A fiber-reinforced composite material imitating the structure and function of scorpion pincers

A composite material and fiber-reinforced technology, applied in the field of composite materials, can solve the problems of less research, difficulty in replication and synthesis, etc., and achieve the effects of improving fracture toughness, reducing shear strain, and improving bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention and their specific operations are described herein, which will be further described in detail below with reference to the accompanying drawings and examples.

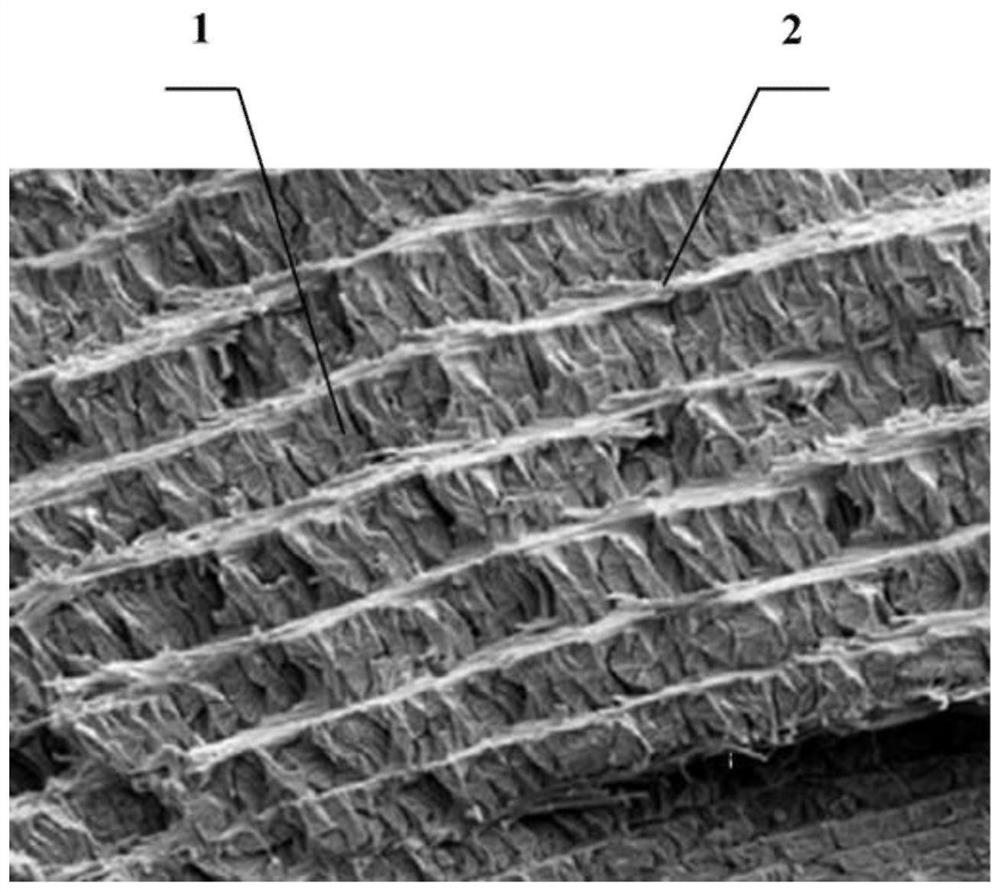

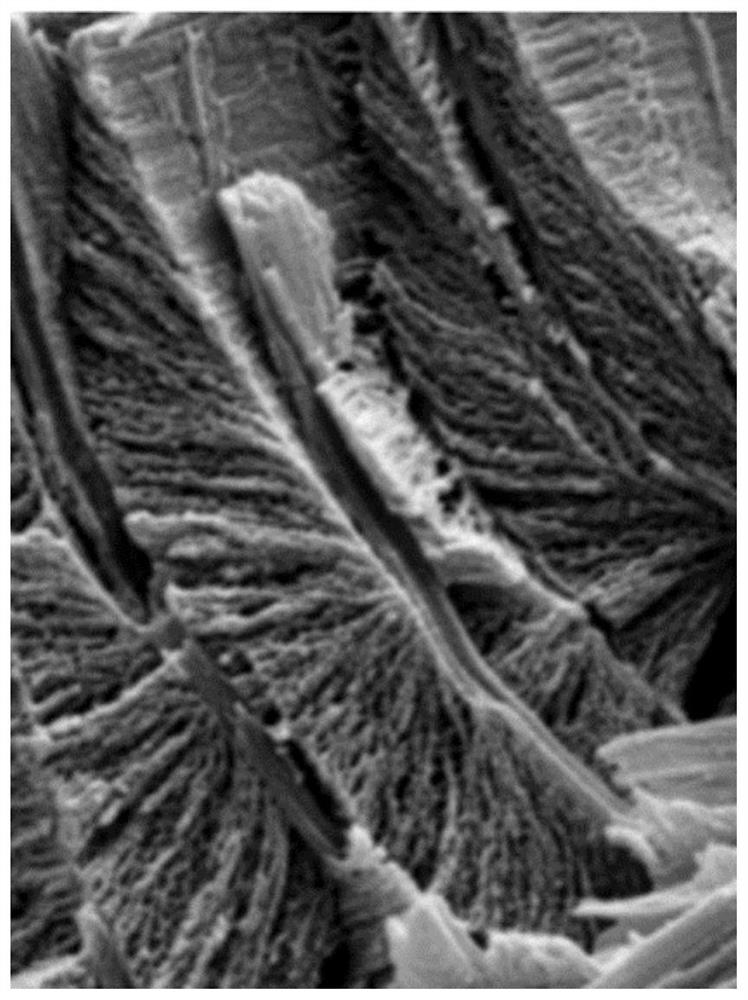

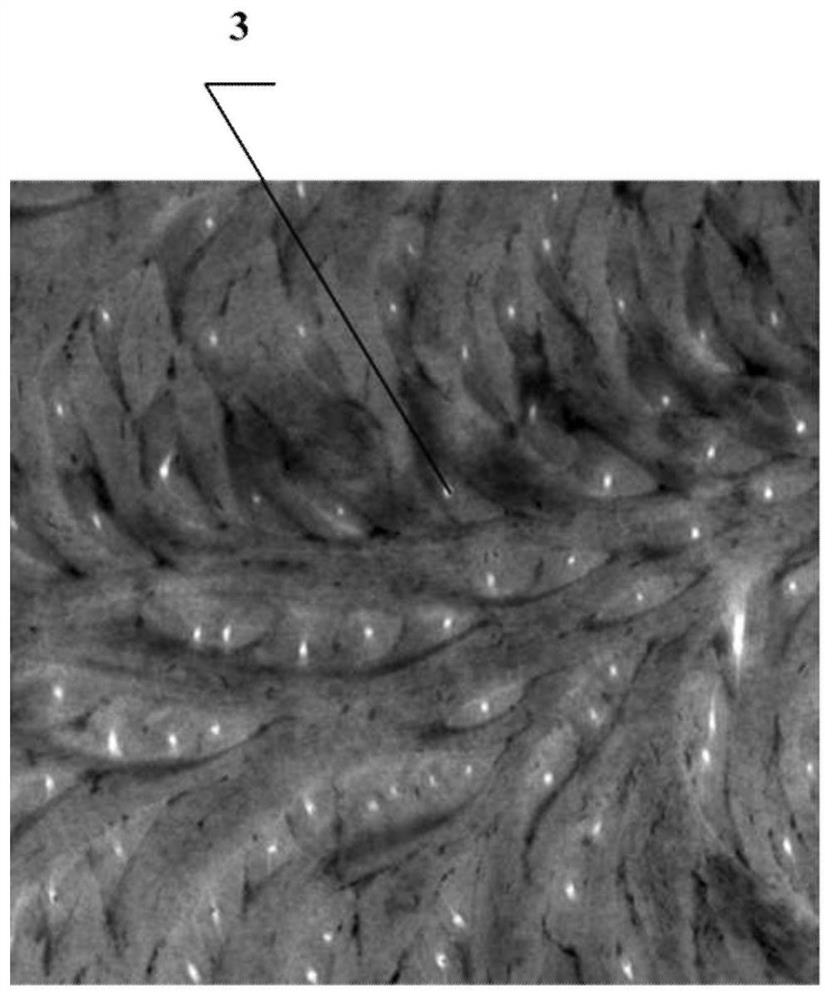

[0037] The inner surface skin of the scorpion chelate is mainly nestled from a plurality of helical structures formed by twisting and inclined. figure 1 Indicated. The helical structure is arranged in a three-dimensional space, separated by the collagen fiber layer 2. In the laminated hole 3, such as image 3 As shown, the pore fibers in the scorpion zone are hollow structures, and can be used as a transmission conduit, such as minerals required for transmission, etc., and also have mechanical properties, which can improve the surface stiffness.

[0038] like Figure 4-9 As shown, the laying method of a bionic fiber reinforced composite fiber layer in the present invention is based on the sequence of collagen fibers in the scorpion chelate, and is nested by a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com