Super Junction Power Devices

A power device, n-type technology, applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve the problem of long reverse recovery time, achieve fast reverse recovery speed, small chip size, and improve reverse recovery speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be fully described below through specific implementation manners with reference to the drawings in the embodiments of the present invention. At the same time, in order to clearly illustrate the specific implementation methods of the present invention, the schematic diagrams listed in the drawings of the specification enlarge the size of the layers and regions described in the present invention, and the listed figures do not represent the actual size. The embodiments listed in the specification should not be limited to the specific shapes of the regions shown in the drawings of the specification, but include the resulting shapes such as deviations caused by manufacturing and the like.

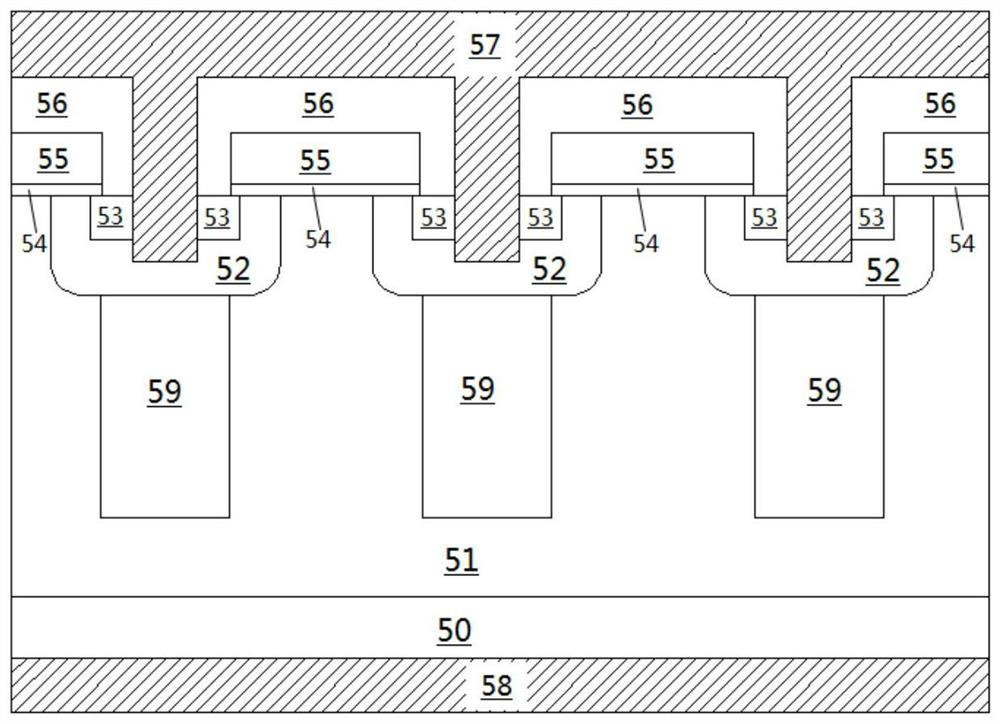

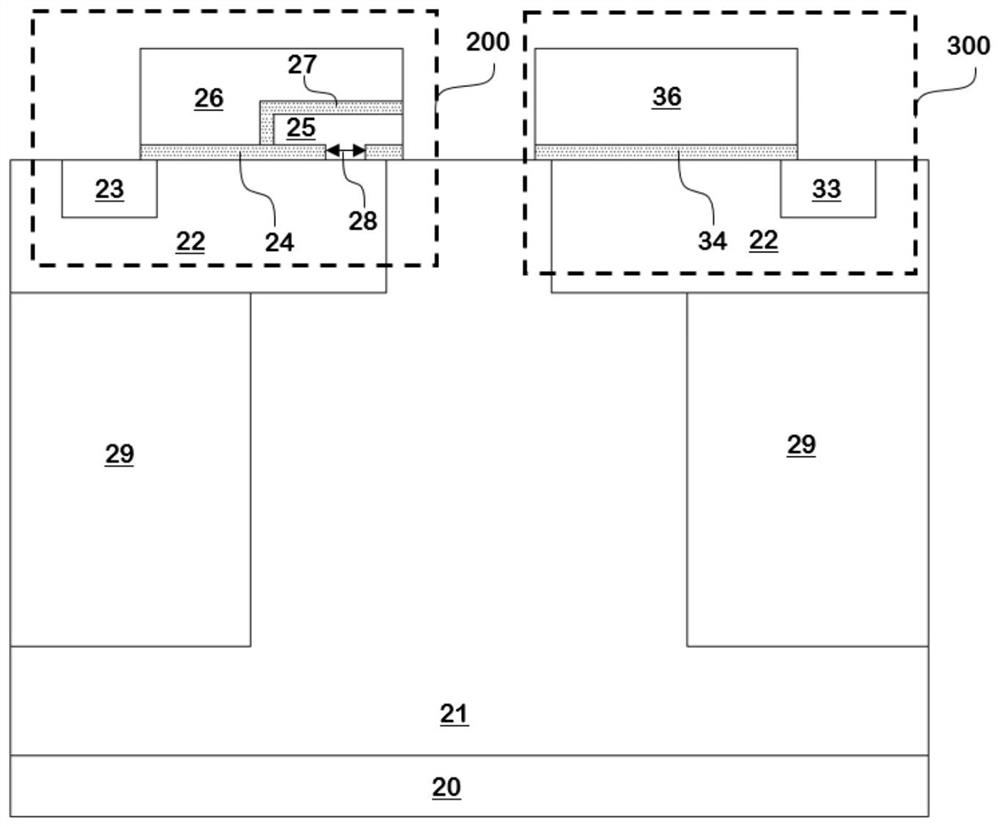

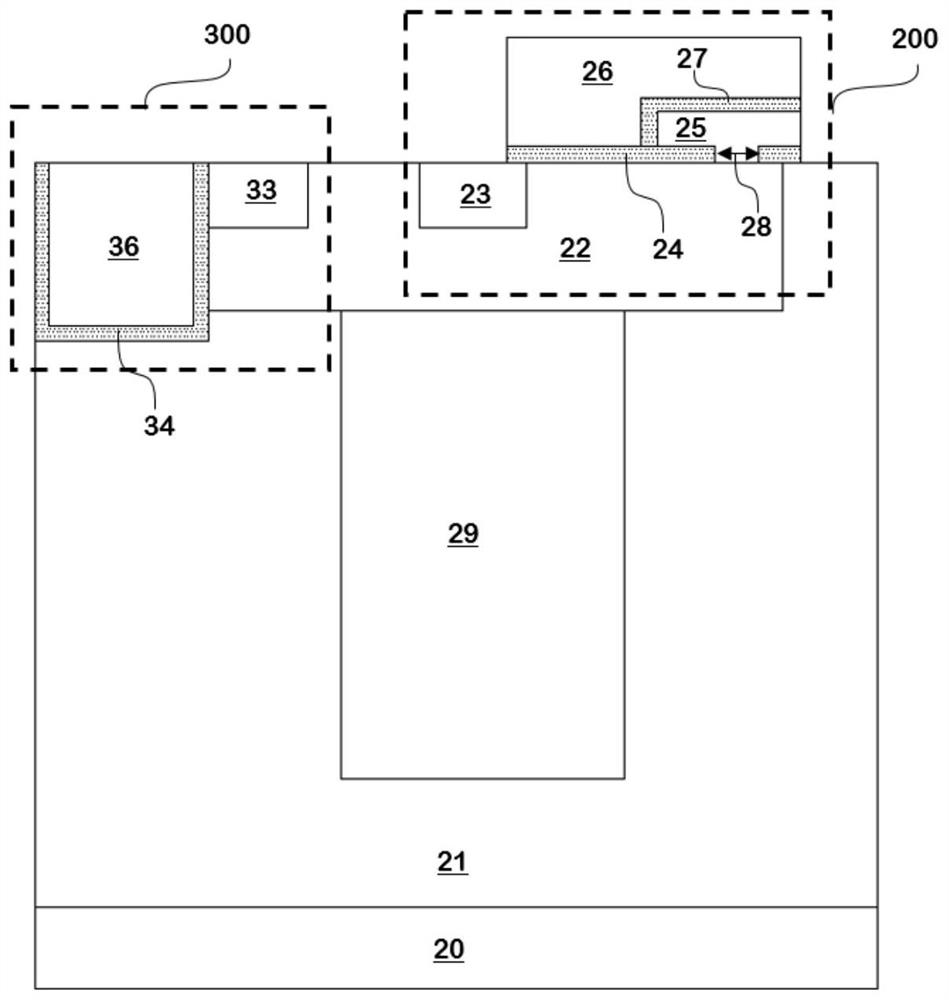

[0021] figure 2 It is a schematic cross-sectional structure diagram of the first embodiment of a super junction power device provided by the present invention, such as figure 2 As shown, a super junction power device provided by an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com