Water stop buckle for leaking stoppage

A water buckle and waterproof material technology, applied in the field of water stop buckle and plugging, can solve the problems of short effective time, low success rate, poor water plugging effect, etc., and achieve the effect of ensuring the plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

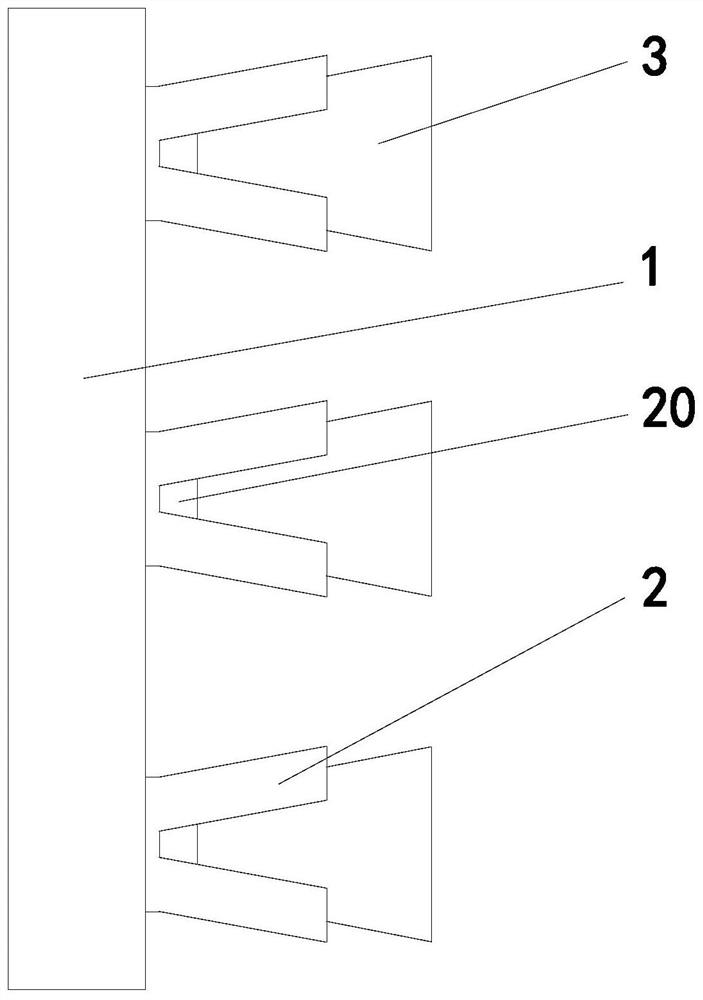

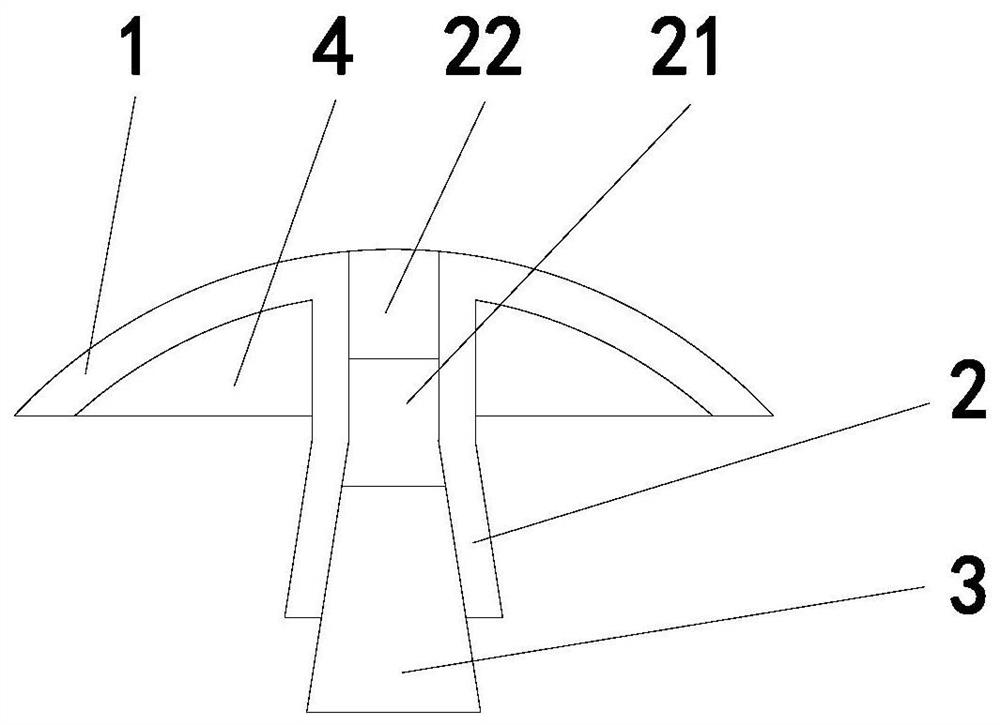

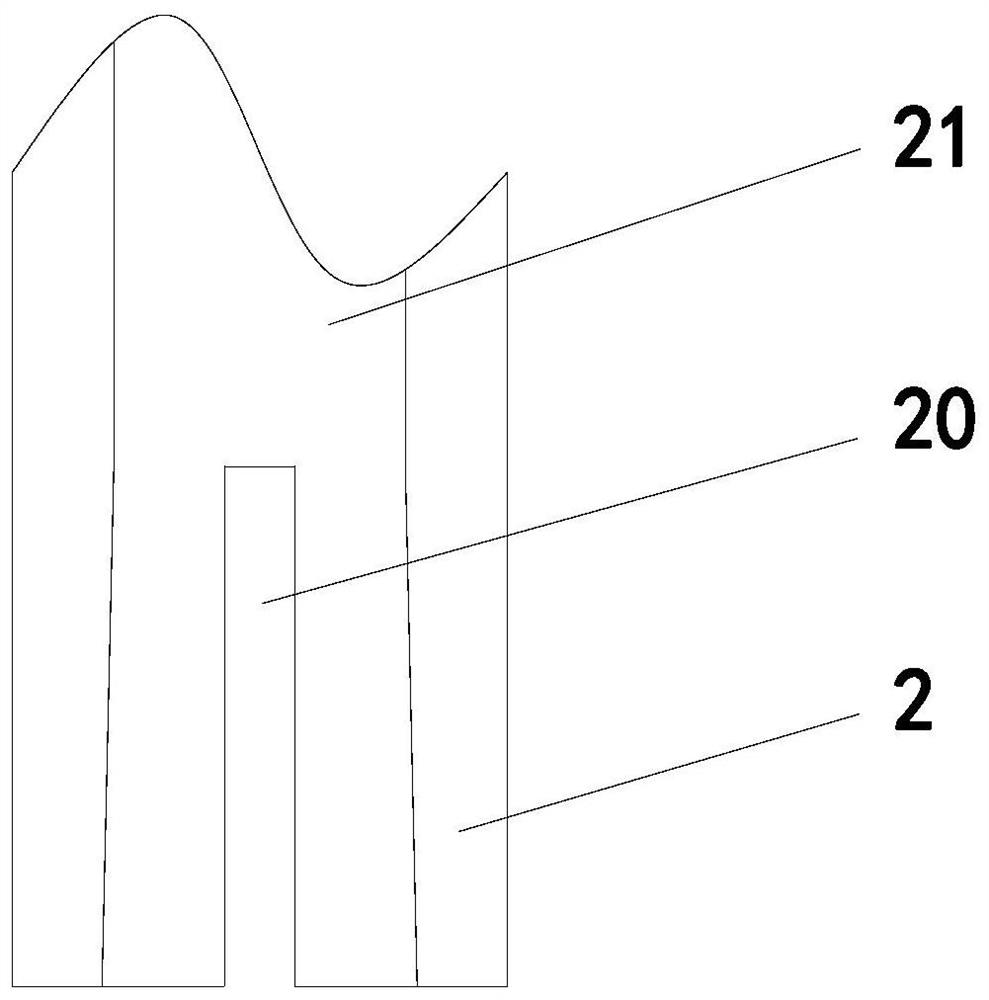

[0017] refer to figure 1 , figure 2 and image 3 , a water stop buckle for plugging leaks according to the present invention, comprising a fixing plate 1, a plastic cylinder 2, a rubber column 3, and a waterproof material 4, the fixing plate 1 is fixed on the wall, and the side of the fixing plate 1 close to the wall Waterproof material 4 is applied, and at least one plastic tube 2 is fixed on the wall side of the fixing plate 1, a through hole 21 is provided on the axis of the plastic tube 2, and several separation seams are provided on the side wall of the plastic tube 2 20. The separation seam 20 is opened at the end of the plastic tube 2, and each plastic tube 2 is equipped with a rubber column 3, the rubber column 3 is in the shape of a truncated cone, and the rubber column 3 is inserted into the plastic tube 2 from the end of the plastic tube 2, and the rubber column 3 The small-diameter end of the column 3 is close to the fixed plate 1. When the rubber column 3 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com