Grouting sleeve, fabricated bridge pier connected by grouting sleeve and construction method of fabricated bridge pier

A grouting sleeve and assembly technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of grouting sleeve connection strength reduction, connection strength reduction, construction errors, etc., to eliminate bonding failure and enhance Adhesive force, convenient and fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

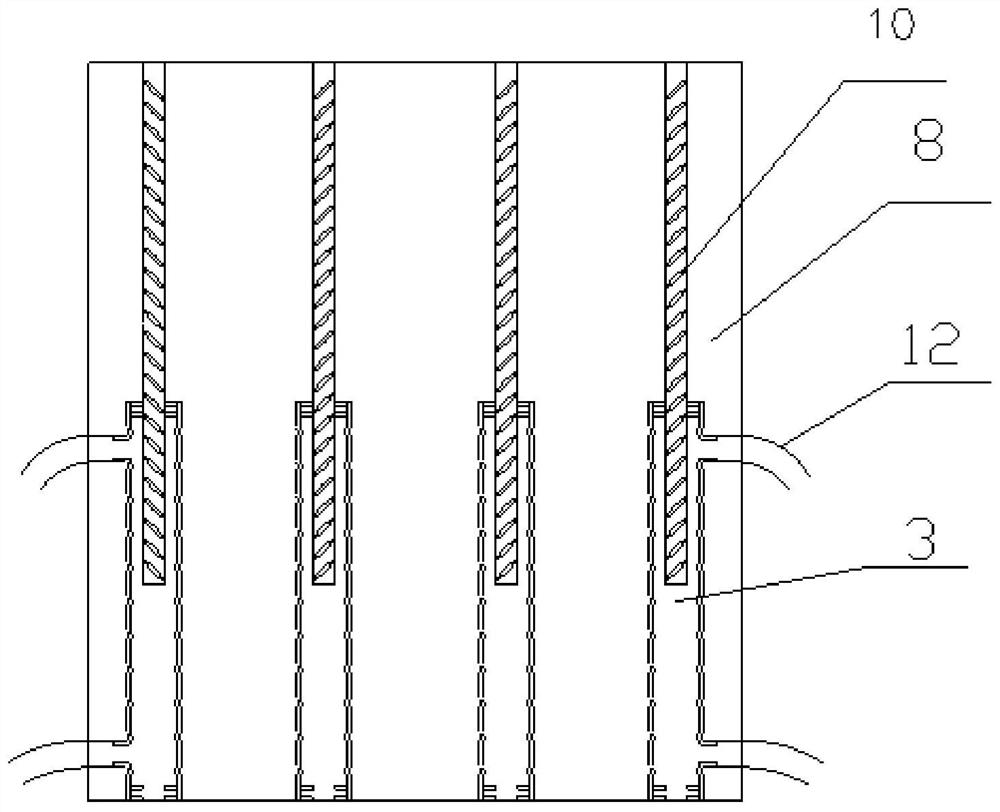

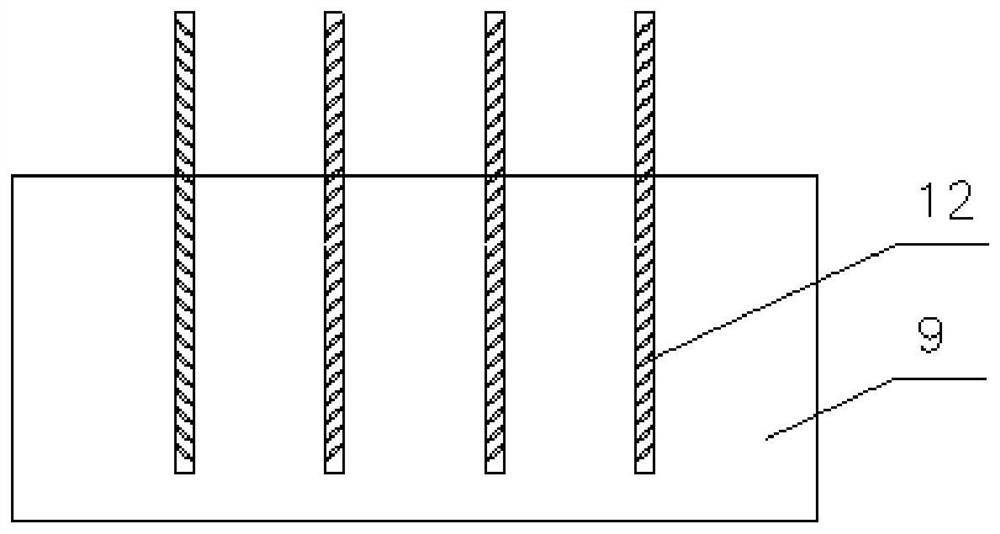

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

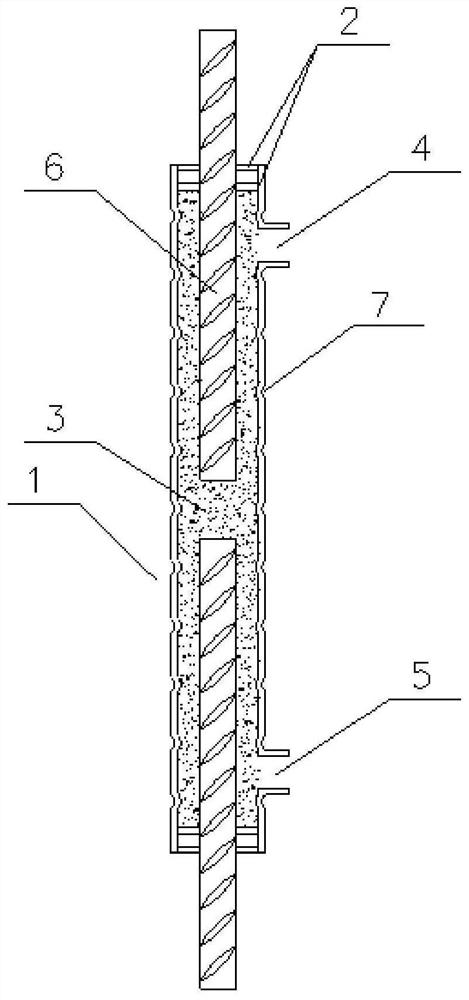

[0035] Such as figure 1 As shown, a grouting sleeve includes a cylinder body 1 with a grouting cavity inside, gaskets 2 arranged at both ends of the cylinder body 1 and a grouting material layer 3 filled in the grouting cavity of the cylinder body 1 . The gasket 2 is a metal gasket 2, and the metal gasket 2 is welded at the end of the grouting sleeve, which can effectively prevent the axial sliding of the grouting material in the sleeve and eliminate the bonding caused by the excessive relative slip between the grouting material and the inner wall of the sleeve Failure phenomenon, enhance the connection strength of the grouting sleeve. The grouting material is concrete mortar made of fine aggregate. The outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com