Double-ring micromechanical gyroscope structure with wide range and high precision

A mechanical gyro and high-precision technology, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, measuring device, etc., can solve the problem that the micro-mechanical vibrating gyro cannot have both large range and high precision, and achieve ingenious design , reasonable structure and flexible working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

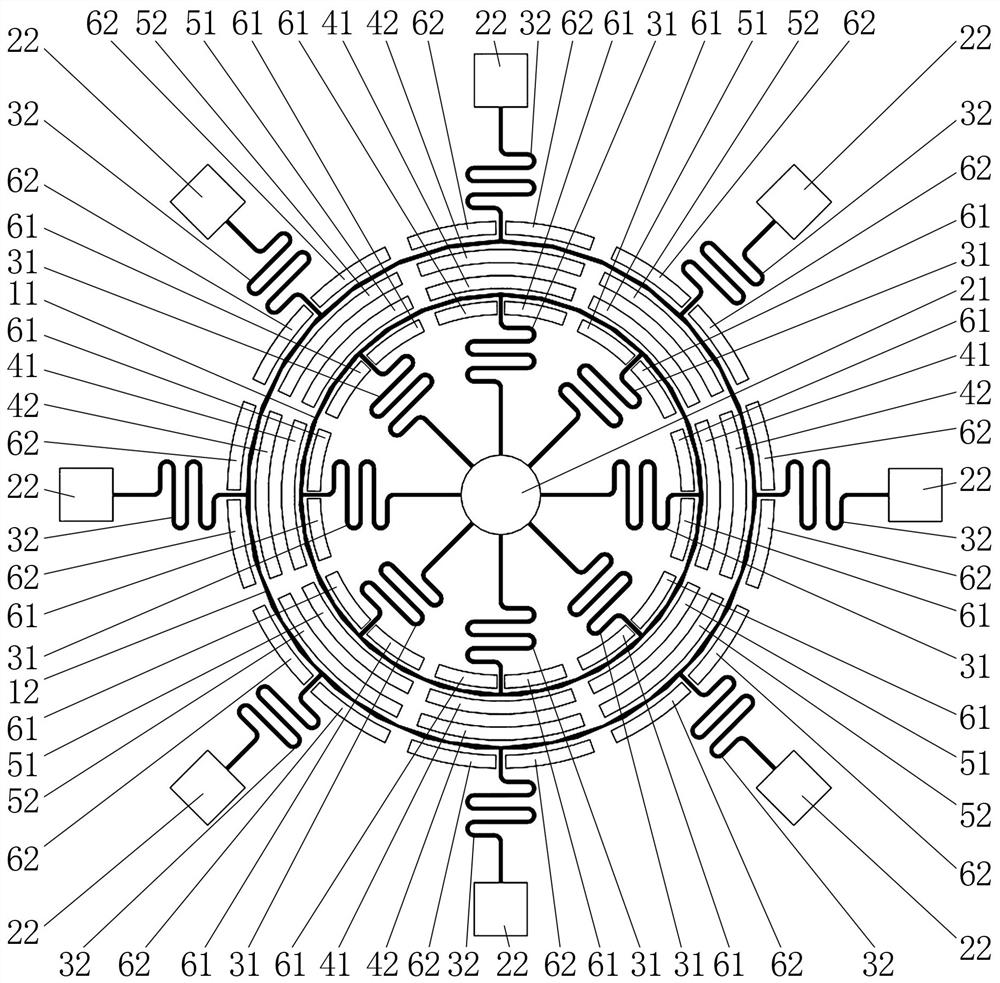

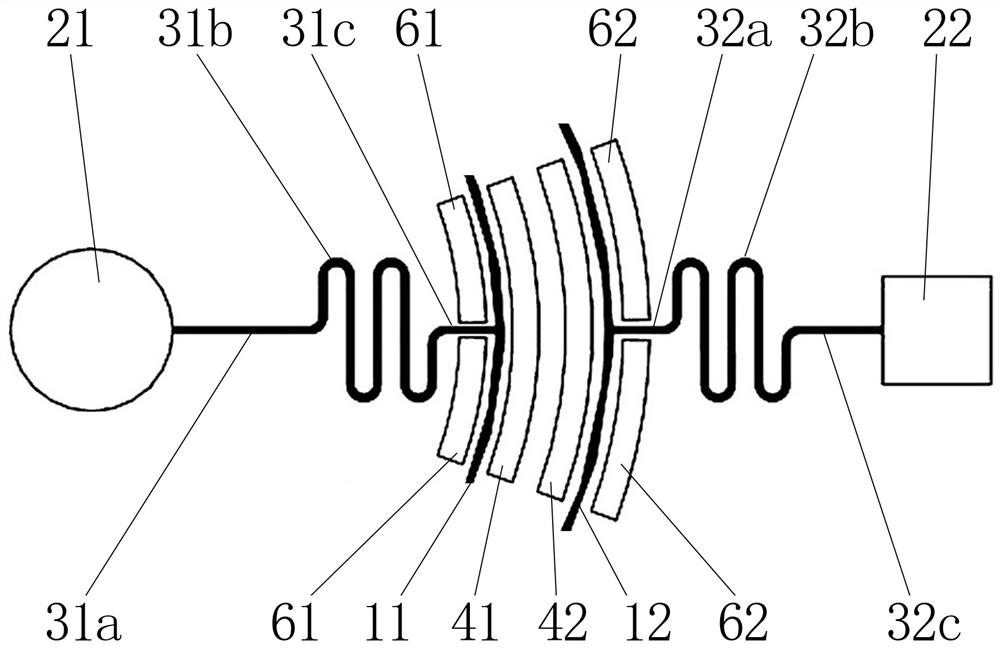

[0030] A double-ring micromechanical gyro structure with both large range and high precision, including a glass substrate, a resonator part, and an electrode part;

[0031] The harmonic oscillator part includes an annular inner layer resonant mass 11, an annular outer layer resonant mass 12, a cylindrical central anchor point 21, eight block-shaped peripheral anchor points 22, eight spoke-shaped inner elastic support suspension beams 31, Eight spoke-shaped outer elastic support suspension beams 32;

[0032] The electrode part includes four arc-shaped inner layer drive mode displacement measurement electrodes 41, four arc-shaped outer layer drive mode displacement measurement electrodes 42, four arc-shaped inner layer detection mode displacement measurement electrodes 51, four arc-shaped Shaped outer layer detection modal displacement measurement electrodes 52, eight pairs of arc-shaped inner layer control electrodes 61, eight pairs of arc-shaped outer layer control electrodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com