Humanoid robot and joint thereof

A humanoid robot and joint technology, applied in the field of humanoid robots, can solve the problems of increasing the structural moment of inertia, reducing the strength of the mechanism, and difficult cable layout, etc., and achieve the effects of reducing inertia, reducing module weight, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

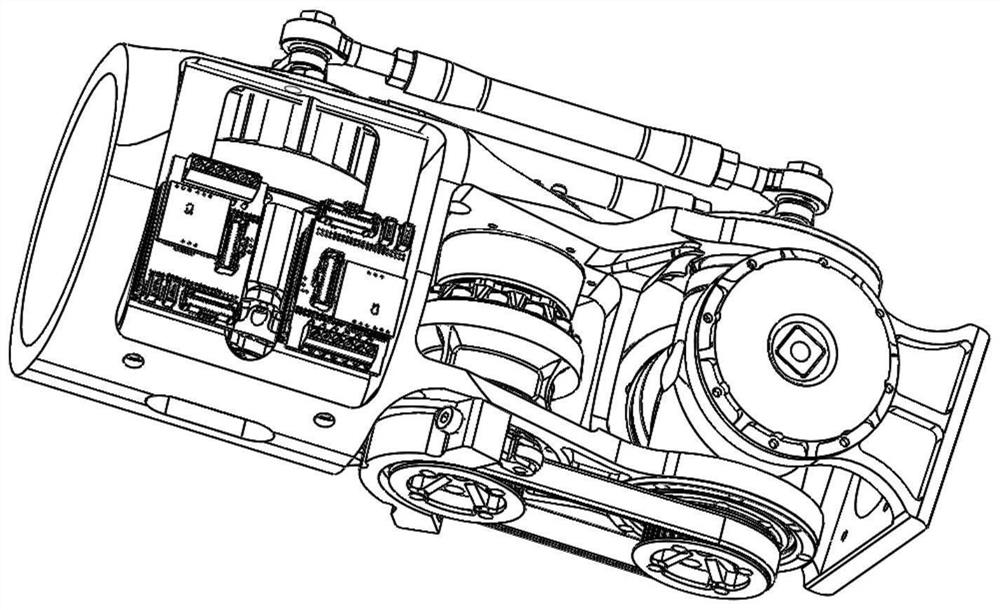

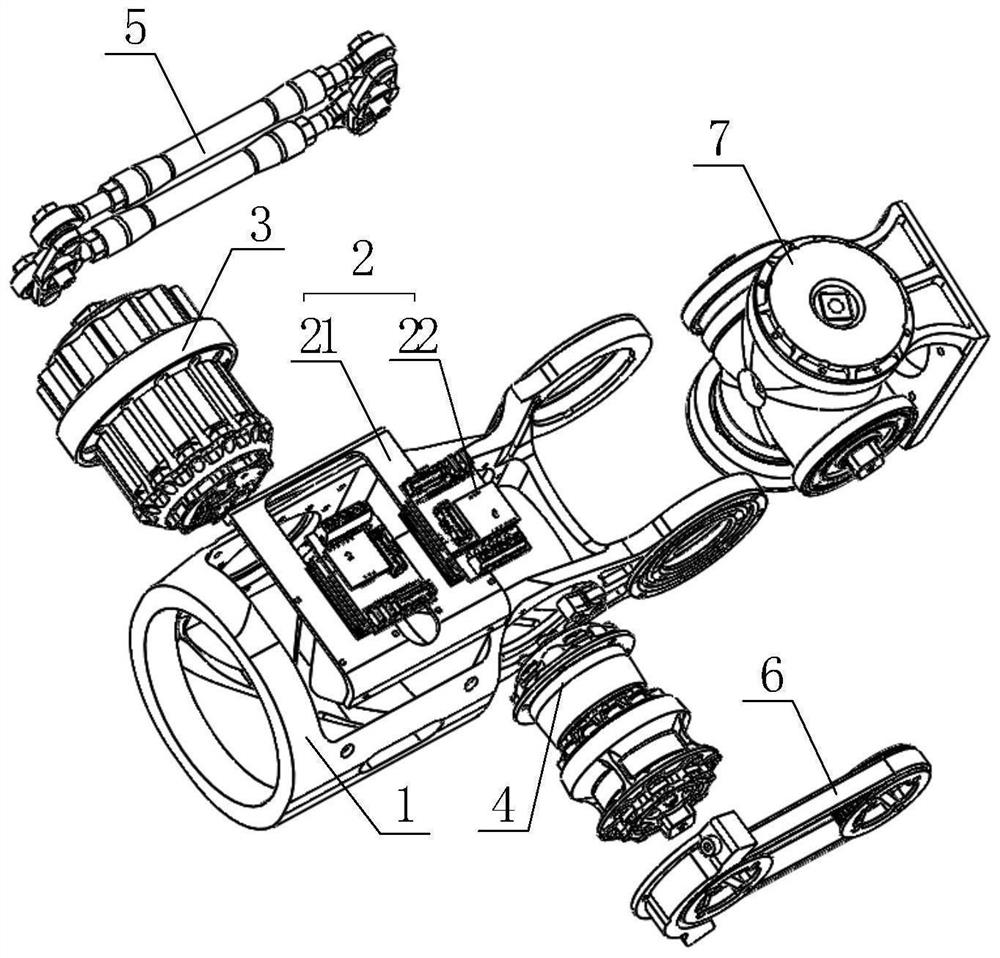

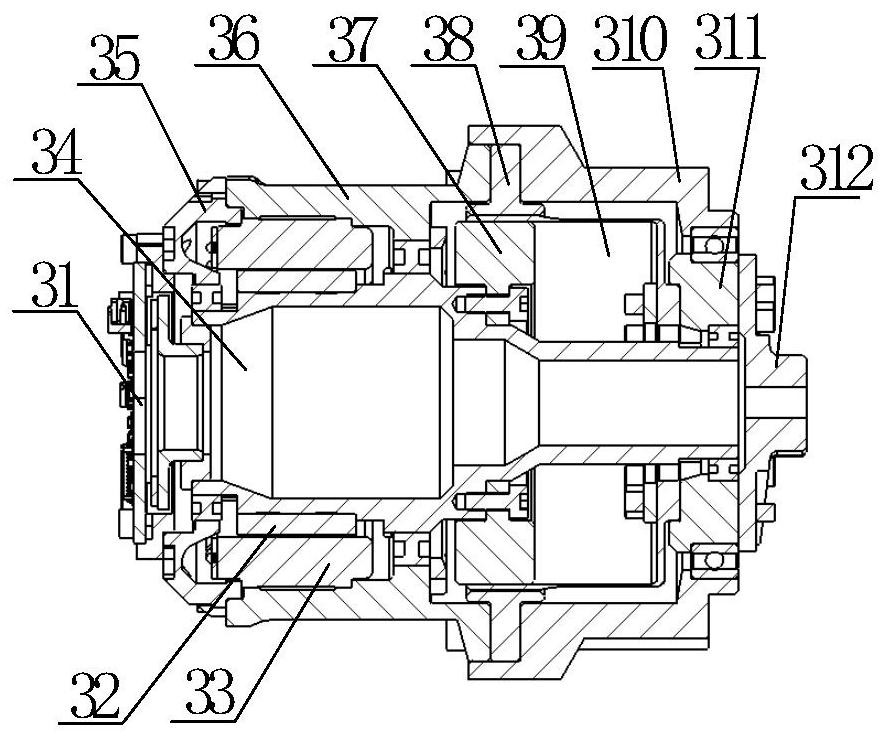

[0038] Such as figure 1 , 2As shown, the humanoid robot joint of the present invention is composed of a joint frame 1 , a driver module 2 , a first drive module 3 , a second drive module 4 , a connecting rod transmission module 5 , a synchronous belt transmission module 6 and a cross axis joint module 7 .

[0039] Such as figure 1 and figure 2 As shown, the joint frame 1 is used as the main frame of the humanoid robot joint, and adopts an integrated structure, which is similar to the shape of "冃" as a whole. The joint frame 1 away from the execution end is a hollow cylinder, and the joint frame 1 near the execution end is two opposite pieces. shape structure, and a pair of through holes are provided on the sheet structure; along the direction of the execution end, the first drive module 3, the second drive module 4 and the cross-axis joint module 7 are sequentially fixed in the joint frame 1, and the hollow cylindrical joint frame 1 is fixed with a driver module 2, and the...

Embodiment 2

[0051] A humanoid robot, including the humanoid robot joint in Embodiment 1, its structural features have been described in detail in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com