Solid aromatherapy product and preparation method thereof

An aromatherapy and solid technology, applied in separation methods, chemical instruments and methods, colloid chemistry, etc., can solve problems such as gel strength to be improved, and achieve the effects of increasing strength, stabilizing the gel system, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

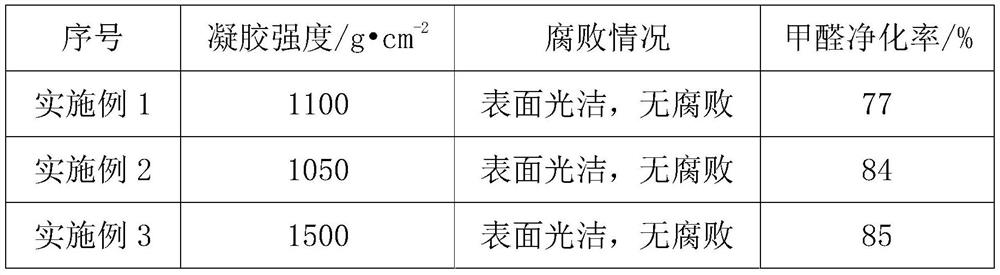

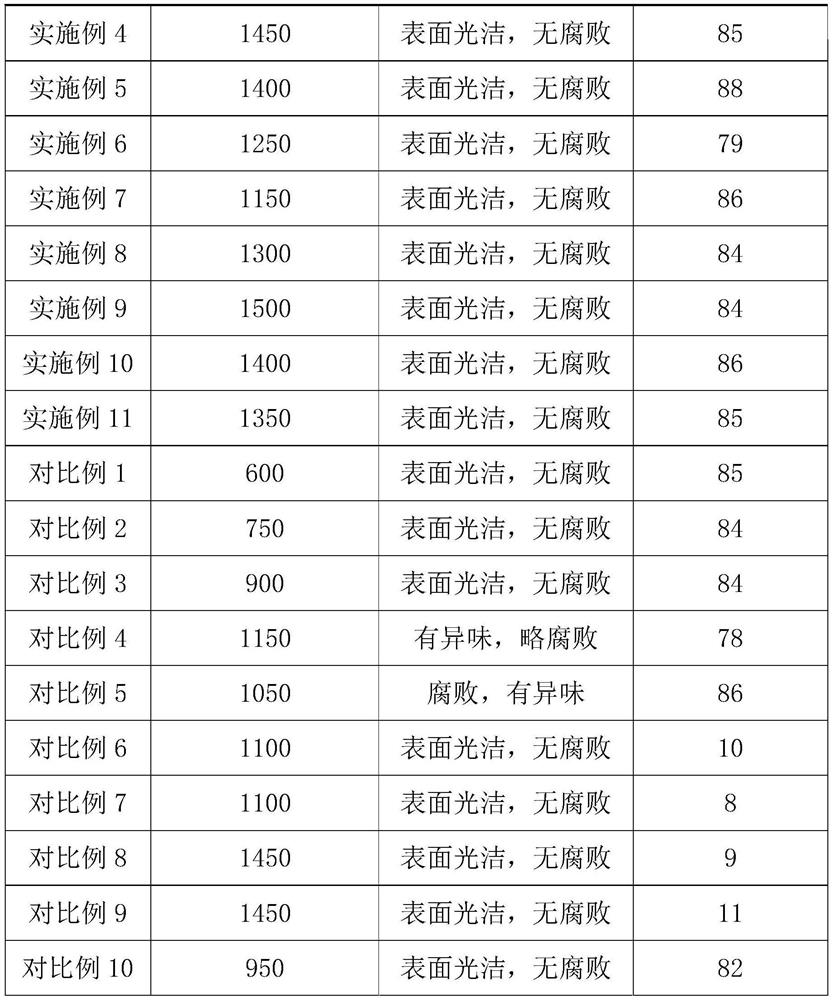

Examples

preparation example 1

[0046] Weigh 100g of fresh creeper leaves and crush them. The pulverized material was placed in 500ml of ethanol (concentration: 85wt%), and soaked for 2.5h under the action of ultrasonic waves, the frequency of which was 60KHz. Afterwards, at a temperature of 30° C., the mixed system was placed in an airtight container and stood still for 18 hours; then, it was centrifuged at 550 rpm for 12 minutes, and the supernatant was taken. The third plant liquid was obtained after filtering the supernatant through a ceramic membrane with a pore size of 0.45 μm.

preparation example 2

[0048] Weigh 100g of fresh tiger Pilan leaves and pulverize; place the pulverized product in 800ml of ethanol (concentration: 85wt%), and soak for 1h under the action of ultrasonic waves, the frequency of which is 80KHz. Afterwards, at a temperature of 30° C., the mixed system was placed in an airtight container and stood still for 20 hours; then, it was centrifuged at 550 rpm for 10 minutes, and the supernatant was taken. The third plant liquid was obtained after filtering the supernatant through a ceramic membrane with a pore size of 0.45 μm.

preparation example 3

[0050]100 g of fresh clover leaves were weighed and pulverized; the pulverized product was placed in 300 ml of ethanol (concentration: 85 wt %), and soaked for 5 h under the action of ultrasonic waves with a frequency of 40 KHz. Afterwards, at a temperature of 30° C., the mixed system was placed in an airtight container and stood still for 36 hours; then, it was centrifuged at 500 rpm for 15 minutes, and the supernatant was taken. The third plant liquid was obtained after filtering the supernatant through a ceramic membrane with a pore size of 0.45 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com