Patents

Literature

34results about How to "Avoid positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

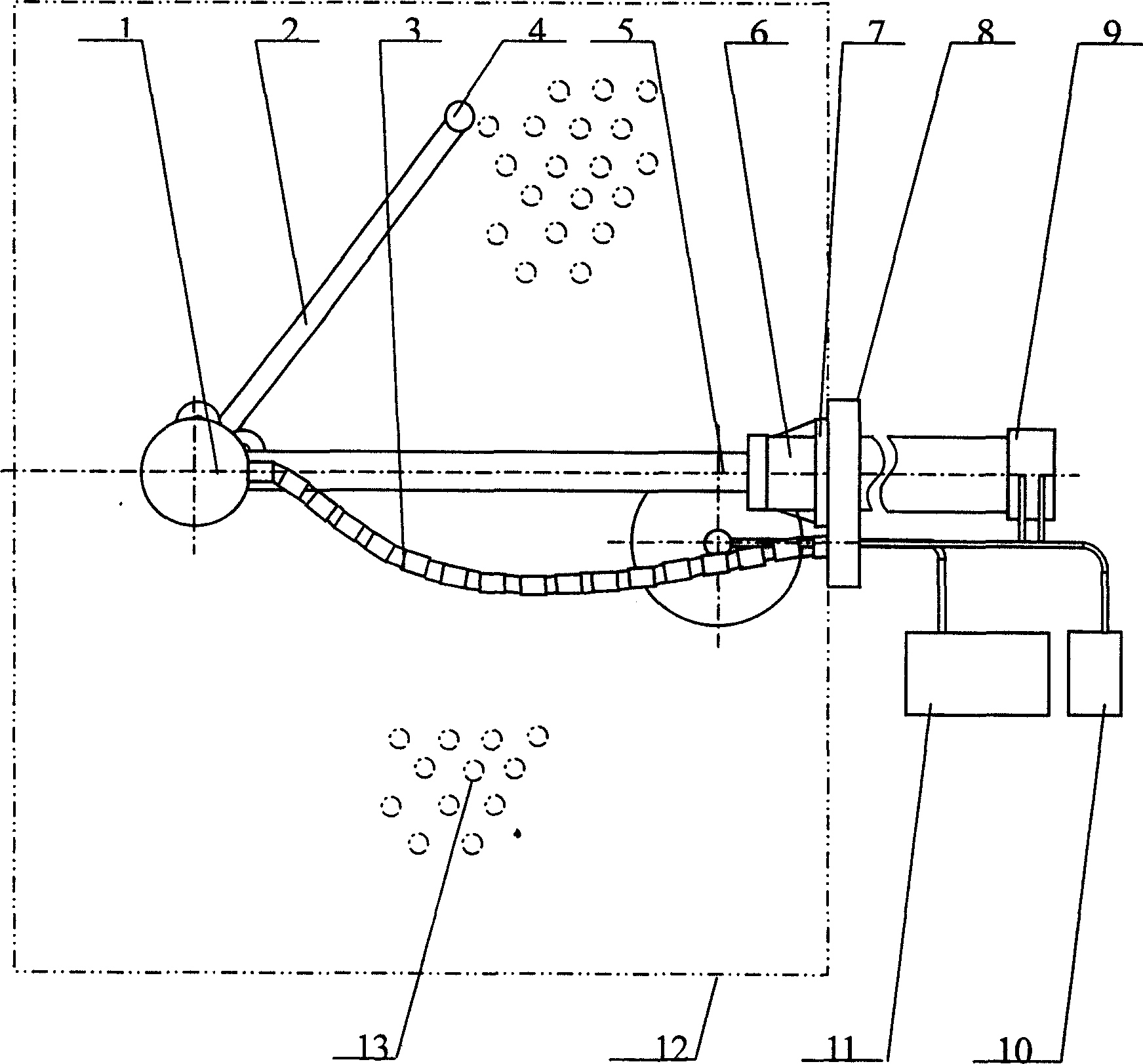

