Automatic assembling equipment for mini electromagnetic valve

An automatic assembly and solenoid valve technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of high assembly cost and low degree of automatic assembly automation, and achieve the goal of reducing investment, improving work efficiency and reducing economic expenses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

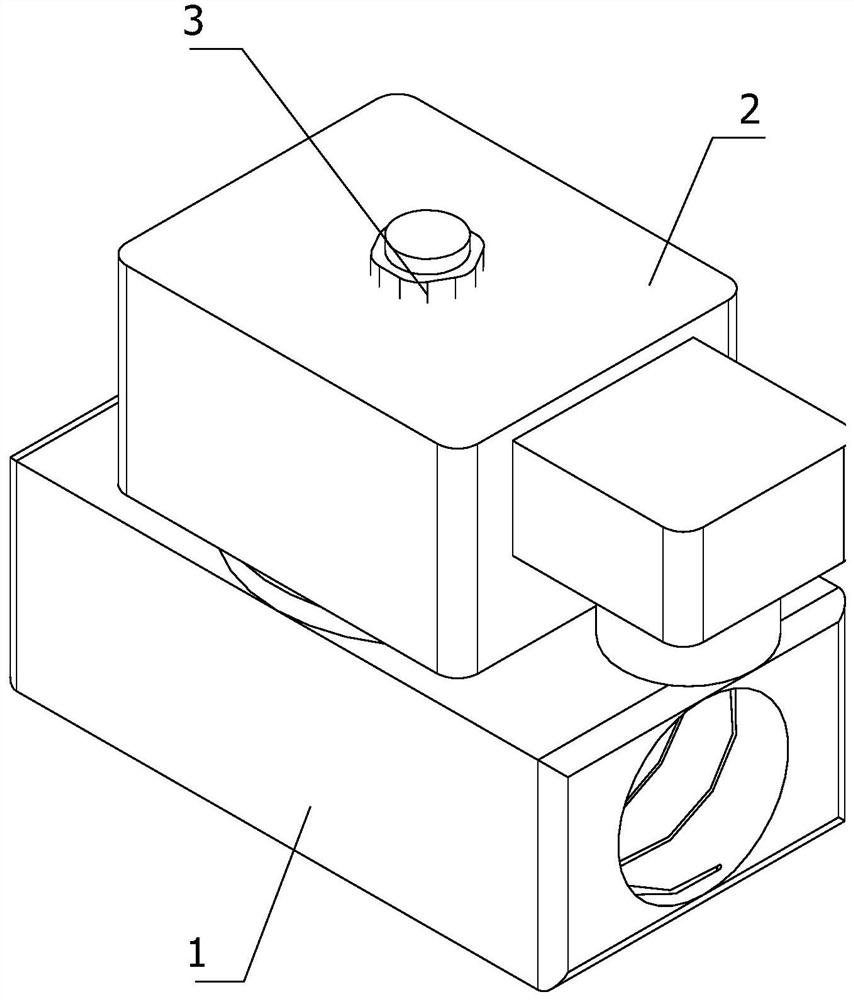

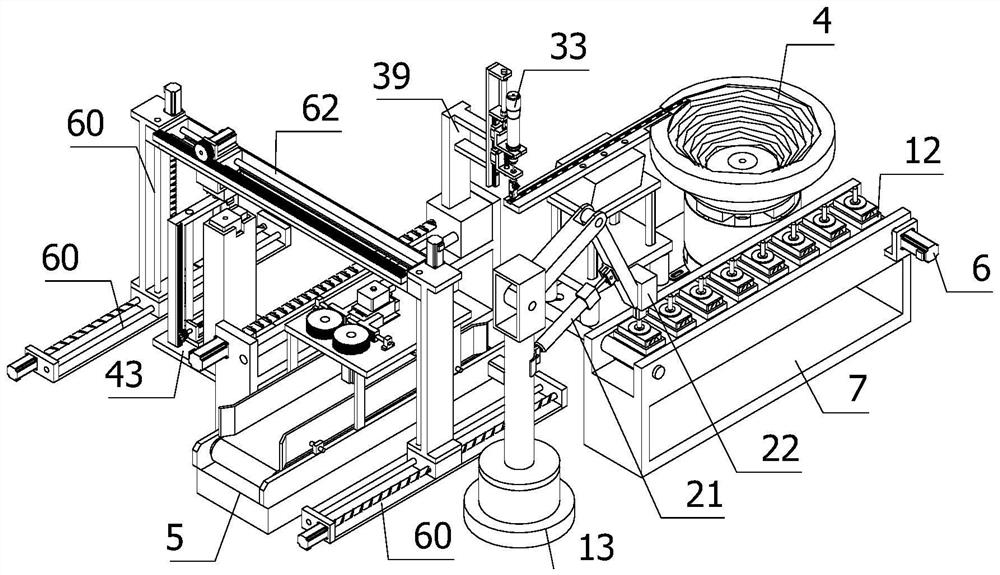

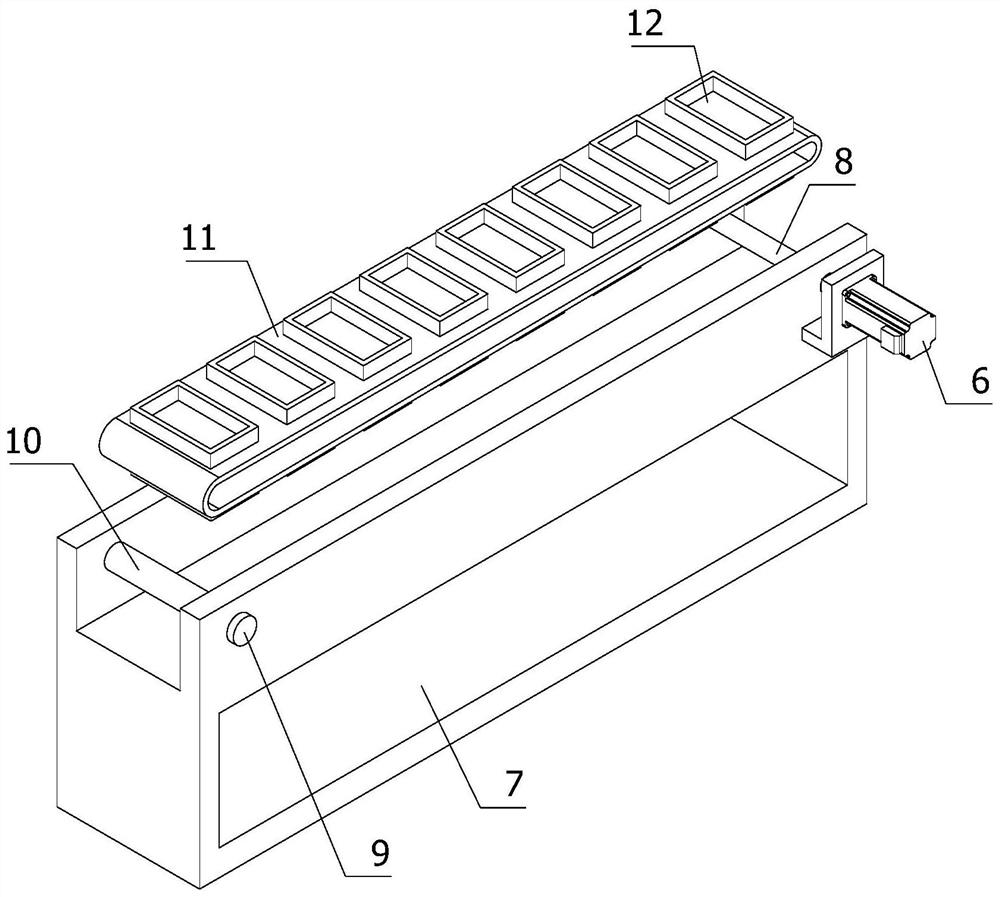

[0040] refer to Figure 1 to Figure 11 As shown, an automatic assembly equipment for a mini solenoid valve, including a feeding mechanism, a rotary clamping mechanism, a first assembly assembly, a second assembly assembly, a lifting mechanism and a blanking assembly; first place the valve seat 1 on the loading assembly , the loading assembly transports the valve seat 1 to the rotary clamping mechanism, and then the rotary clamping mechanism transports the valve seat 1 to the unloading assembly, and then the lifting mechanism moves the valve body 2 upwards. At the same time, the second assembly assembly Move to the top of the lifting mechanism, grab the valve body 2 and move it to the valve seat 1 at the blanking assembly, put the valve body 2 into the valve seat 1, and then the first assembly component transports the nut 3 to the blanking assembly, and put the nut 3. Screw together with the valve seat 1 and the valve body 2. After screwing, transport the assembled mini solenoi...

Embodiment 2

[0056] Compared with Embodiment 1, in this embodiment, the stabilizing mechanism includes a fixed frame 48, a fifth motor 49, a cross bar 50, a fixed rod 51, two fourth gears 52, two extrusion blocks 53 and two shaft seats 54, the fixed frame 48 is vertically arranged on the top of the conveyor belt 5, the top of the fixed frame 48 is provided with a rectangular groove 55 and two protrusions 56, and the two shaft seats 54 are spaced apart and arranged parallel to each other on the fixed frame 48 The two ends of a protrusion on the top, the two ends of the cross bar 50 are connected with two shaft seats 54, the two extruding blocks 53 are sleeved on the two ends of the cross bar 50, and the ends of the two extruding blocks 53 away from the protrusion are arranged There are tooth marks 57, a fourth gear is arranged on the top of the fixed frame 48 near one end of the extrusion block that has the tooth marks 57, and the other fourth gear is arranged on the top of the fixed frame 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com