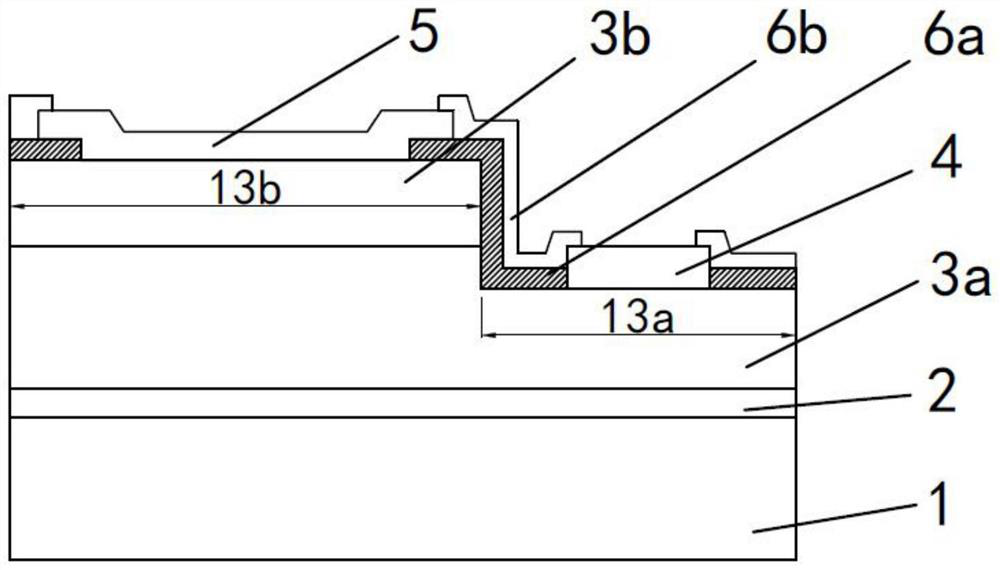

Sub-vertical-structure gallium nitride Schottky barrier diode and manufacturing method thereof

A technology with vertical structure and Schottky potential, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as large reverse leakage current, low reverse withstand voltage, and insufficient stability, and achieve reverse Effects of small leakage current, high reverse recovery speed, and moderate electric field intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A gallium nitride Schottky barrier diode with sapphire as the substrate 1 disclosed in this embodiment uses C-plane sapphire with a thickness of 430 μm and an inclination of 0.15 degrees to the m-plane as the substrate. The specific manufacturing method is as follows:

[0057] Z1: The substrate 1 with a clean surface is placed on the tray of the MOCVD reaction furnace, and the surface is re-cleaned at a high temperature (1020°C) in a reducing atmosphere, and then the temperature is lowered to 550°C. gallium (TMGa) and ammonia (NH 3 ) as the raw material, the GaN material is grown at low temperature to form the GaN buffer layer 2, and then the temperature is gradually raised to crystallize the atomic sequence of the low-temperature GaN material. Wherein the thickness of the GaN buffer layer 2 is controlled at 10 nm.