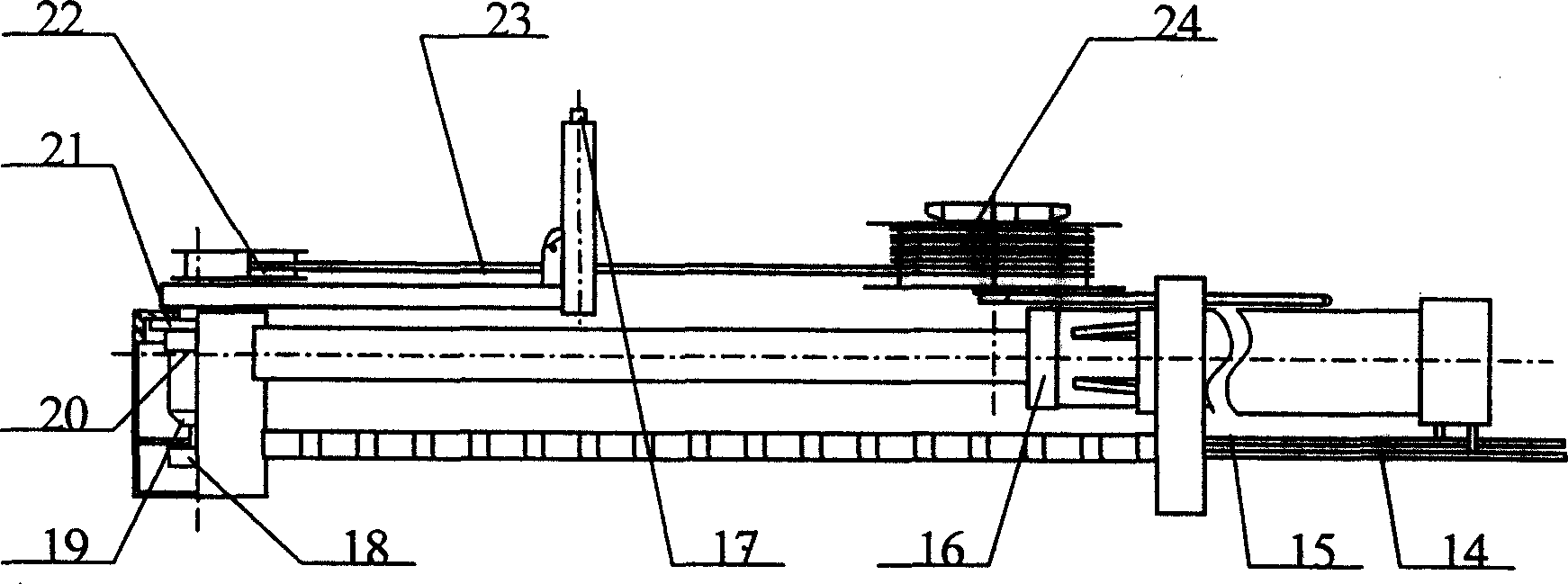

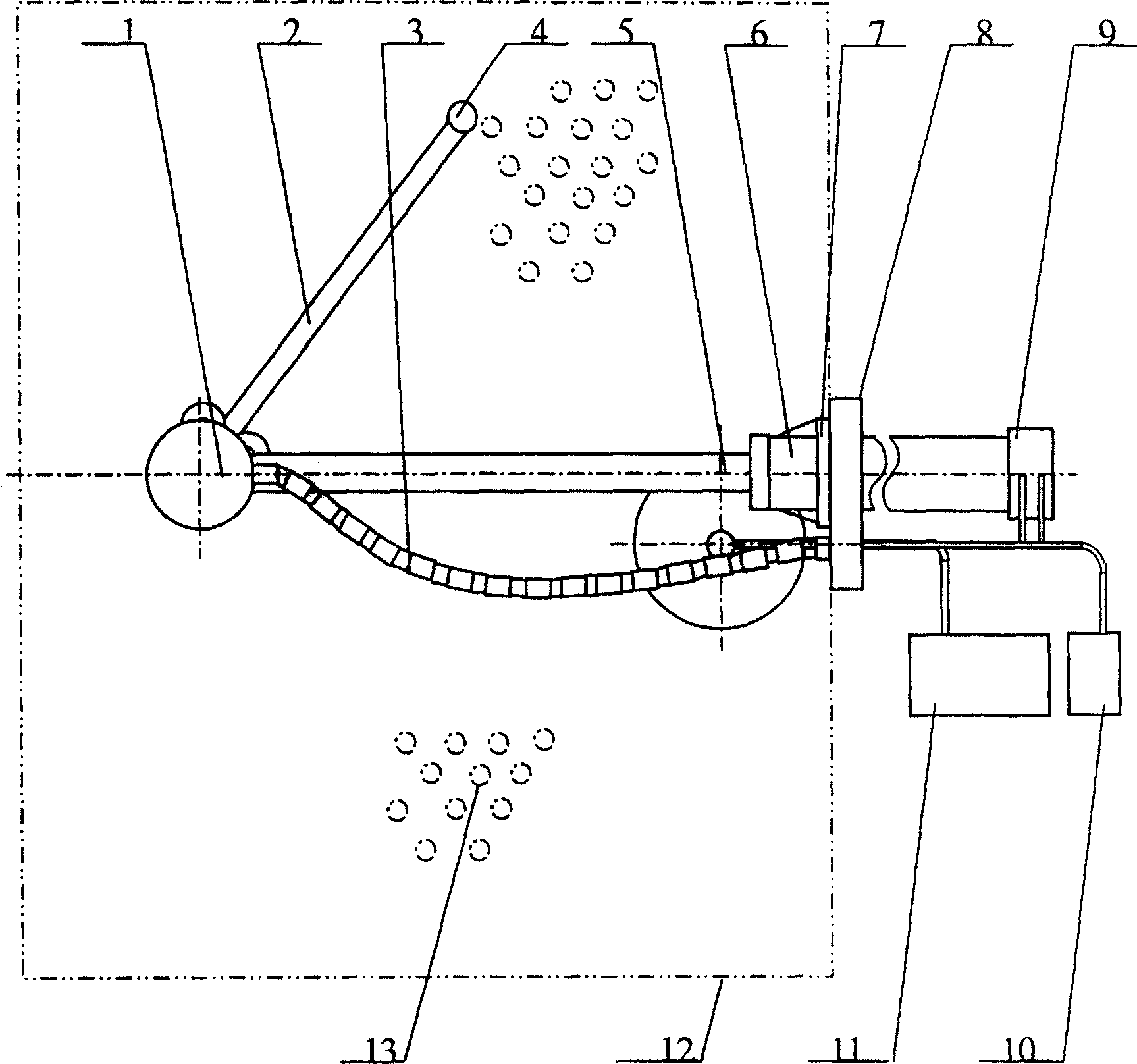

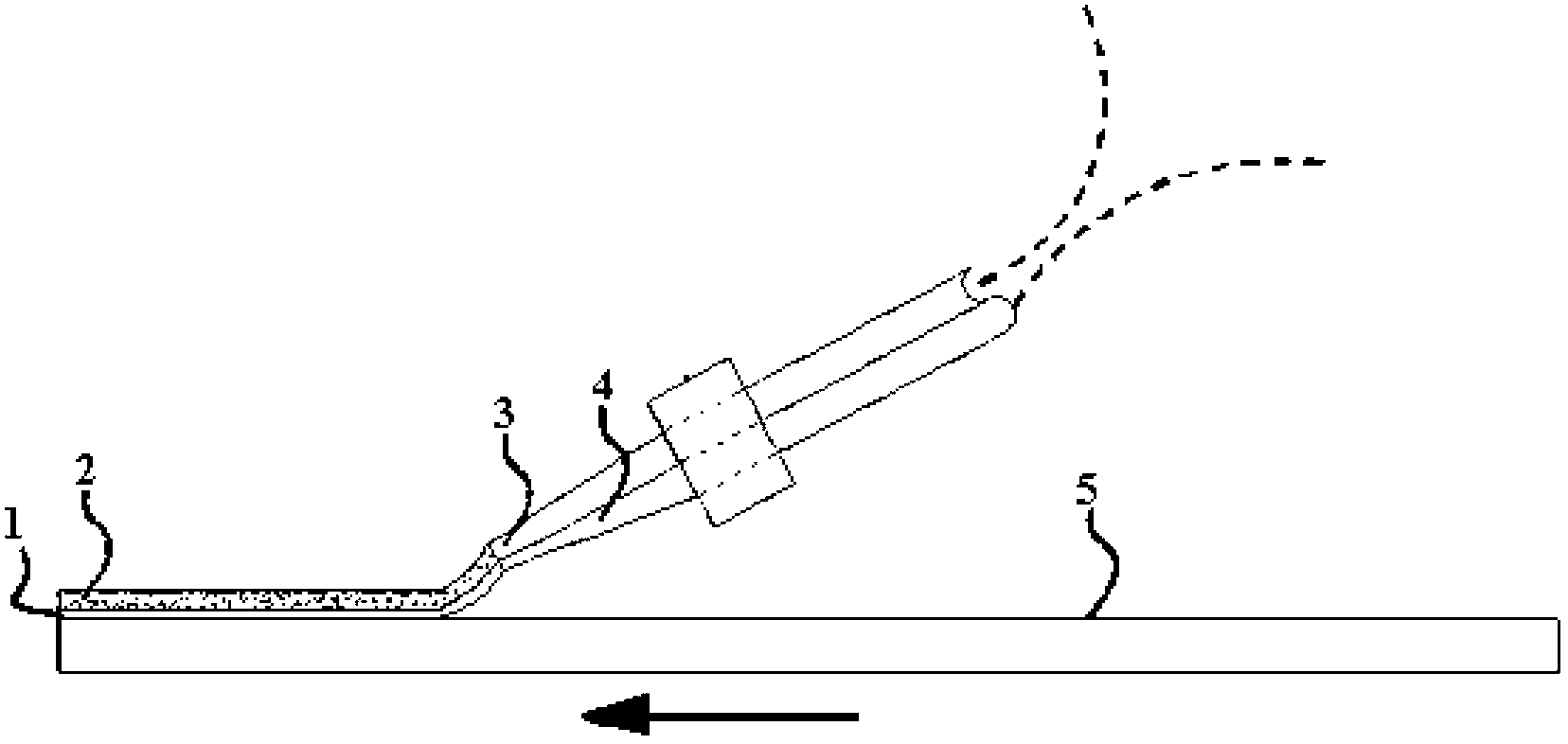

