Processing technology of green pure natural organic lotus leaf tea

A processing technology and technology of lotus leaf tea, which is applied in the field of processing technology of green pure natural organic lotus leaf tea, can solve the problems of dark and soft leaf bottom, thin taste, and heavy green air, so as to improve the overall quality and make the tea soup yellow and green Translucent, mellow and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

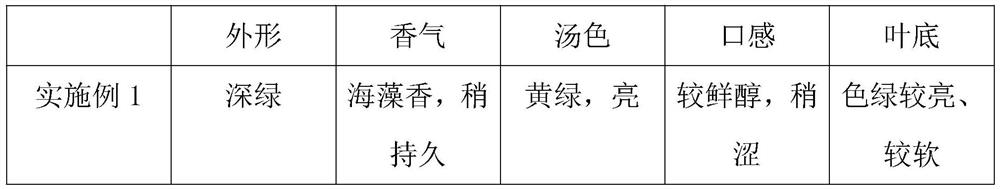

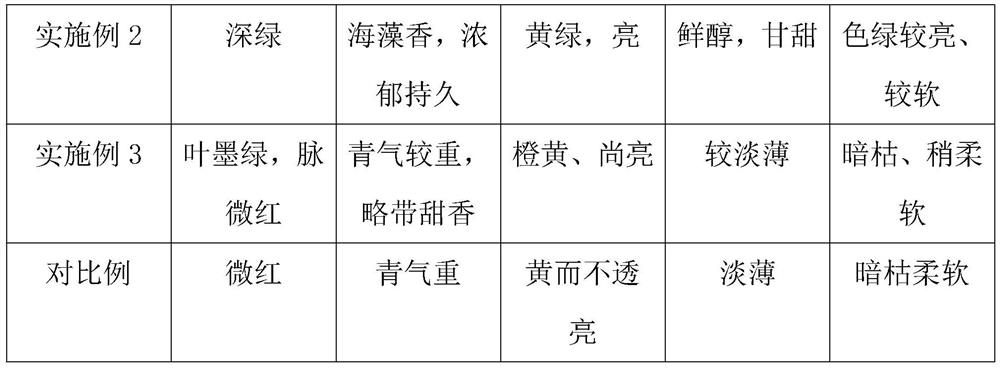

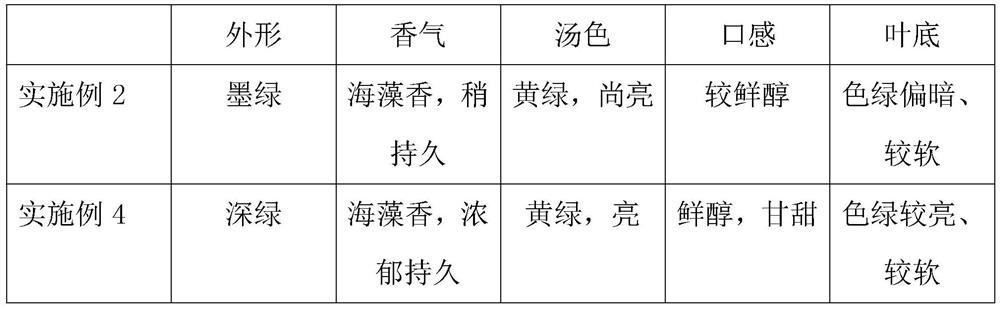

Examples

Embodiment 1

[0027] The invention provides a processing technology of green pure natural organic lotus leaf tea, which specifically comprises the following steps:

[0028] Step 1: Collection: Select the young leaves (commonly known as lotus leaf tea) that are young and tender, have high content of active ingredients, are green in color, and have no disease or insect spots as the raw material of the lotus leaf tea;

[0029] Step 2: Wash and drain: Place the picked lotus leaves one by one in the flowing mountain spring to clean the dirt on the surface, then remove and drain;

[0030] Step 3: Slicing: Cut the drained lotus leaves into diamond-shaped pieces with a side length of 2cm;

[0031] Step 4: Spread green: spread the lotus leaves cut into diamond-shaped pieces evenly on the bamboo strips, and spread the thickness of 3-4cm, and spray one-third of the amount of lotus leaves with a mass fraction of 30% Citric acid solution, spread green for 3-5 hours, and turn it every half an hour. When...

Embodiment 2

[0036] The invention provides a processing technology of green pure natural organic lotus leaf tea, which specifically comprises the following steps:

[0037] Step 1: Collection: Select the young leaves (commonly known as lotus leaf tea) that are young and tender, have high content of active ingredients, are green in color, and have no disease or insect spots as the raw material of the lotus leaf tea;

[0038] Step 2: Wash and drain: Place the picked lotus leaves one by one in the flowing mountain spring to clean the dirt on the surface, then remove and drain;

[0039] Step 3: Slicing: Cut the drained lotus leaves into diamond-shaped pieces with a side length of 2cm;

[0040] Step 4: Spread green: spread the lotus leaves cut into diamond-shaped pieces evenly on the bamboo strips, and spread the thickness of 3-4cm, and spray one-third of the amount of lotus leaves with a mass fraction of 30% Citric acid solution, spread green for 3-5 hours, and turn it every half an hour. When...

Embodiment 3

[0045] The invention provides a processing technology of green pure natural organic lotus leaf tea, which specifically comprises the following steps:

[0046]Step 1: Collection: Select the young leaves (commonly known as lotus leaf tea) that are young and tender, have high content of active ingredients, are green in color, and have no disease or insect spots as the raw material of the lotus leaf tea;

[0047] Step 2: Wash and drain: Place the picked lotus leaves one by one in the flowing mountain spring to clean the dirt on the surface, then remove and drain;

[0048] Step 3: Slicing: Cut the drained lotus leaves into diamond-shaped pieces with a side length of 2cm;

[0049] Step 4: Spread green: spread the lotus leaves cut into diamond-shaped pieces evenly on the bamboo strips, and spread the thickness of 3-4cm, and spray one-third of the amount of lotus leaves with a mass fraction of 30% Citric acid solution, spread green for 3-5 hours, and turn it every half an hour. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com