Building non-descending plate prefabricated squatting toilet

A prefabricated, toilet technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as the odor of water in the descending floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

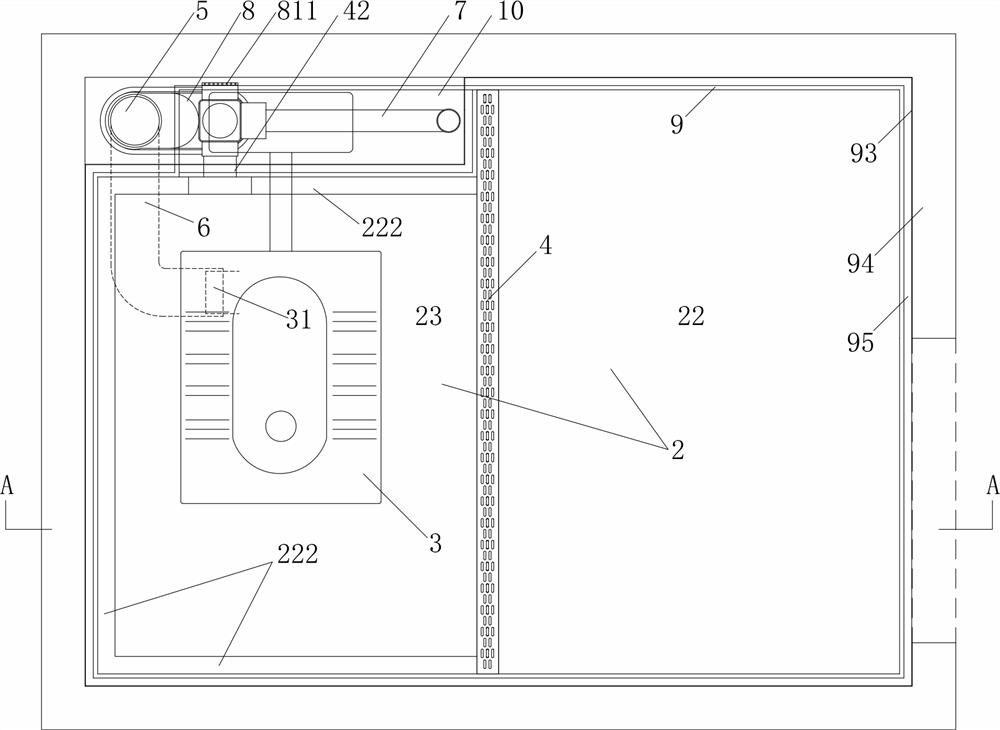

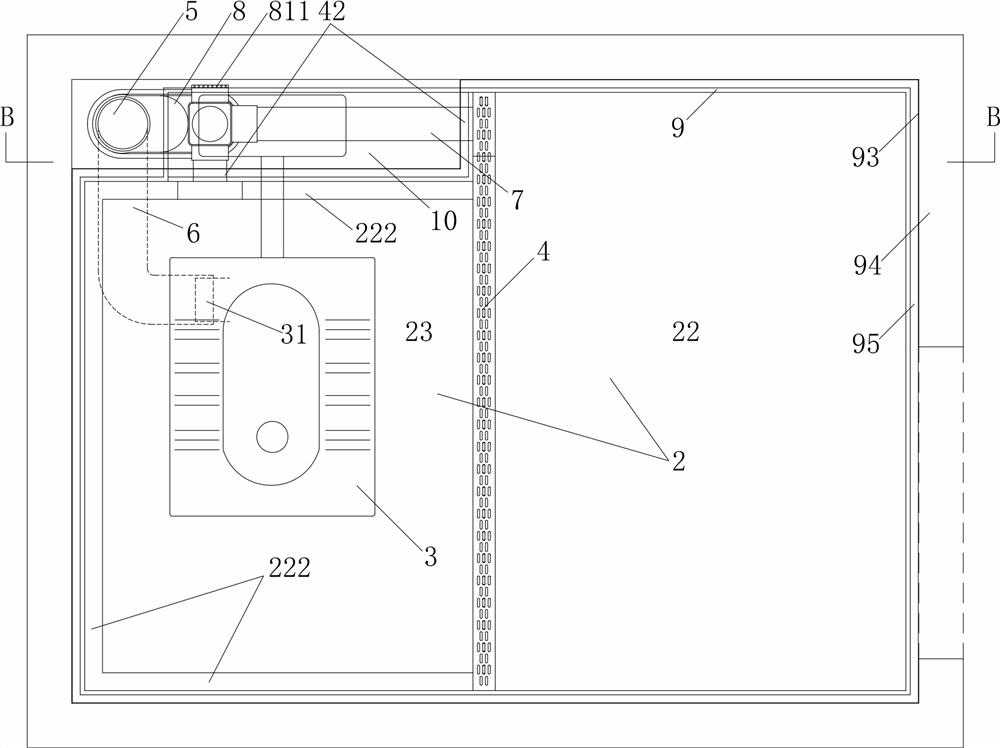

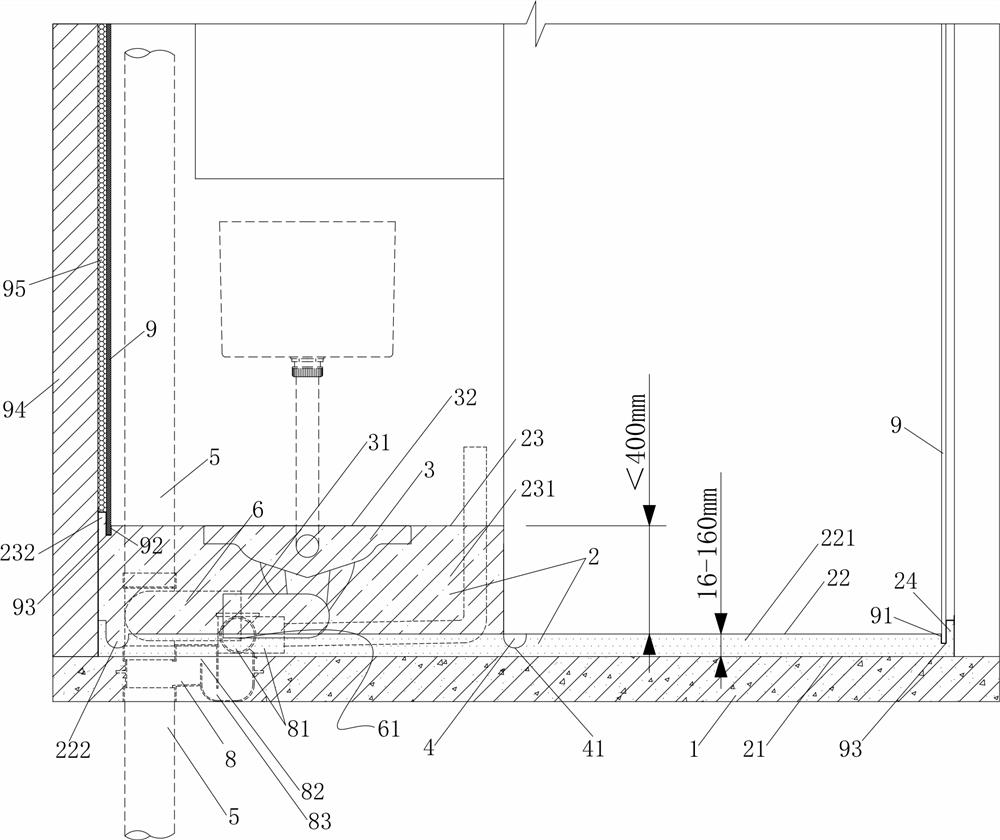

[0022] like Figure 1-5 As shown in the figure, a squatting toilet assembled with non-falling slabs is composed of a ground floor 1, a waterproof chassis 2, a squatting pan 3, a floor drain 4, a drainage standpipe 5, a sewage horizontal branch pipe 6, a waste water horizontal branch pipe 7, a drainage collector 8, The waterproof wall board 9 is composed of; preferably, the ground floor 1 is a 100mm thick reinforced concrete floor, the waterproof chassis 2 is made of high-strength, low-density materials, the squatting pan 3 is a side drainage ceramic sanitary product, and the floor drain 4 is integrated with the waterproof chassis 2 Formed strip drainage tank, drainage standpipe 5 and sewage horizontal branch pipe 6 are PVC-U drainage pipes of DN110mm, waste water horizontal branch pipe 7 is PVC-U drainage pipe of DN75mm, drainage collector 8 is made of PVC-U material, waterproof The wall board 9 is a rock board; the waterproof chassis 2 is located above the ground floor 1, the...

Embodiment 2

[0024] like figure 1 , 3 , 5, the low face 22 and the high face 23 of the waterproof chassis 2 are composed of two superimposed pieces, the high face block 231 and the low face block 221, the high face block 231 is above the low face block 221, and on the low face block 221 There is a leak-proof drainage groove 222, and the sewage discharge outlet 31 of the squatting pan 3 is on the inside of the leak-proof drainage groove 222, and is higher than the lowest point of the leak-proof drainage groove 222, and the leak-proof drainage groove 222 is connected with the floor drain 4, sharing the drainage outlet 42, All the other are with embodiment 1.

Embodiment 3

[0026] like figure 2 , 5 As shown, the low surface 22 and the high surface 23 of the waterproof chassis 2 are composed of two superimposed pieces, the high surface piece 231 and the low surface piece 221, the high surface piece 231 is above the low surface piece 221, and the low surface piece 221 has a waterproof Leakage drainage groove 222, the sewage discharge outlet 31 of squatting pan 3 is in the inner side of leakproof drainage groove 222, and is higher than the lowest point of leakproof drainage groove 222, and leakproof drainage groove 222 and floor drain are respectively provided with independent drainage outlet 42, the rest With embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com