Wet dust removal and purification system

A purification system, wet dust removal technology, applied in chemical instruments and methods, multi-stage water treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of low dust content in the wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

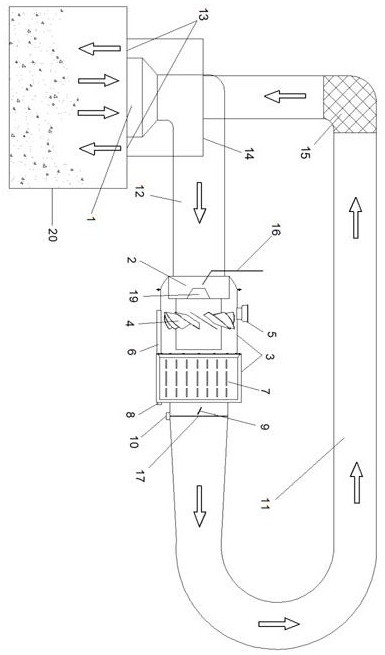

[0014] An example of the present invention will be further described below in conjunction with accompanying drawing:

[0015] The invention provides a wet dust removal and purification system, which is used for wet dust removal, purification and dehydration, and is installed in a horizontal arrangement.

[0016] The mouth of the water inlet is obliquely aligned with the center of the rotating disk, and the distance is 2-10cm.

[0017] The distance between both sides of the air return hood 14 and the dust collection hood 1 is 20-35cm, the diameter of the return air hood 14 is 160-270cm, and the diameter of the dust collection hood 1 is 120-200cm.

[0018] A wet dust removal and purification system, including a dust collection cover, an impeller, a dust collector casing, guide vanes, a motor, a first-stage dehydration plate, a second-stage dewatering grid, a drain port, a baffle plate, a third-stage dehydration port, and a return Air cylinder, air inlet cylinder, air curtain, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com