Multi-variety small-batch multi-target flexible job shop energy consumption optimization scheduling method

A flexible operation and optimal scheduling technology, applied in the energy industry, climate sustainability, control/regulation systems, etc., can solve the problems of energy consumption in the manufacturing workshop, complex production process, long working hours of a single process, etc., and reduce the energy consumption of the workshop. The effect of reducing energy consumption, saving the production cost of the enterprise, and shortening the time of job scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

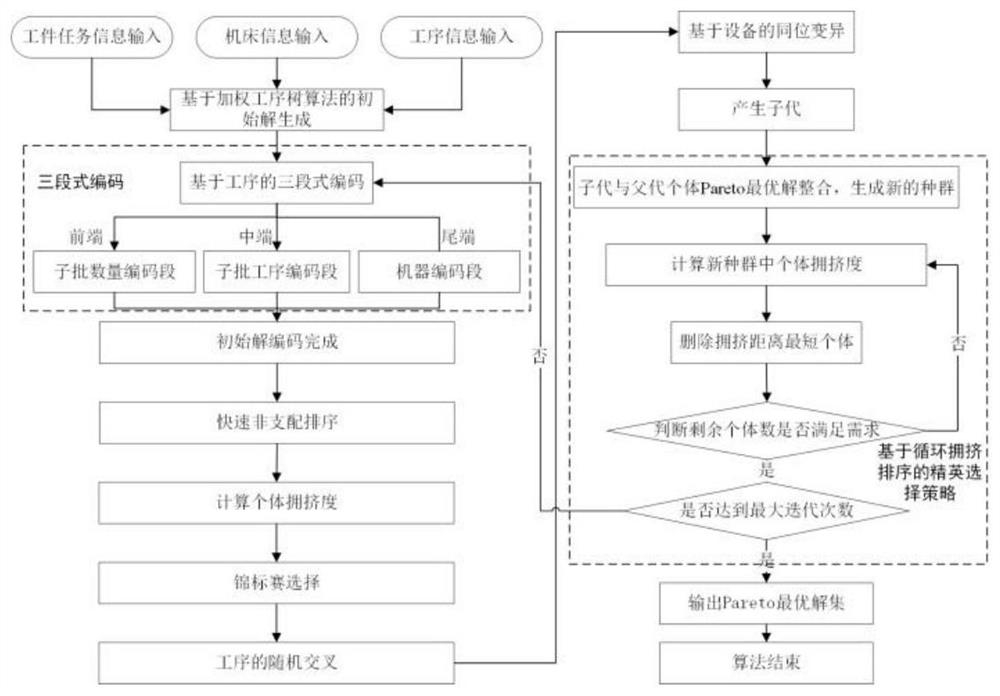

Method used

Image

Examples

Embodiment Construction

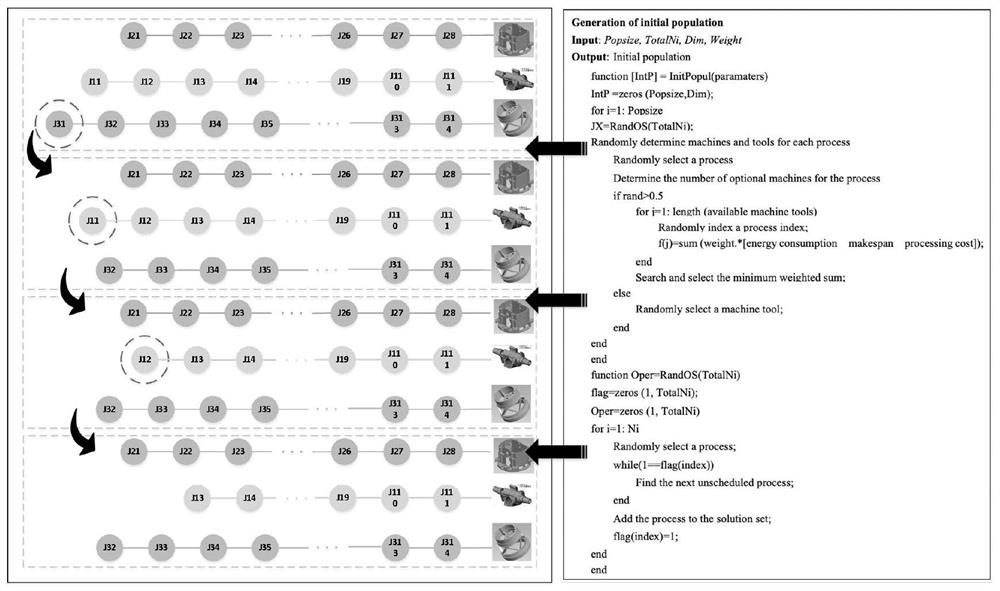

[0040] The present invention will be further described in detail below with reference to the accompanying drawings and the embodiments, but it should be understood that the embodiments are used to explain the present invention and are not intended to limit the present invention.

[0041] Build a mathematical model with the goal of the lowest total energy consumption, the shortest completion time, and the lowest processing cost.

[0042] Establish a mathematical model of equipment start-stop, processing, processing preparation, idle, and fixed energy consumption. The calculation formula is as follows:

[0043] E=E 启停 +E 加工 +E 准备 +E 空闲 +E 固定

[0044] Establish a mathematical model of completion time for batch scheduling of multi-variety and small-batch job shops. The calculation formula is as follows:

[0045]

[0046] Establish a mathematical model of the machining process cost, and calculate the formula:

[0047]

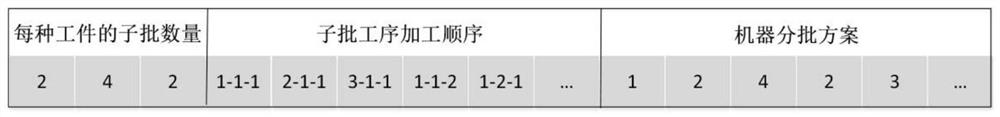

[0048] The equal batch method is adopted, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap