AGV scheduling method and device

A scheduling method and target location technology, applied in the field of electronic information, to achieve the effect of low transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

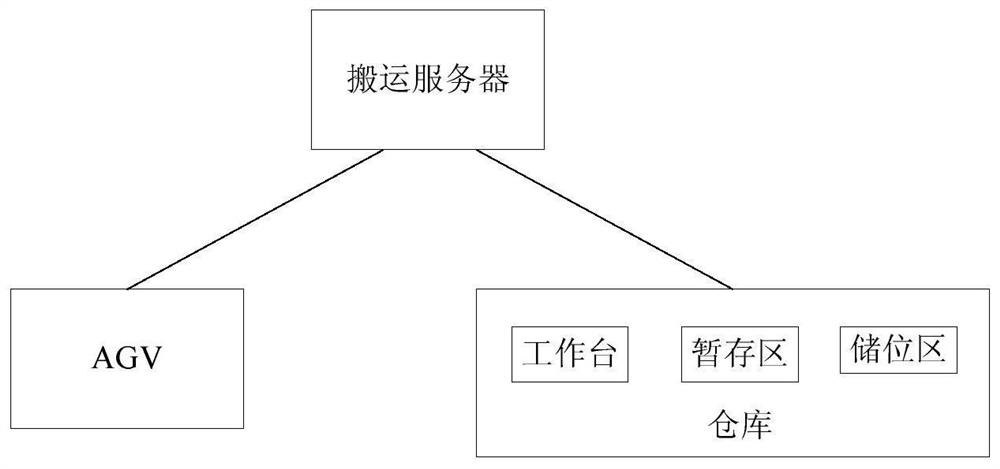

[0029] see figure 1 , figure 1 is a schematic diagram of the architecture of the mobile carrier handling system according to the embodiment of the present invention, such as figure 1 As shown, the mobile carrier handling system includes: a handling server, an AGV, and a warehouse; wherein, the warehouse includes a workbench, a temporary storage area, and a storage area.

[0030] In the embodiment of the present invention, the transport process of the movable carrier is divided into two transport processes from the storage area to the workbench and from the workbench to the storage area. Among them, for the transportation process of the movable carrier from the storage area to the workbench, the multiple temporary storage areas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com