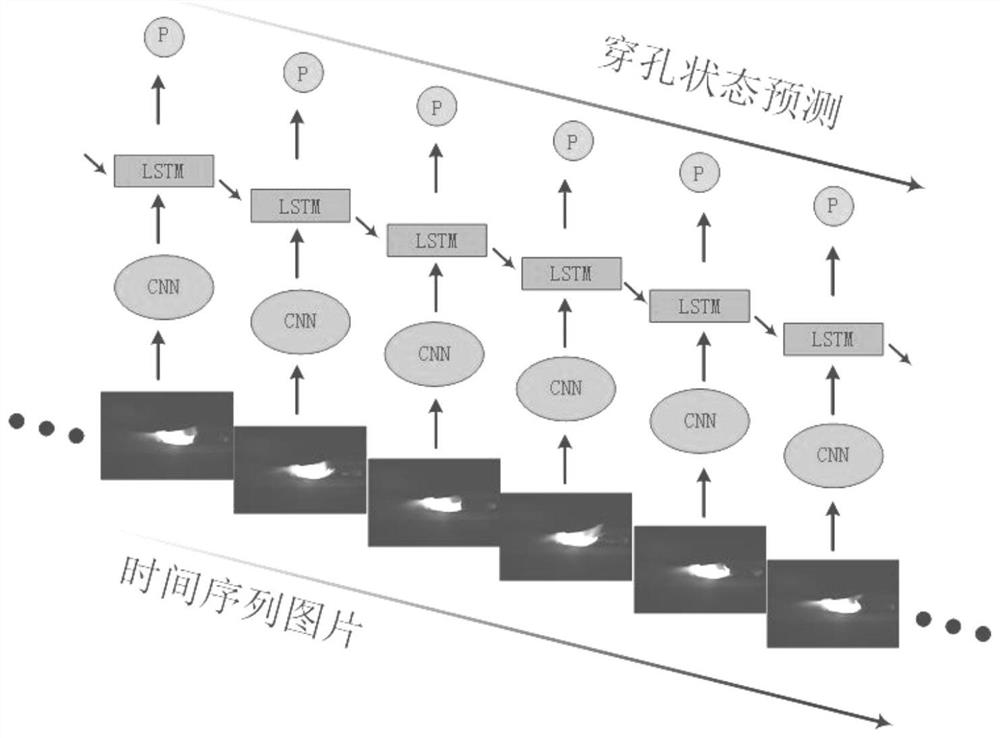

A method for predicting molten pool state in perforated plasma arc welding based on deep learning algorithm

A deep learning, plasma arc technology, applied in plasma welding equipment, welding equipment, computers, etc., can solve the problem of low generalization ability of training models, reduce data processing time and memory running space, improve efficiency, and facilitate collection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for predicting the molten pool state of perforated plasma arc welding based on a deep learning algorithm, including a training process and a testing process, the steps are as follows:

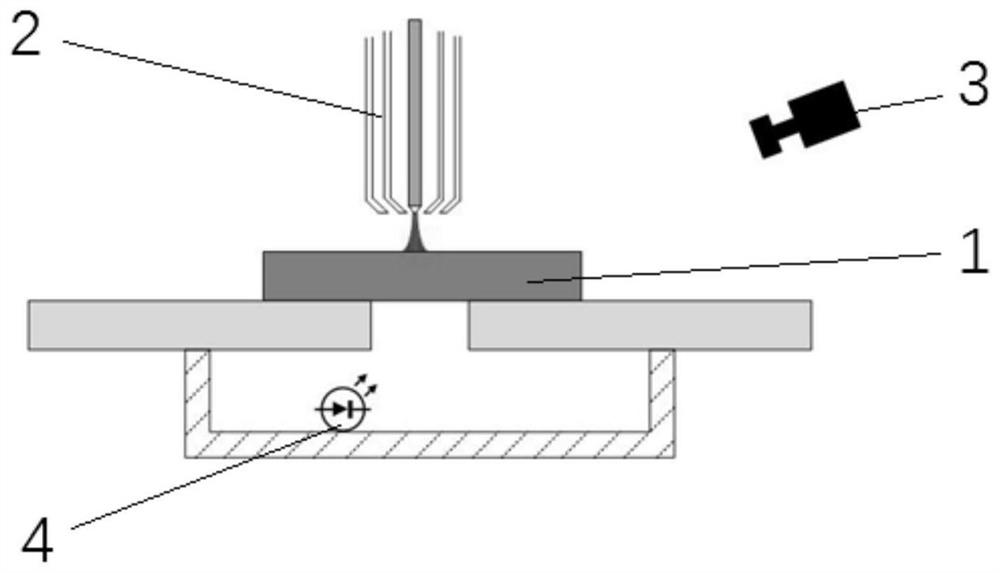

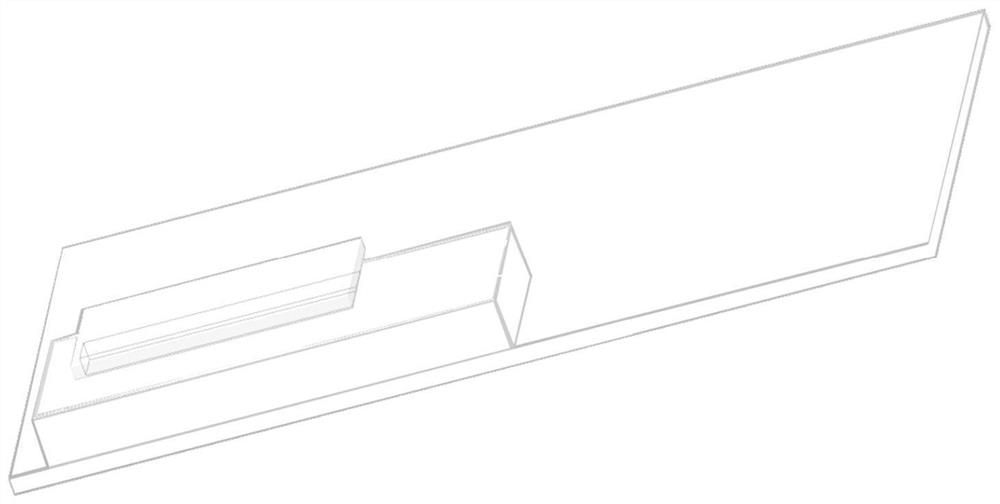

[0042] 1. Build an experimental platform; the experimental platform includes workpieces to be welded, such asfigure 1 , 2 As shown, a welding torch and a CCD camera are installed on one side of the workpiece to be welded. The CCD camera is used to collect the information of the front molten pool. A lot of molten pool information such as reflected arc light, pinhole information, and shape of molten pool metal. Because the distance between the plasma arc welding torch and the welding material is too close, it is not conducive to the installation of the CCD camera. The CCD camera is installed in the vertical direction of the welding direction and forms a certain angle with the horizontal direction. On the other side of the workpiece to be welded, directly below the welding torch, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com