Production process and production equipment of rayon cotton and linen product cloth

A production process and rayon technology, applied in the field of printing and dyeing process, can solve the problems of cloth color difference, large cloth batch difference, etc., and achieve the effect of small process difference, reduced waste, and reduced use of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

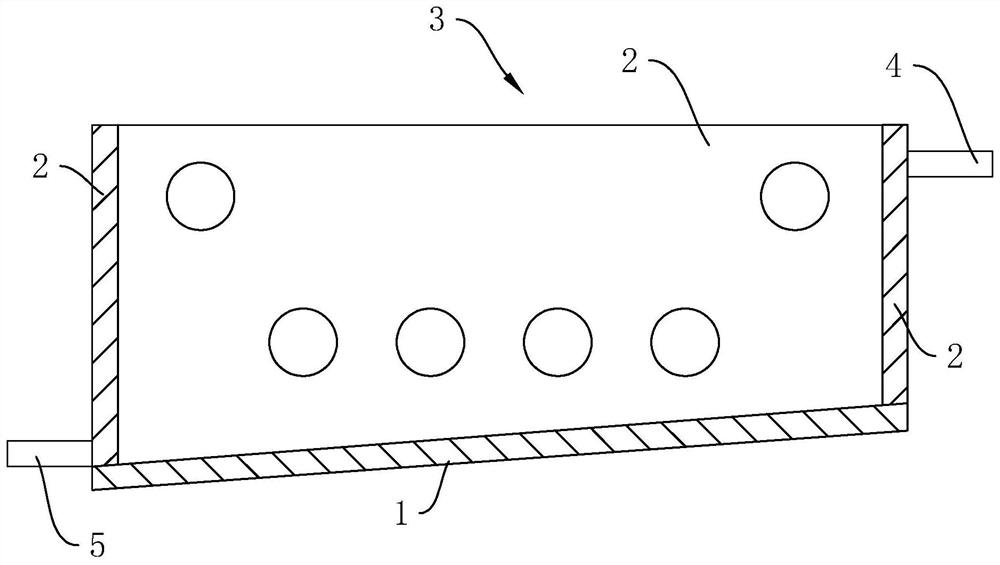

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of production technology of rayon cotton linen product cloth, comprises the following steps:

[0037] S1: Leveling: pass the fabric through the fabric leveling machine at a speed of 45m / min, with three washing tanks, and the temperatures are 40°C, 80°C and 60°C in sequence to obtain the leveled fabric;

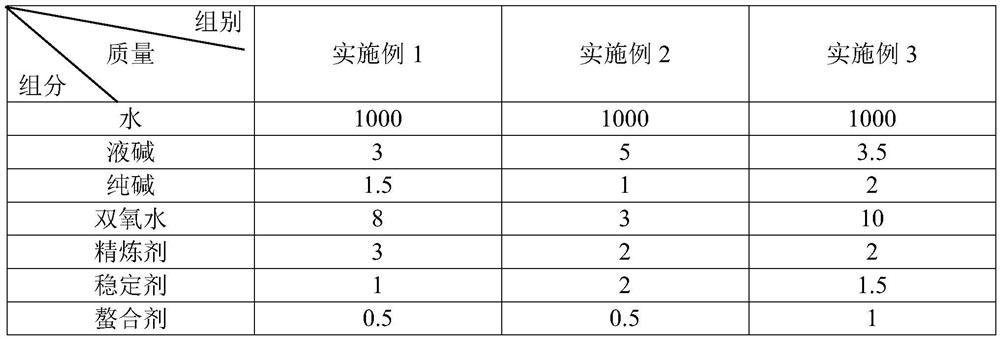

[0038] S2: Oxygen bleaching: add the oxygen bleaching agent into the oxygen bleaching tank, and heat the oxygen bleaching agent to 40°C and keep it warm. The fabric is continuously passed through the oxygen bleaching agent at a speed of 40m / min, and the oxygen bleaching continues for 24 hours per 1000m of fabric; When bleaching is in progress, continuously add oxygen bleaching agent into the oxygen bleaching tank. Configuration of oxygen bleaching agent: put each component into the stirring tank, and stir for 3 minutes at a stirring speed of 30r / min until the solution is uniform;

[0039] S3: Water washing: Wash the fabric after oxygen bleaching tw...

Embodiment 2

[0042] Embodiment 2: A production process of rayon, cotton and linen product cloth, the difference from Embodiment 1 is: S2: Oxygen bleaching: the heating temperature of the oxygen bleaching agent is 50°C, and the speed of the cloth passing through the oxygen bleaching agent is 90m / min; See Table 1 for the components of the oxygen bleaching agent and the corresponding quality; the oxygen bleaching lasts for 22 hours per 1000m of fabric.

Embodiment 3

[0043] Embodiment 3: A production process of rayon, cotton and linen products, the difference from Embodiment 1 is: S2: Oxygen bleaching: the heating temperature of the oxygen bleaching agent is 30°C, and the speed of the cloth passing through the oxygen bleaching agent is 50m / min; See Table 1 for oxygen bleach components and corresponding quality.

[0044] Oxygen bleaching agent components and corresponding quality (kg) in table 1 embodiment 1-3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com