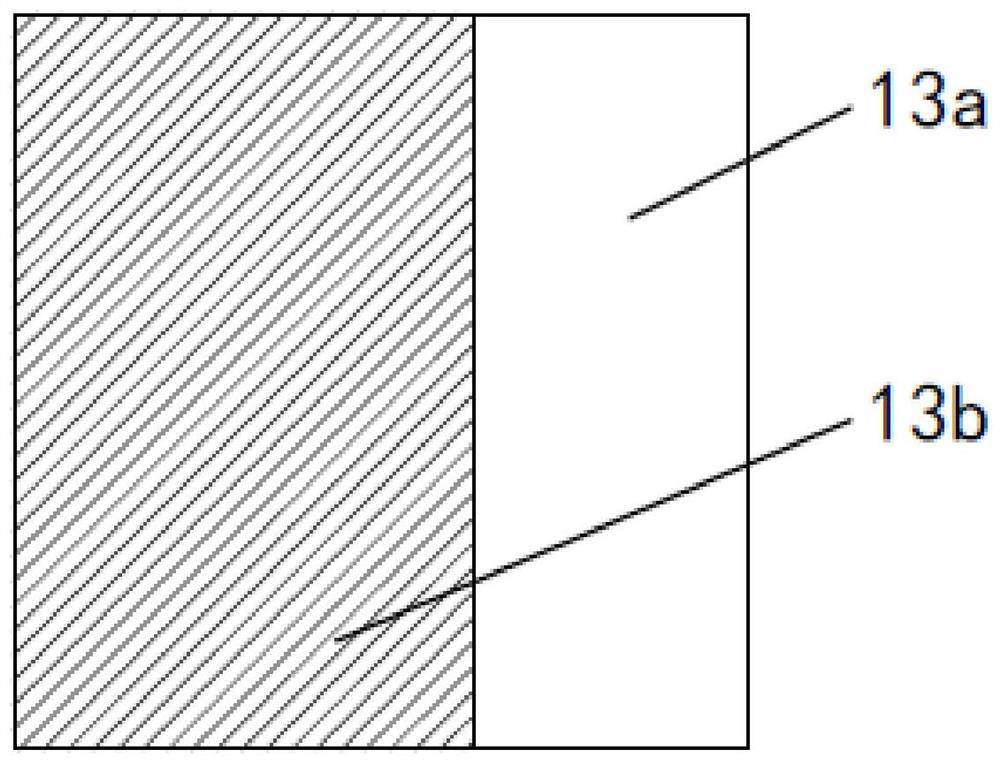

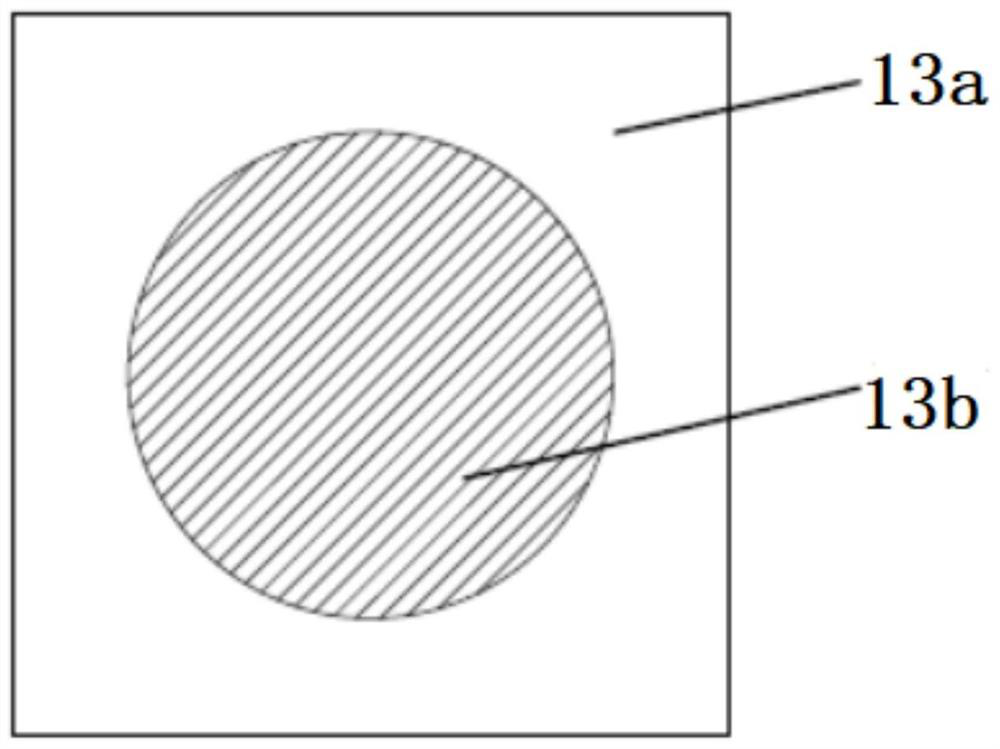

[0058] Z2: epitaxial growth by metal organic chemical vapor phase epitaxy + - GaN epitaxial layers 3a and n - -GaN epitaxial layer 3b, pass into the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com