Water-cooling-heat-pipe dual-mode machine room air conditioner

A computer room air conditioner and cold and heat pipe technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of large energy consumption and large construction investment of refrigeration systems, and achieve energy consumption, High energy consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

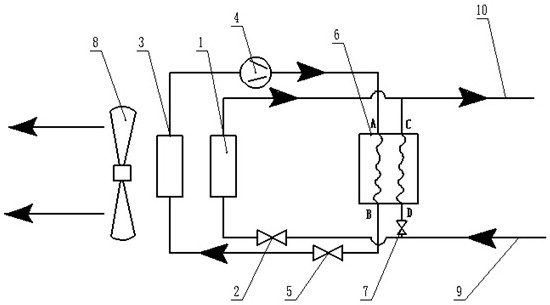

Image

Examples

specific Embodiment approach 1

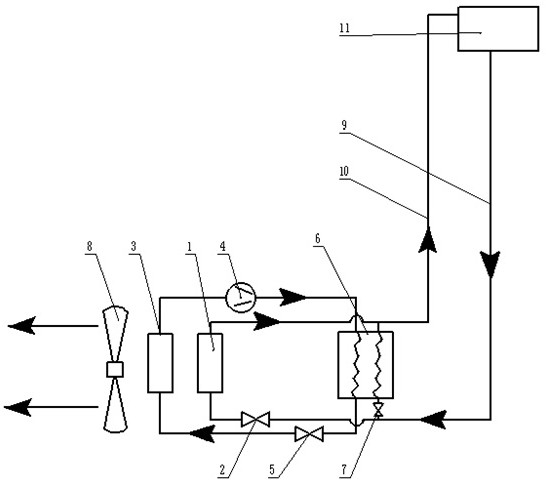

[0031] Please refer to figure 2 As shown, a water-cooled heat pipe dual-mode computer room air conditioner of the present invention also includes an outdoor condenser; the outdoor condenser 11 is communicated between the refrigerant output pipe 10 and the refrigerant input pipe 9; thus, the tube heat exchanger 1 , the refrigerant output pipe 10, the outdoor condenser 11, the hot refrigerant input pipe 9, and the first throttle valve 2 are sequentially connected to form a heat pipe heat exchange system according to the above sequence; the refrigerant of the dual-medium heat exchanger 6 The outlet C of the refrigerant, the refrigerant output pipe 10, the outdoor condenser 11, the refrigerant input pipe 9, the third throttle valve 7, and the 6 refrigerant inlet D of the dual-medium heat exchanger are installed in the above sequence to form a compressor. Outdoor cooling system for refrigeration system.

[0032] The installation position of the outdoor condenser 11 is higher than...

specific Embodiment approach 2

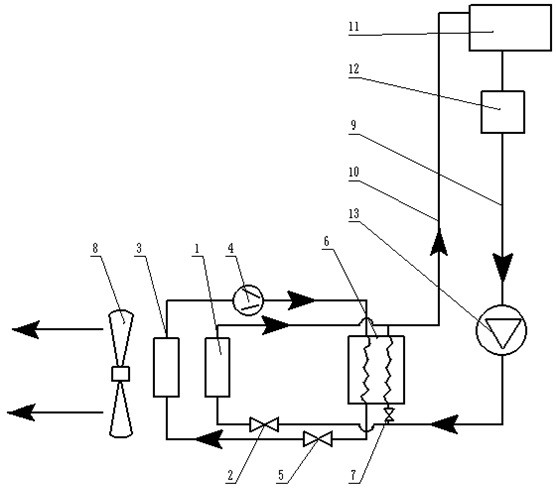

[0037] Please refer to image 3 As shown, compared with Embodiment 1, this embodiment also includes a circulation pump 13 and a liquid storage tank 12; the circulation pump 13 is installed on the refrigerant inlet pipe 9, and the liquid storage tank 12 is installed on the circulation pump 13 and the refrigerant outlet of the outdoor condenser 11, so that the installation position of the outdoor condenser 11 has nothing to do with the positions of the heat pipe heat exchanger 1 and the dual-medium heat exchanger 6. Compared with Embodiment 1, the liquid refrigerant cooled in the outdoor condenser 11 first enters the liquid storage tank 12, and then the circulating pump 13 extracts the refrigerant in the liquid storage tank 12 and sends it to the heat pipe for heat exchange through the first throttle valve 2 1 for heat exchange. At the same time, the circulation pump 13 extracts the refrigerant in the liquid storage tank 12 and sends it to the dual-medium heat exchanger 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com