Acoustic reinforcing material block and manufacturing method and application thereof

A technology for enhancing materials and acoustics, applied in applications, other household appliances, household appliances, etc., can solve problems such as incomplete filling, affecting performance, and damaging speakers, and achieve good sound quality and excellent sound performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

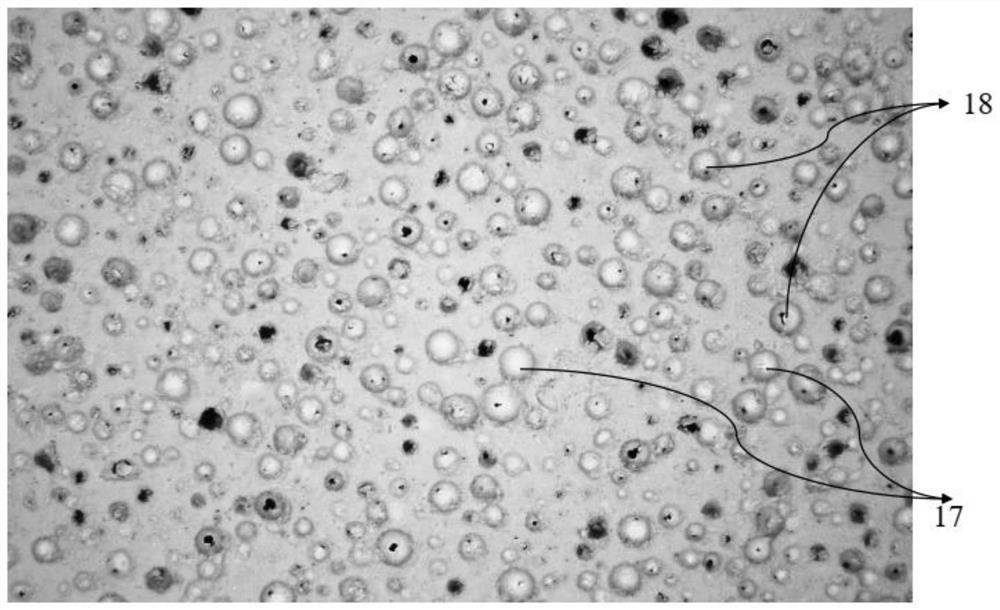

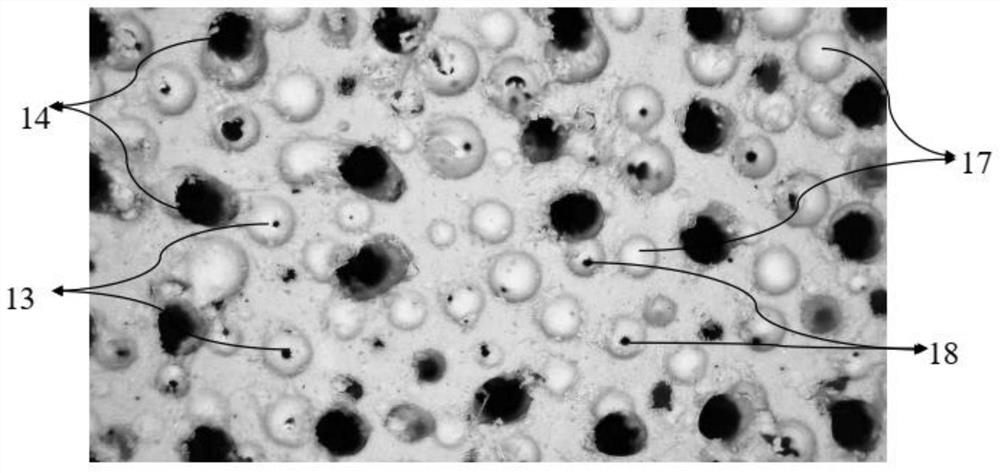

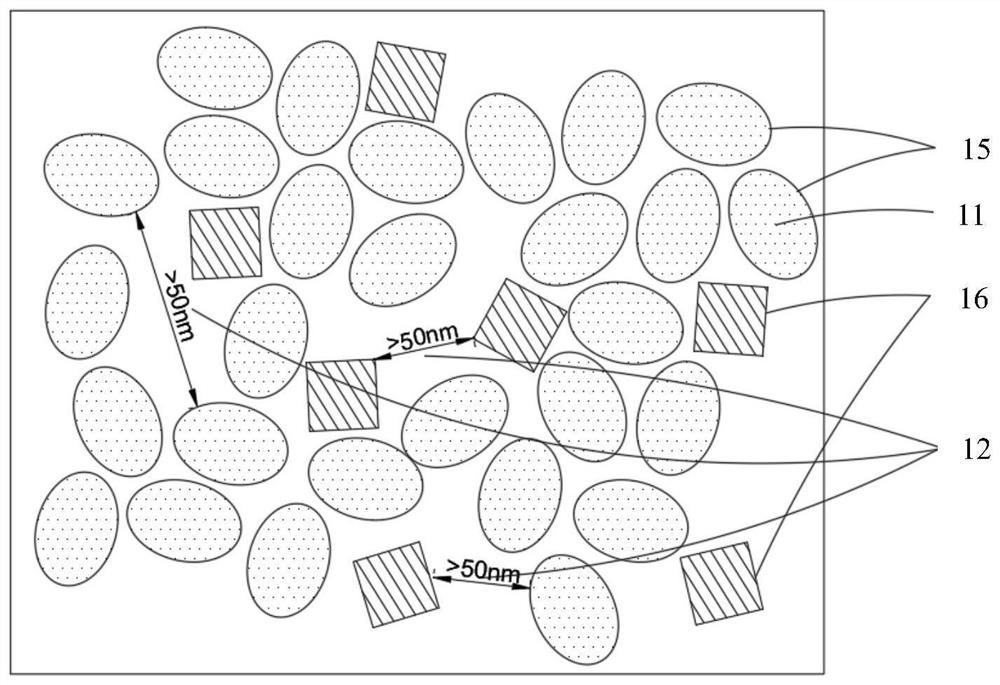

Image

Examples

Embodiment 1

[0110] This embodiment provides an acoustic reinforcement material block, which is prepared by a method comprising the following steps:

[0111] (1) Mix 50g of water, 50g of molecular sieve particles (zeolite particles, with an average particle size of 1.4μm), 2.5g of filler (mica powder), 2g (in terms of solid content) of organic binder (polyacrylate suspension), 0.1 g hydrogen peroxide and 0.05g thickener (CMC) are fully stirred and mixed uniformly to obtain a homogeneous mixture;

[0112] (2) injecting the mixture into a mold at room temperature, and immersing the mold in liquid nitrogen to rapidly cool the mixture down to below -20°C to obtain a frozen-formed mixture;

