Rodless cylinder

A rodless cylinder, cylinder block technology, applied in bearings, linear motion bearings, fluid pressure actuating devices, etc., can solve the problem of low running accuracy of rodless cylinders, small load capacity of rodless cylinders, and easy sliding of the slider from side to side. and other problems, to achieve the effect of large load capacity, long service life and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The present invention will be further described below in conjunction with the accompanying drawings and specific examples to better understand the invention and can be implemented, but the embodiments are not limited thereto.

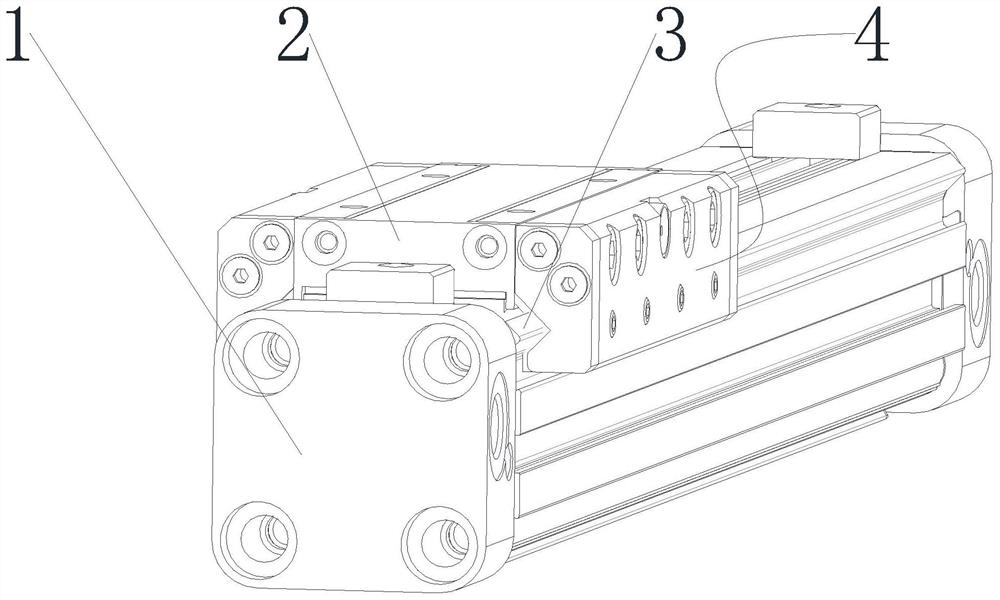

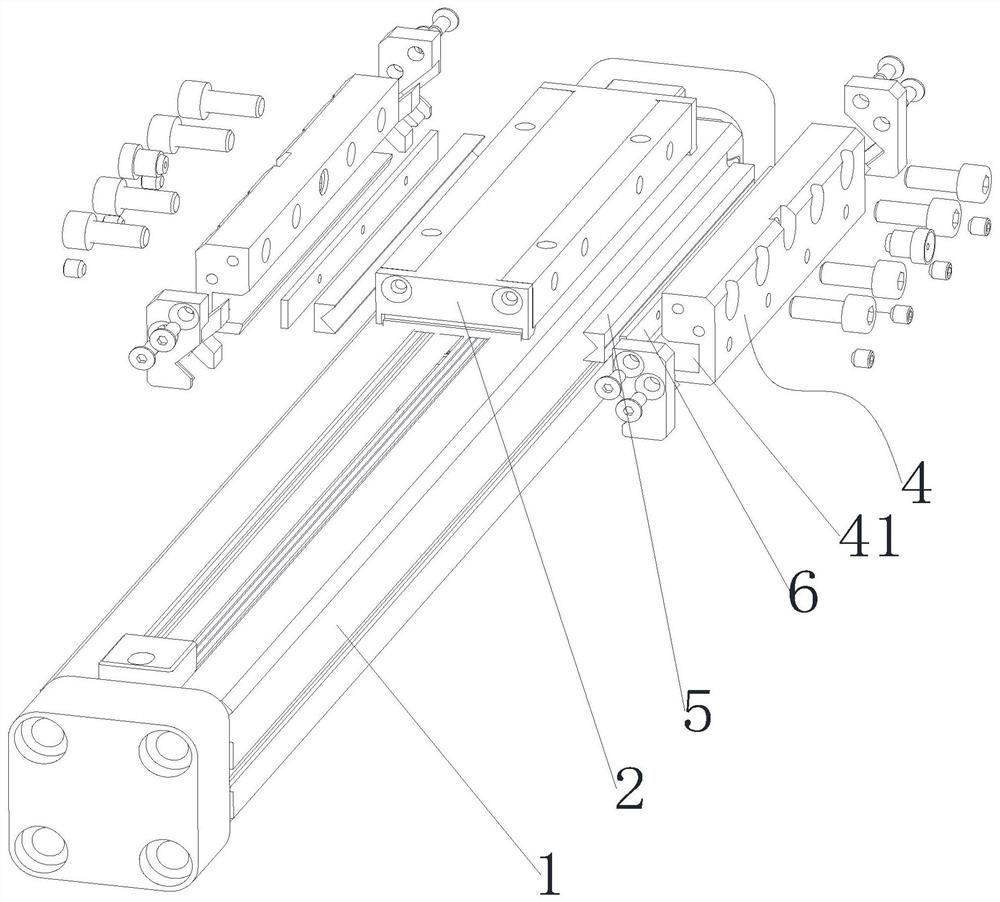

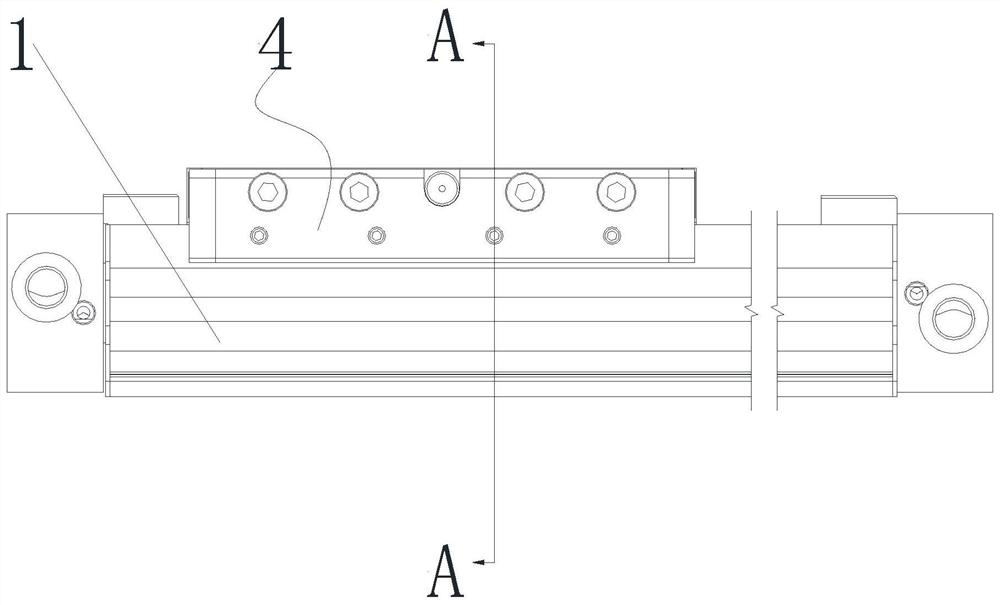

[0025]Referfigure 1 ,figure 2 ,image 3 withFigure 4As shown, a non-bar cylinder comprising a cylinder 1 and a movable slider 2 on the cylinder 1 and can move axially along the cylinder 1, the top surface of the slider 2 is horizontally, the side of the cylinder 1 A pair of symmetrical support ridges 3 on both sides of the slider 2 are provided on the top wall, in the present embodiment, the support ridge 3 is V-shaped. The guiding mounting blocks 4 are detachably connected to both sides of the slider 2, in the present embodiment, the slider 2 is threaded with the guide mounting block 4. The top surface of the mounting block 4 is flush with the top surface of the slider 2, and it is provided with a guide groove 41 that can accommodate the support ridge 3 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com