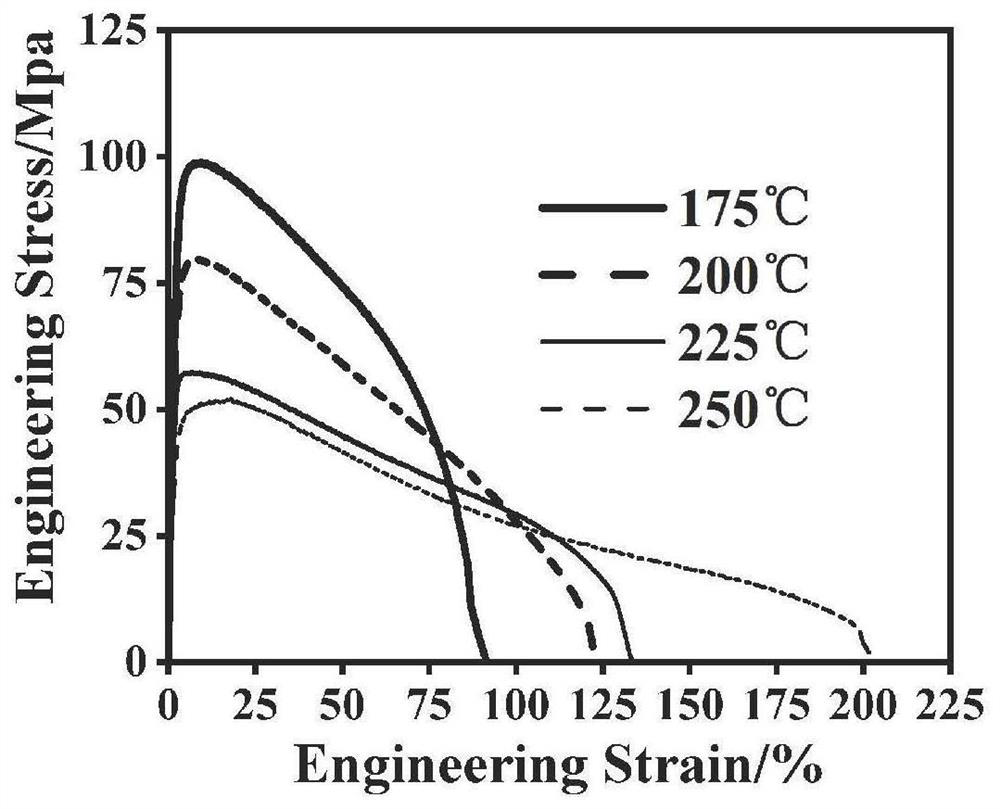

[0045] (2) Low temperature controlled rolling with large reduction in single pass

[0046] Preheat the Mg-1Al-1Zn-0.3Ca alloy slab obtained in step (1) at 300° C. for 15 minutes, and perform single-pass rolling to obtain a t...

Embodiment 3

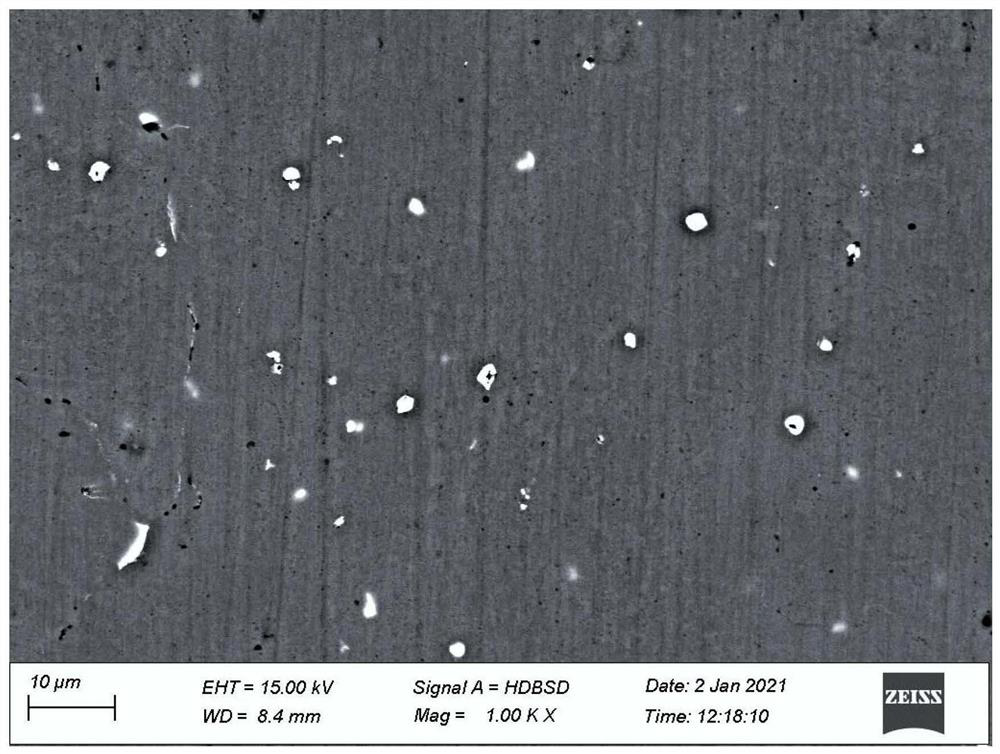

[0049] A low-temperature superplastic low alloy content Mg-1wt.%Al-1wt.%Zn-0.2wt.%Sn-0.1wt.%Ca (hereinafter referred to as: Mg-1Al-1Zn-0.2Sn-0.1Ca) magnesium alloy, Its preparation method comprises the following steps:

[0050] (1) Preparation of sub-rapid solidification cast alloy

[0051] Commercially pure Al, commercially pure Zn, commercially pure Sn, Mg-30wt.% Ca master alloy, commercially pure Mg ingots and unavoidable impurities were melted at 685°C and stirred for 3 minutes under argon protection. Slag removal treatment, after holding at 660°C for 10-30min, the Mg-1Al-1Zn-0.2Sn-0.1Ca alloy melt is obtained, and then the alloy melt is cast into a water-cooled copper mold, and cooled and solidified at a speed of 225K / s for 3min , to obtain Mg-1Al-1Zn-0.2Sn-0.1Ca alloy slab, the thickness of the alloy slab is 5mm;

[0052] (2) Low temperature controlled rolling with large reduction in single pass

[0053] Preheat the Mg-1Al-1Zn-0.2Sn-0.1Ca alloy slab obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com