Method and device for rapidly measuring gas content of coal seam

A technology for rapid measurement of coal seam gas, applied in the direction of analyzing materials, instruments, etc., can solve the problems of cumbersome steps and high time cost, and achieve the effects of simple operation, simple method and shortening of the measurement period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

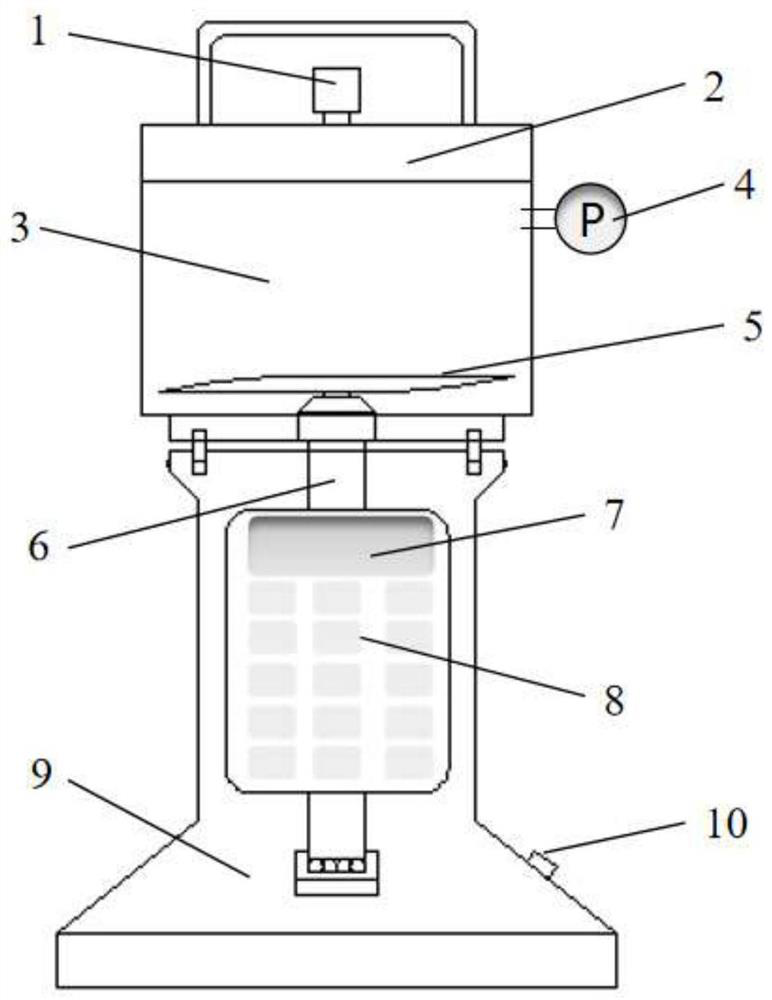

[0057] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

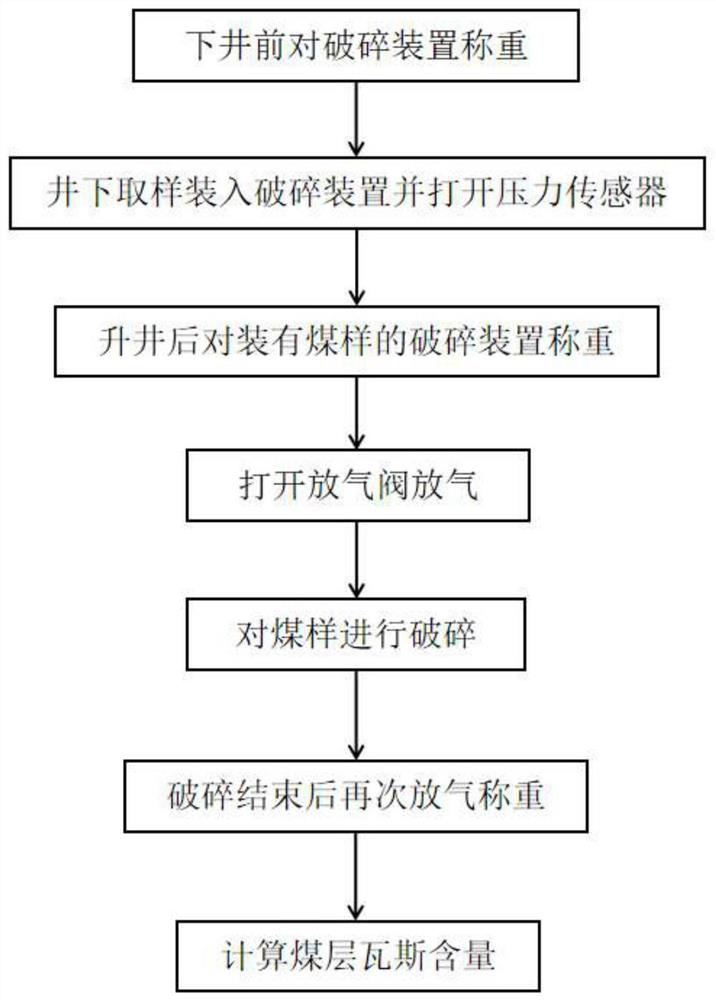

[0058] A kind of method of quickly measuring coal seam gas content of the present invention, concrete steps are as follows:

[0059] a. Before going into the well, clean and weigh the crushing device without coal samples, record it as the weight m 1 , after going down the well, take coal samples downhole and put them into the crushing chamber 3 of the crushing device, turn on the pressure sensor 4 at the same time, drill at the test site selected in the downhole and lower the coring casing to take coal samples, and select coal with relatively large particle size Put 300-500g sample into the crushing device and seal it. At the same time, use a special stopwatch to start timing when the coal is seen, and record the temperature and atmospheric pressure with an aneroid barometer, and record the time t from when the coal is drilled to see the coal sample into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com