Sensor-based internal thread detection method for pipe fittings, pipe fitting screening method and system

A detection method and sensor technology, applied in the field of internal threads, can solve the problems of small size threads and low thread depth detection accuracy, and achieve the effect of high-efficiency online detection and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

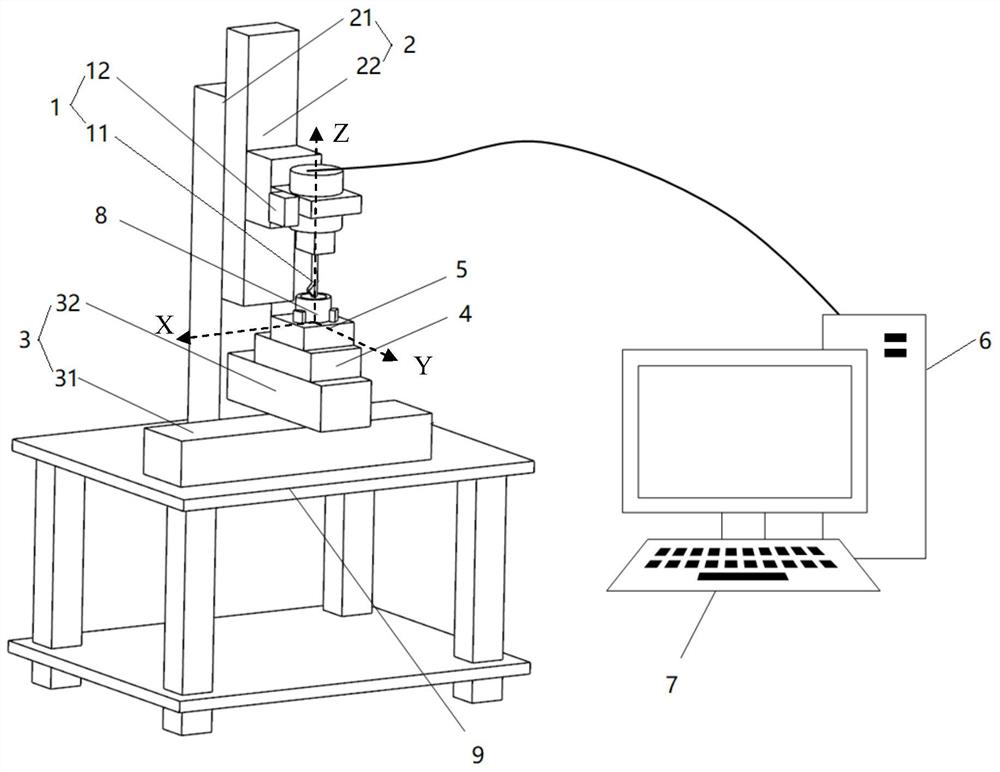

Image

Examples

Embodiment 1

[0053] In practical engineering, there is often a problem that the wall thickness of the pipe fittings along the radial direction is not uniform due to factors such as processing errors, so that the inner and outer walls of the pipe fittings are not coaxial. image 3 Shown is a schematic diagram of a pipe fitting where the inner and outer walls are not coaxial. Aiming at the detection of the inner thread of the pipe whose inner and outer walls are not coaxial, this embodiment discloses a sensor-based method for detecting the inner thread of the pipe. The inner thread of the pipe to be tested in this embodiment is a straight thread, that is, the Internally threaded holes are circular holes of equal diameter. The method includes the following steps:

[0054] Step 1, determine the axis position of the outer wall of the pipe to be tested;

[0055] In this embodiment, the pipe to be tested is preferably passed through the center of the circle in the space coordinate system. Speci...

Embodiment 2

[0068] In this embodiment, the inner thread of the pipe to be tested is a tapered thread, that is, the inner threaded hole of the pipe to be tested is tapered, such as Figure 5 shown. The difference between the internal thread detection method of this embodiment and Embodiment 1 is:

[0069] Step 3, when the inner circle of the pipe to be measured is conical, the horizontal position of the horizontal distance sensor is adjusted in real time during the axial movement of the horizontal distance sensor along the axis of the pipe to be measured. Make sure that the inner thread surface of the pipe to be tested is within the range of the horizontal distance sensor.

[0070] The detection method of the invention solves the problem that the traditional detection method cannot determine the axis of the inner wall of the workpiece when the inner and outer walls of the workpiece are not coaxial due to factors such as machining errors, so that the measured pitch diameter of the thread i...

Embodiment 3

[0073] The present embodiment discloses a method for screening pipe fittings based on a sensor. The method is used to screen out qualified and unqualified pipe fittings with internal threads. The method includes the following steps:

[0074] Step 1, determine the specification type of the pipe to be tested, the specification type in this embodiment includes the outer diameter, inner diameter, wall thickness and height of the pipe to be tested;

[0075] This embodiment specifically includes: a vertical distance measuring sensor 11 is arranged above the pipe to be measured, and the vertical distance sensor 11 moves from a point outside the outer wall of the pipe to be measured to the outer wall of the pipe to be measured along a horizontal direction intersecting with the axis of the outer wall of the pipe to be measured. At another point outside, the specification type of the pipe to be measured is obtained according to the signal change of the vertical ranging sensor.

[0076] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com