Positioning device for copper gasket machining

A technology for positioning devices and copper gaskets, applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting the quality of finished products, copper gaskets, uneven force, deformation, etc., to achieve convenient fixing and increase The effect of applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

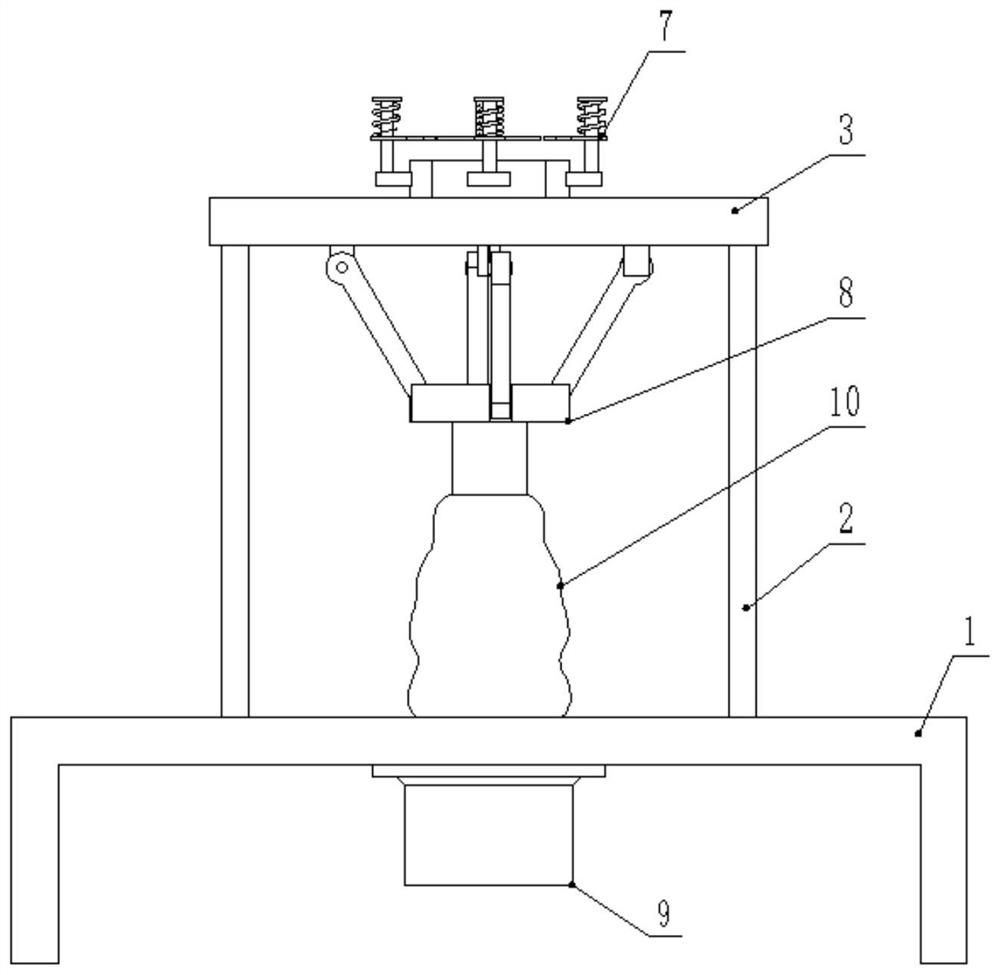

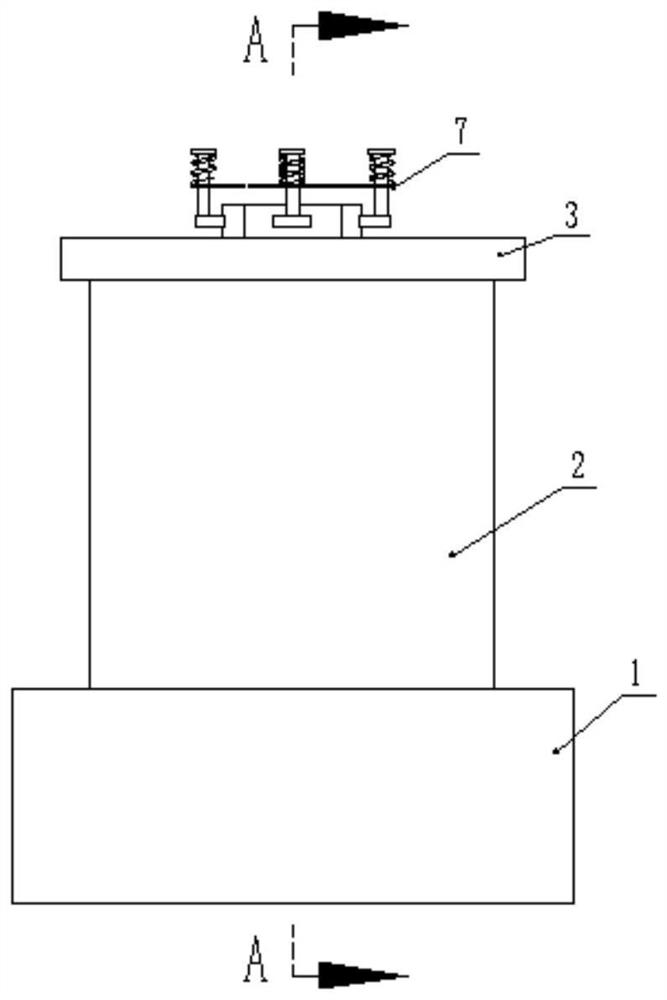

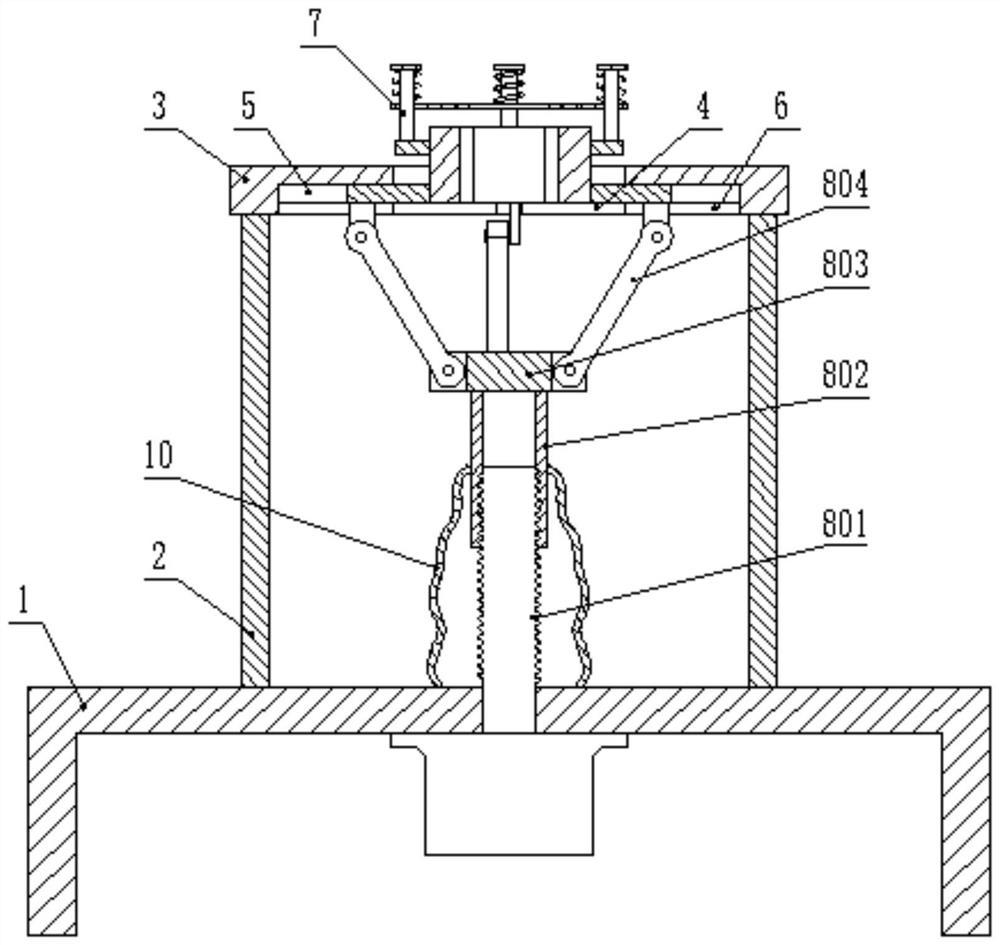

[0026] Example 1: Please refer to figure 1 , 2 And 5, a copper gasket processing and positioning device, including a base 1, a support plate 2 is fixedly connected to the base 1, and the support plate 2 is symmetrically arranged on the left and right, and the upper end of the support plate 2 is fixedly connected to a platform plate 3, and the platform plate 3 There is a through hole 4 in the middle, and several sinking grooves 5 evenly distributed on the circumference are opened on the side wall of the through hole 4, and a through groove 6 is opened on the lower surface of the platform plate 3, and the sinking groove 5 passes through the through hole 4 on the platform plate 3 A workpiece fixing mechanism 7 is slidingly connected, and a control mechanism 8 is arranged between the support plates 2 above the base 1;

[0027] see image 3 , the bottom of the base 1 is fixedly connected with a motor 9, and the output end of the motor 9 is connected with the control mechanism 8; ...

Embodiment 2

[0037] Embodiment 2: This embodiment makes supplementary explanations based on the previous implementation: please refer to figure 1 , 2 And 5, a copper gasket processing and positioning device, including a base 1, a support plate 2 is fixedly connected to the base 1, and the support plate 2 is symmetrically arranged on the left and right, and the upper end of the support plate 2 is fixedly connected to a platform plate 3, and the platform plate 3 There is a through hole 4 in the middle, and several sinking grooves 5 evenly distributed on the circumference are opened on the side wall of the through hole 4, and a through groove 6 is opened on the lower surface of the platform plate 3, and the sinking groove 5 passes through the through hole 4 on the platform plate 3 A workpiece fixing mechanism 7 is slidingly connected, and a control mechanism 8 is arranged between the support plates 2 above the base 1;

[0038] see image 3 , the bottom of the base 1 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com