[0113] (3) performing freeze-drying treatment on the freeze-shaped mixture, the temperature of the freeze-drying treatment is -40°C to -90°C, and the time is 6h;

[0114] (4) Put the freeze-dried product into an oven with a temperature higher than 100° C. for baking and dehydration treatment for 3 hours to...

Embodiment 2

[0118] This embodiment provides an acoustic reinforcement material block, which is prepared by a production method comprising the following steps:

[0119] (1) 50g of water, 50g of molecular sieve particles (zeolite particles, average particle size of 1.4μm), 2.5g of filler (mica powder) 15, 2g (in terms of solid content) organic binder (polyacrylate suspension), 0.1g hydrogen peroxide and 0.05g thickener (CMC) are fully stirred and mixed uniformly to obtain a homogeneous mixture;

[0120] (2) injecting the mixture into a mold at room temperature, and immersing the mold in liquid nitrogen to rapidly cool the mixture down to below -20°C to obtain a frozen-formed mixture;

[0121] (3) performing freeze-drying treatment on the freeze-formed mixture, the temperature of the freeze-drying treatment is -40°C to -90°C, and the time is 6h;

[0122] (4) Put the freeze-dried product into an oven with a temperature greater than 100° C. for baking and dehydration for 3 hours;

[0123] (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com