Pretreatment device before corn particle processing and corn flour production method

A pretreatment device and corn granule technology, applied in seed and rhizome treatment, grain treatment, application, etc., can solve the problems of air pollution, difficult cleaning, easy clogging, etc., and achieve the goal of reducing feeding time, increasing speed and preventing clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

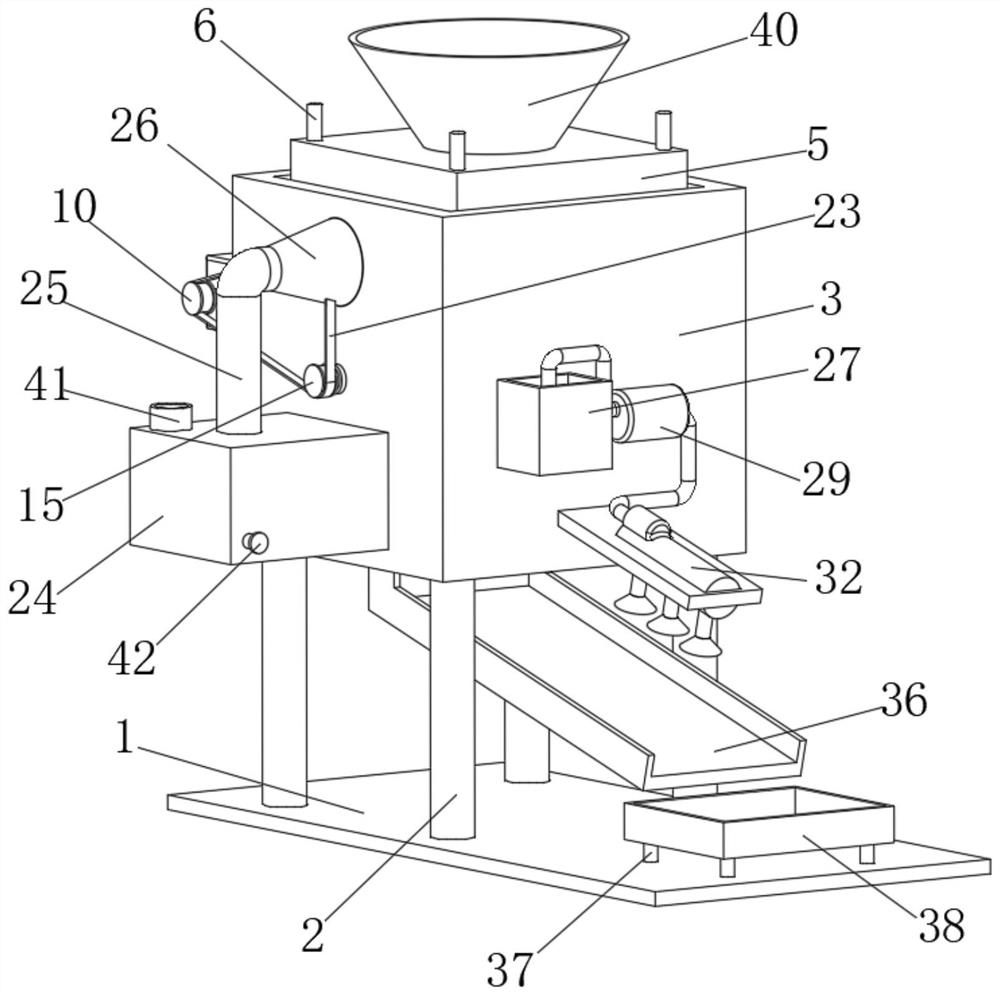

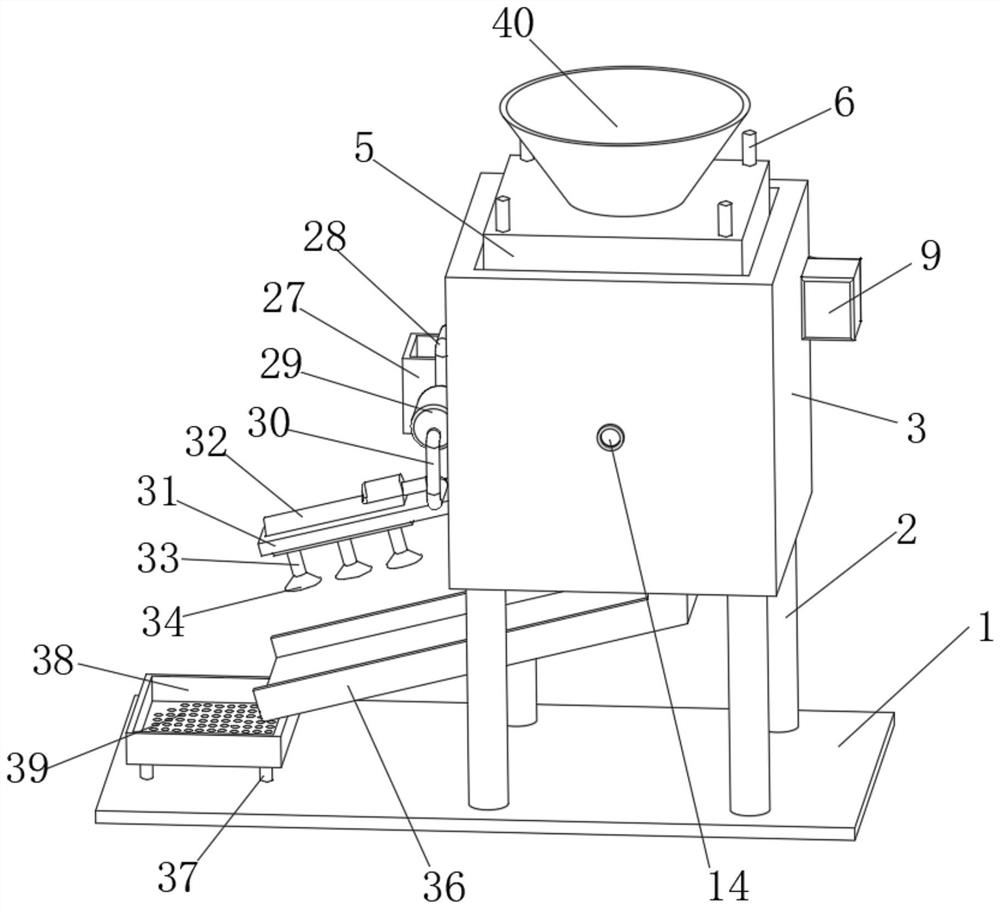

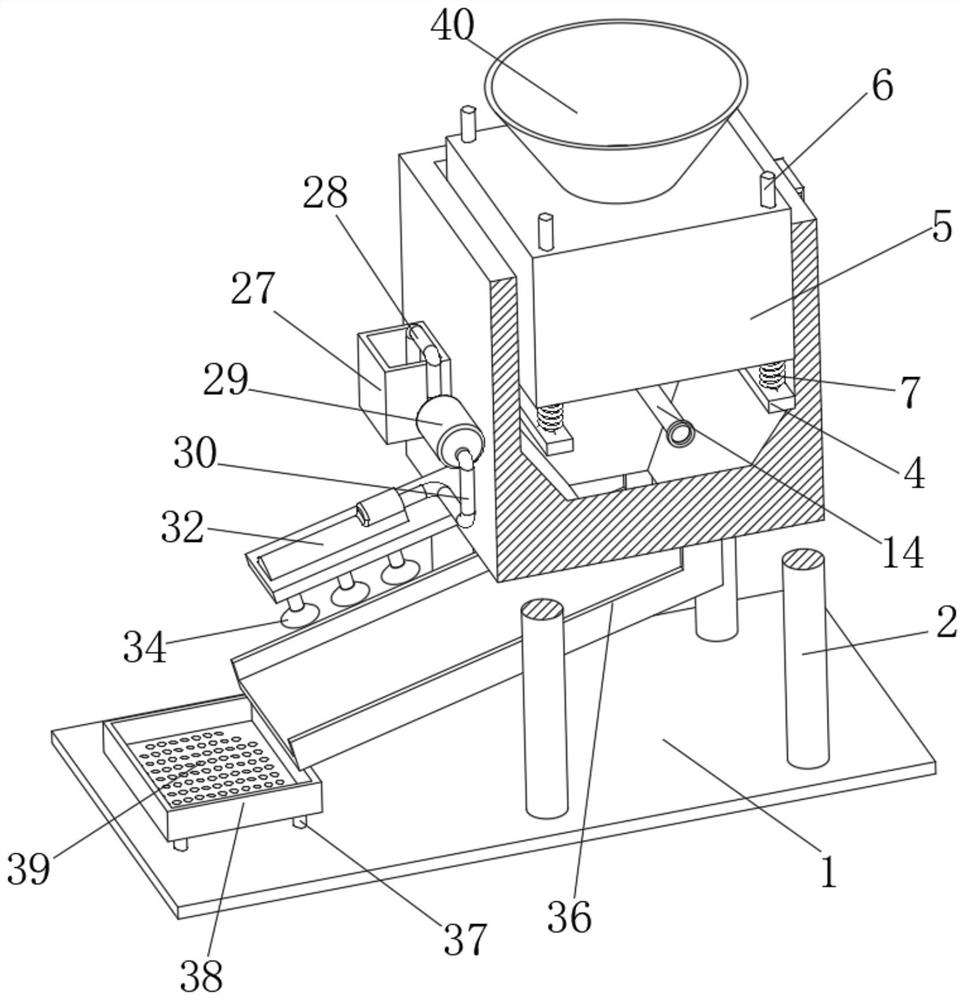

[0035] In a typical implementation of the present application, such as Figure 1-8 As shown, a pretreatment device before corn grain processing includes a bottom plate 1, four support columns 2 are fixedly connected to the top of the bottom plate 1, and the tops of the four support columns 2 are fixedly connected to the same external fixed box 3, and the external fixed Two fixed connecting plates 4 are fixedly connected on one side inner wall of the box 3, and the other ends of the two fixed connecting plates 4 are all fixedly connected on the other side inner wall of the outer fixed box 3, and the tops of the two fixed connecting plates 4 are fixed Two guide rods 6 are connected, and the outer fixed box 3 is provided with a shaking lower material box 5, and the top of the shaking lower material box 5 is provided with four guide holes, and the top ends of the four guide rods 6 respectively pass through the four guide holes and extend To the outside of the corresponding guide h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com