Separating and drying device for preparing basic cupric carbonate from copper-containing etching waste liquid

A drying device and copper etching technology, applied in the direction of drying gas arrangement, non-progressive dryer, dryer combination, etc., can solve the problems of unsatisfactory drying effect and high drying cost of basic copper carbonate, so as to save drying cost, Efficient drying and the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

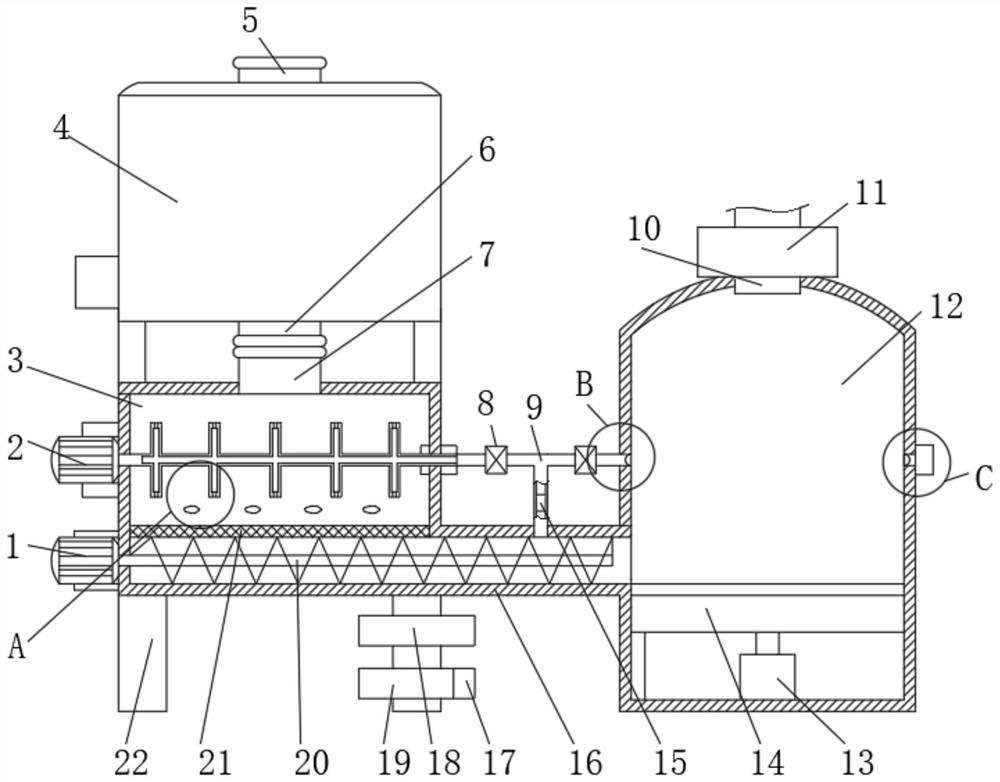

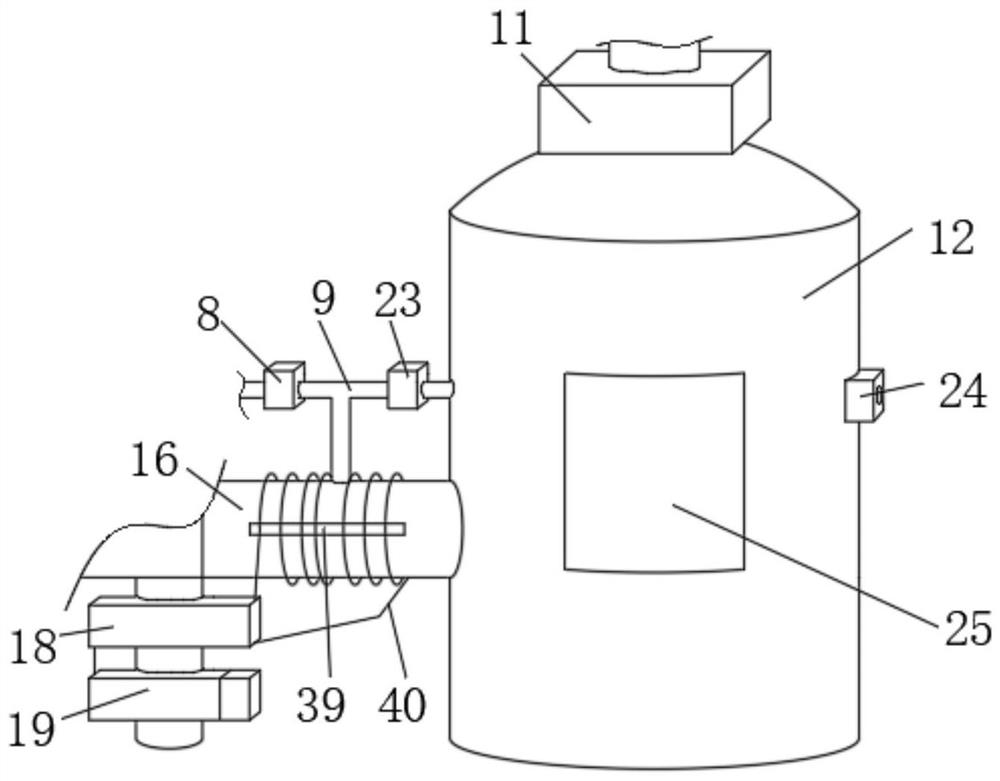

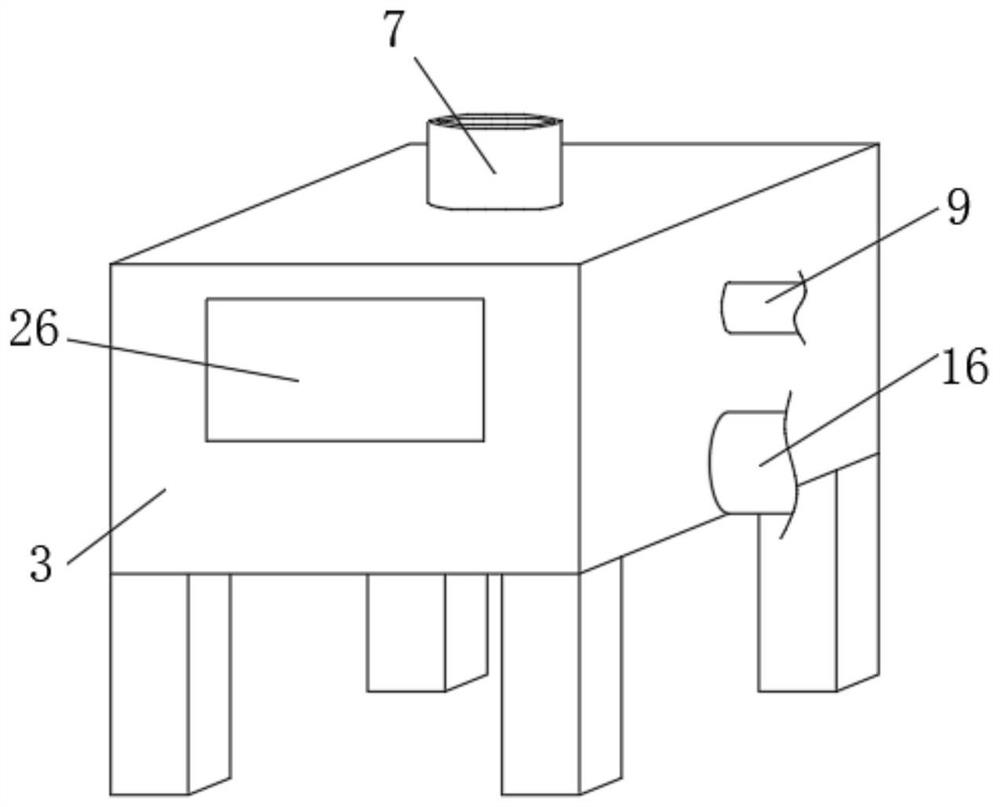

[0029] Such as Figure 1-7As shown, the embodiment of the present invention provides a separation and drying device for preparing basic copper carbonate from copper-containing etching waste liquid, comprising a drying box 3, and the middle and upper part of the drying box 3 is rotatably connected with a stirring rod 36, and one end of the stirring rod 36 runs through One side wall of the drying box 3 is fixedly connected to the driving end of the second motor 2 and the second motor 2 is fixedly connected to the outer wall of the drying box 3, and the other end of the stirring rod 36 runs through the other side of the drying box 3 The side wall is also rotatably connected to the upper side of the T-shaped pipe 9, the inner middle part of the stirring rod 36 is provided with an air channel 37, and the ends of the air channel 37 are all provided with filter cotton, the second valve 23 is closed and the first valve 8 is opened. The hot air formed by drying inside the feed pipe 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com