Method for determining gold content in cyanided water sample

A determination method and technology of gold content, applied in the preparation of test samples, measuring devices, color/spectral characteristics measurement, etc., can solve the problems of many pretreatment processes and gold waste, and achieve the purpose of improving the vibration efficiency, improving the utilization rate, The effect of improving the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

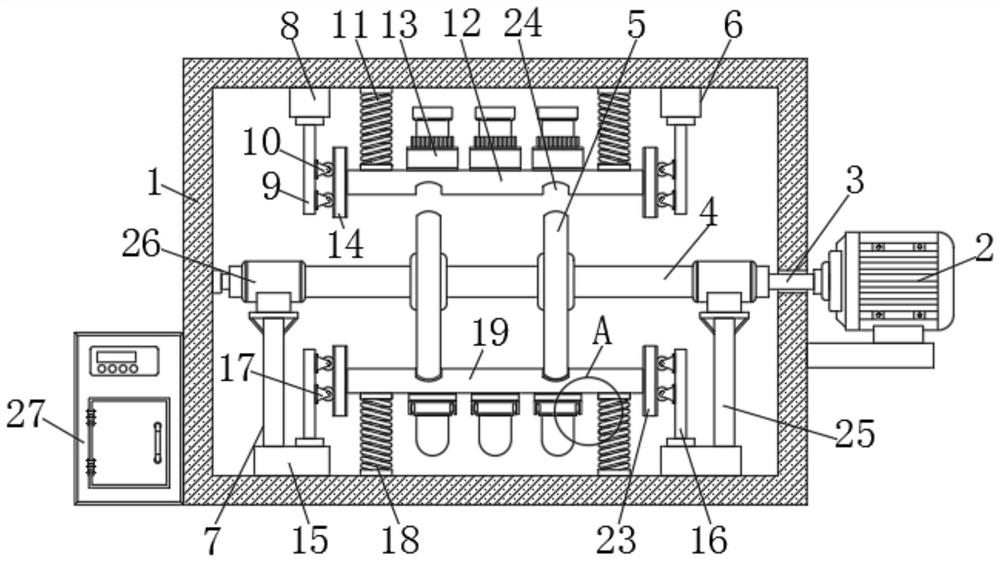

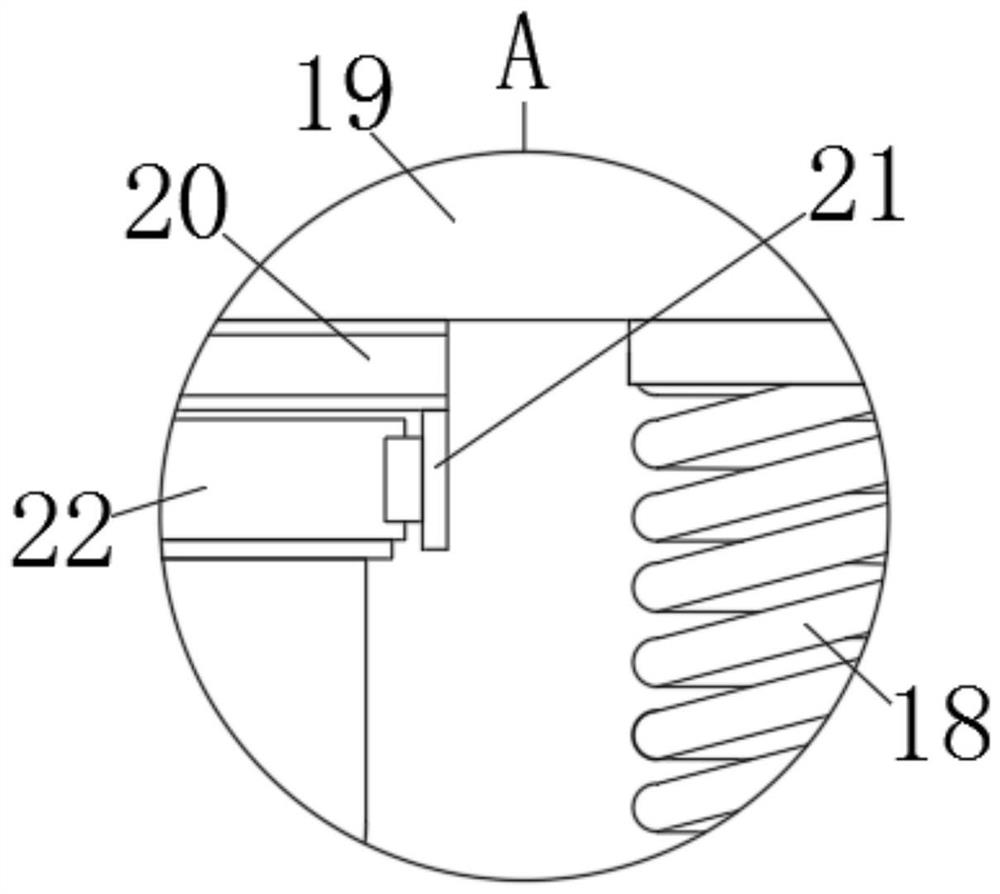

[0034] Such as Figure 1-2 Shown, a kind of assay method of gold content in the cyanide water sample comprises the following steps:

[0035] Step S1: Use a graduated cylinder to measure 100ml of cyanide water sample into a 250ml iodine bottle, add 2g of activated carbon powder into the iodine bottle, put the iodine bottle into a shaker for shaking, and divide the iodine bottle into two groups on average. One group of iodine bottles is fixed on the fixed seat, and another group of iodine bottles is fixed on the limit sleeve 22;

[0036]Step S2: start the driving motor 2 to drive the rotating rod 3 to rotate, and the cam 5 rotates synchronously with the rotating rod 3. When the protruding end of the cam 5 contacts the groove 24 of the first oscillating plate 12, it pushes the first oscillating plate 12 to move upward, and the cam 5 5 When separating from the groove 24 of the first oscillating plate 12, the first oscillating plate 12 quickly resets under the reaction force of th...

Embodiment 2

[0041] Such as Figure 1-2 Shown, a kind of assay method of gold content in the cyanide water sample comprises the following steps:

[0042] Step S1: Use a graduated cylinder to measure 100ml of cyanide water sample into a 250ml iodine bottle, add 2g of activated carbon powder into the iodine bottle, put the iodine bottle into a shaker for shaking, and divide the iodine bottle into two groups on average. One group of iodine bottles is fixed on the fixed seat, and another group of iodine bottles is fixed on the limit sleeve 22;

[0043] Step S2: start the driving motor 2 to drive the rotating rod 3 to rotate, and the cam 5 rotates synchronously with the rotating rod 3. When the protruding end of the cam 5 contacts the groove 24 of the first oscillating plate 12, it pushes the first oscillating plate 12 to move upward, and the cam 5 5 When separating from the groove 24 of the first oscillating plate 12, the first oscillating plate 12 quickly resets under the reaction force of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com