Environment-friendly dust removal treatment equipment

A processing equipment and environmental protection technology, applied in the field of environmental protection dust removal processing equipment, can solve the problems of performance discount, affecting travel and physical health, and reducing the purification effect, and achieve the effect of solving the hygienic working environment and preventing smog.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

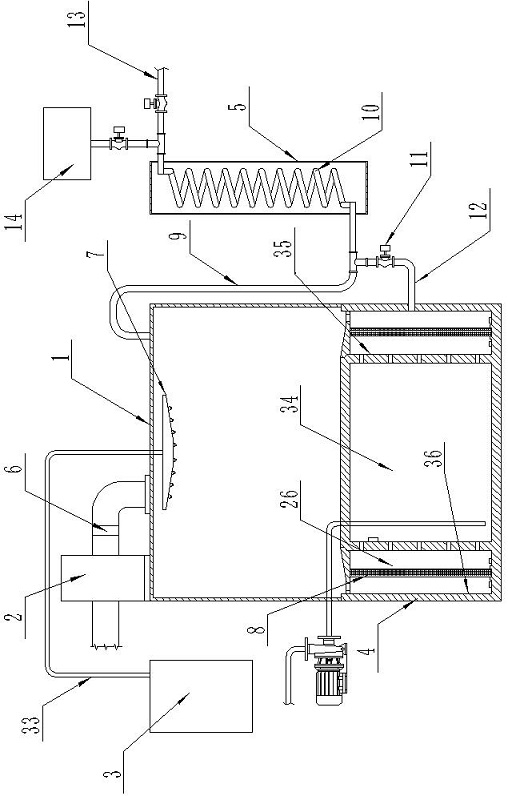

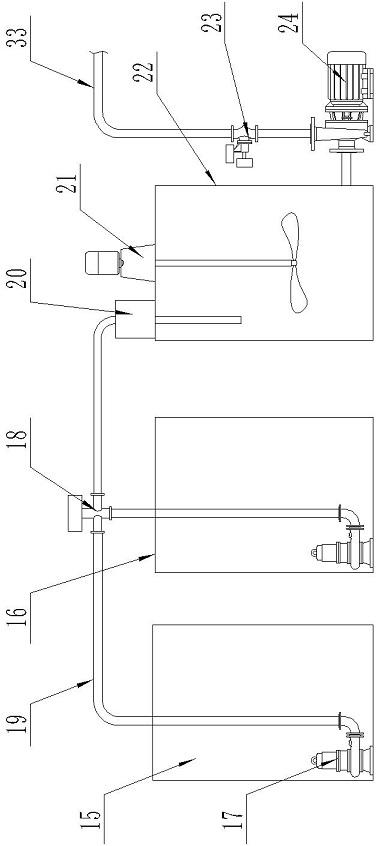

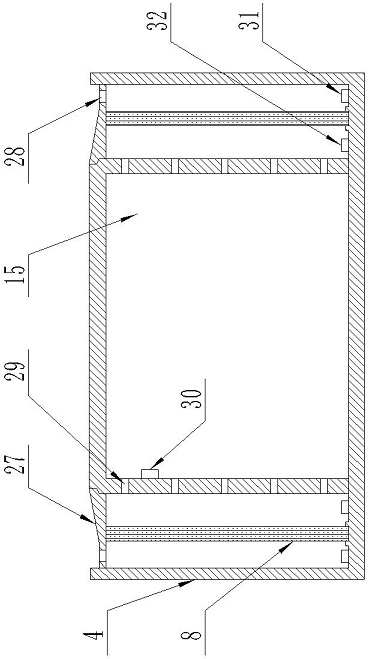

[0024] Such as Figure 1-5 As shown, the environmental protection dust removal treatment equipment includes a spray box 1, a negative pressure fan 2, a spray system, and a drying device 5. The spray box 1 is connected with a negative pressure fan for introducing gas into the spray box 1 through a pipeline. 2. A spray system is installed in the spray box 1. The steam-water mixture sprayed out by the spray system fully contacts with the gas, so that the water vapor and the particulate matter inside the gas fall off after being adsorbed. The bottom of the spray box 1 is installed for filtering dust and sewage. The filter tank 4, the sewage formed by the gas-water mixture a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com