Processing method and device for spinning single yarns of plied yarn structures on ring spinning frame and yarns

A spinning frame and yarn stranding technology, which is applied to spinning machines, textiles, papermaking, yarn, etc., can solve problems such as low yarn strength, complicated spinning process, and reduced production efficiency, so as to increase yarn strength and shorten the process. process, the effect of improving yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

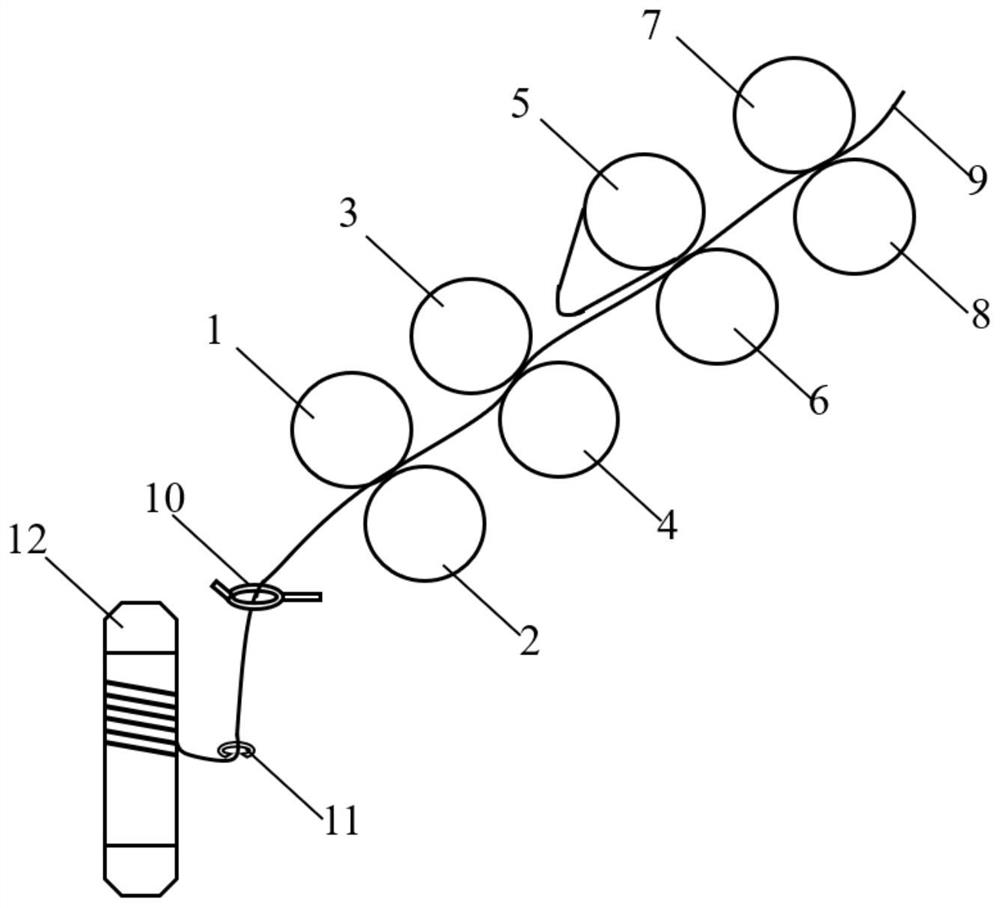

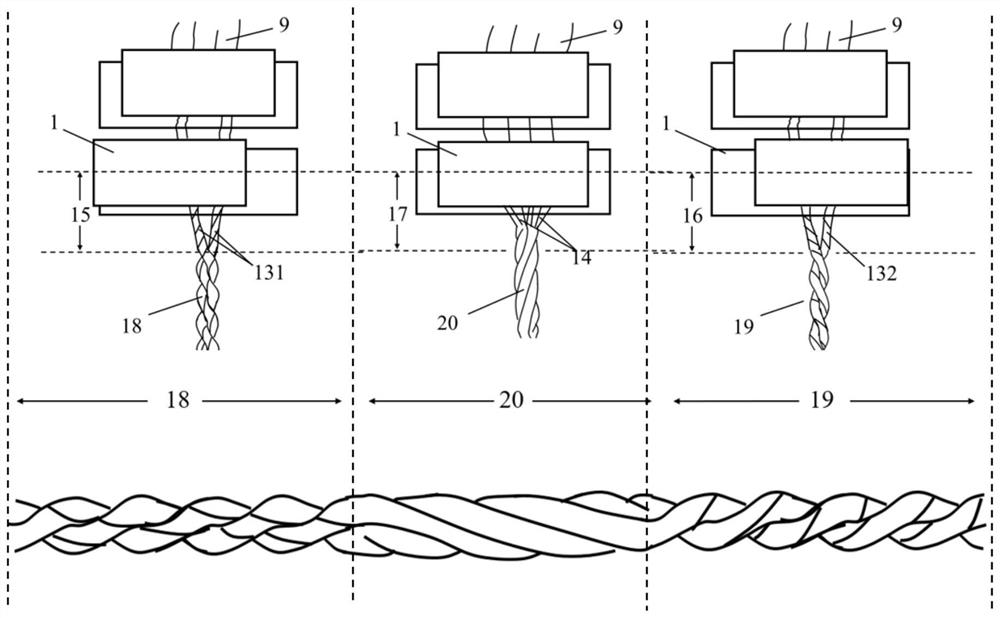

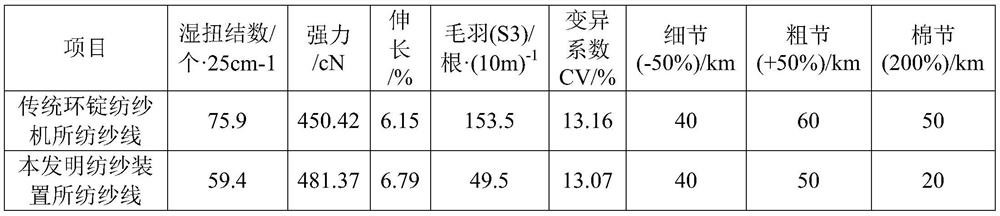

[0026] Use the spinning method of the patent of the present invention to produce 19.7tex yarn. The raw materials used in the experiment were two bundles of 100% cotton rovings. The spindle speed of the ring spinning machine is 7000r / min. The twisting mechanism traverse distance is 3cm, the traverse rate is 2m / min, the reciprocating and turning frequency is 15 times / min, the pressure between the twisting roller and the twisting roller is 100N, the diameter of the twisting roller is 3cm, and the height is 8cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com