Shield attitude-adjustable laser target continuous measurement system

A technology of shield attitude and laser target, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of large measurement error, inability to achieve continuous measurement, and easy damage to the front floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

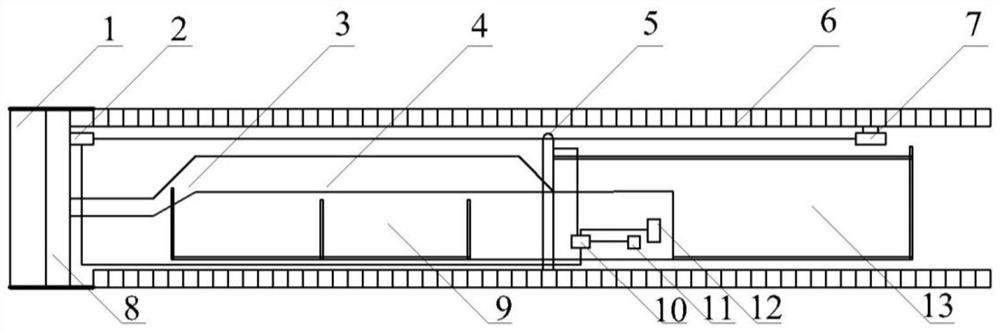

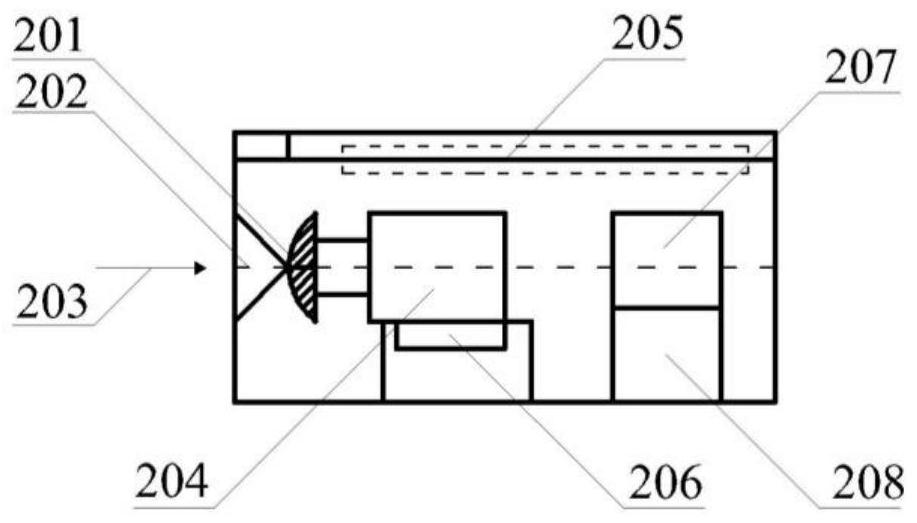

[0042] A shield attitude adjustment laser target continuous measurement system, please refer to Figure 1-Figure 3 , including a PLC controller 11, a navigation computer system 10, a moving laser target 2 set on the shield 8 in the shield machine, a rearview prism 7 set on the tunnel segment 6, and a gyroscope set in the supporting system 9 behind the shield machine Total station 5, alarm device 12; Wherein, mobile laser target 2 comprises laser receiving device 202, signal processing device 205, the laser gyroscope 207 that is connected with signal processing device 205 and quartz pendulum accelerometer 208, is arranged on laser receiving device Convex lens 201 between 202 and signal processing device 205; Signal processing device 205 comprises imaging mechanism 204, inclinometer 206; Mobile laser target 2 is connected with navigation computer system 10 by data line, and gyro total station 5 is by data line and navigation computer system 10 connection;

[0043] The gyro tota...

Embodiment 2

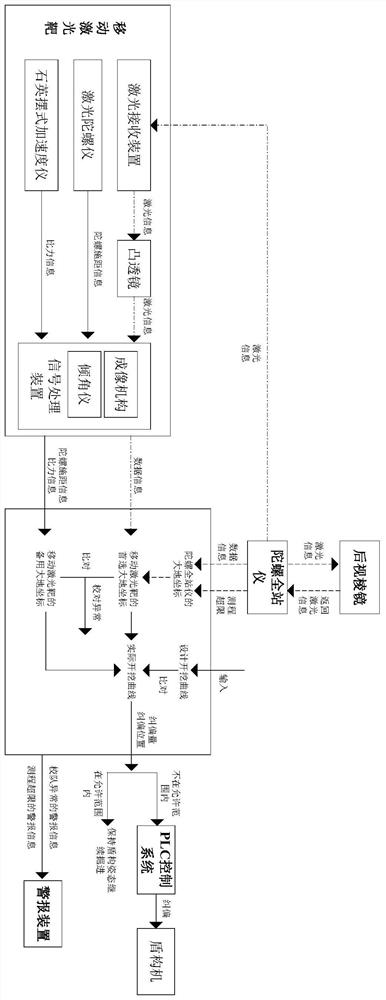

[0053] The working process of the shield posture adjustment laser target continuous measurement system of the present invention is as follows:

[0054] (1) Please refer to figure 1 , during the shield excavation process, the backsight prism 7 is fixed on the tunnel segment 6, and at the beginning of the measurement, the geodetic coordinates of the backsight prism 7 (X 1 ,Y 1 ,Z 1 );

[0055] (2) See image 3 , the laser information (laser beam) sent by the gyro total station 5 shoots to the rear-view prism 7, and after the laser information returns through the rear-view prism 7, the gyro total station 5 converts the returned laser signal into a digital signal and transmits it to the navigation computer system 10, the navigation computer system 10 calculates the geodetic coordinate (X 2 ,Y 2 ,Z 2 );

[0056] (3) Please refer to Figure 1-Figure 3 , the gyro total station 5 rotates 180 ° to search for the moving laser target 2, and sends the laser information (laser bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com