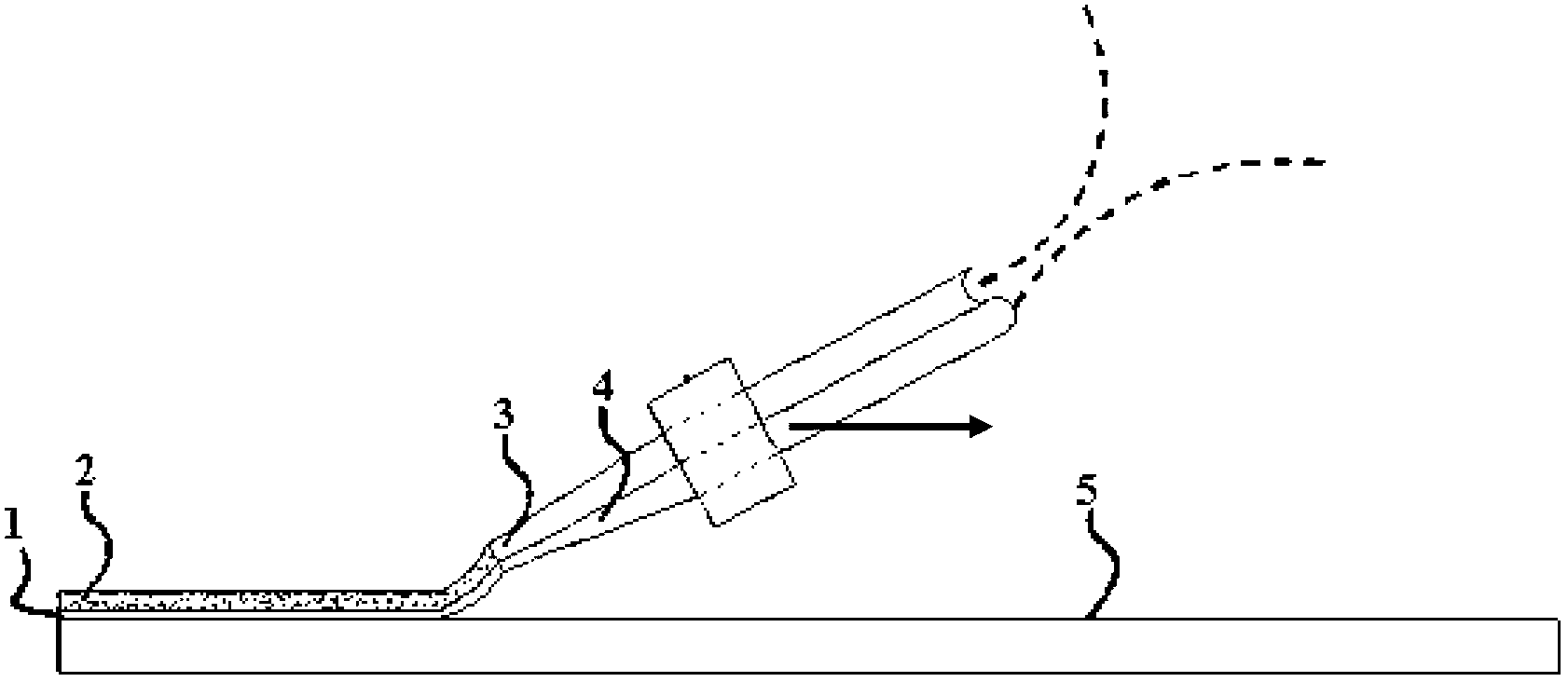

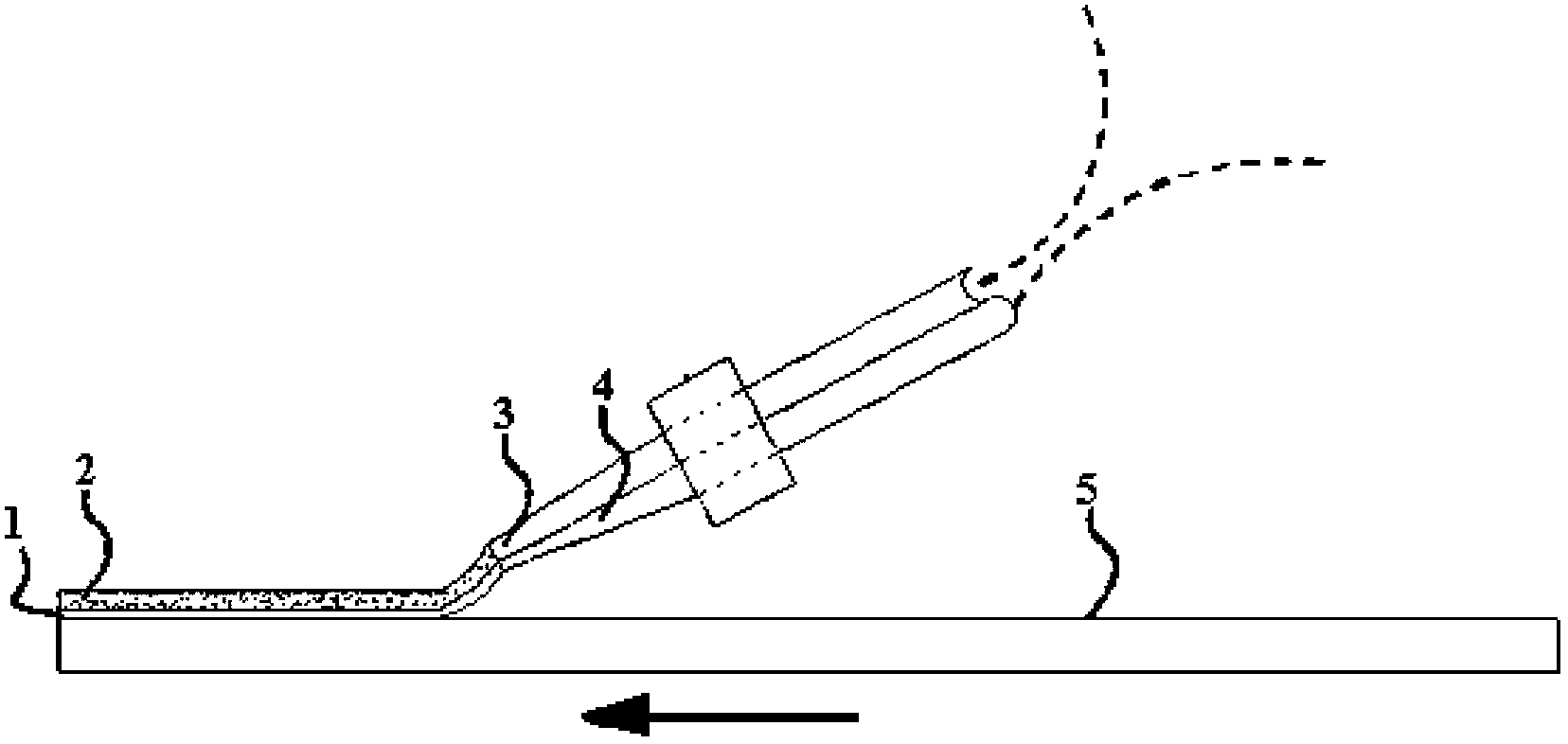

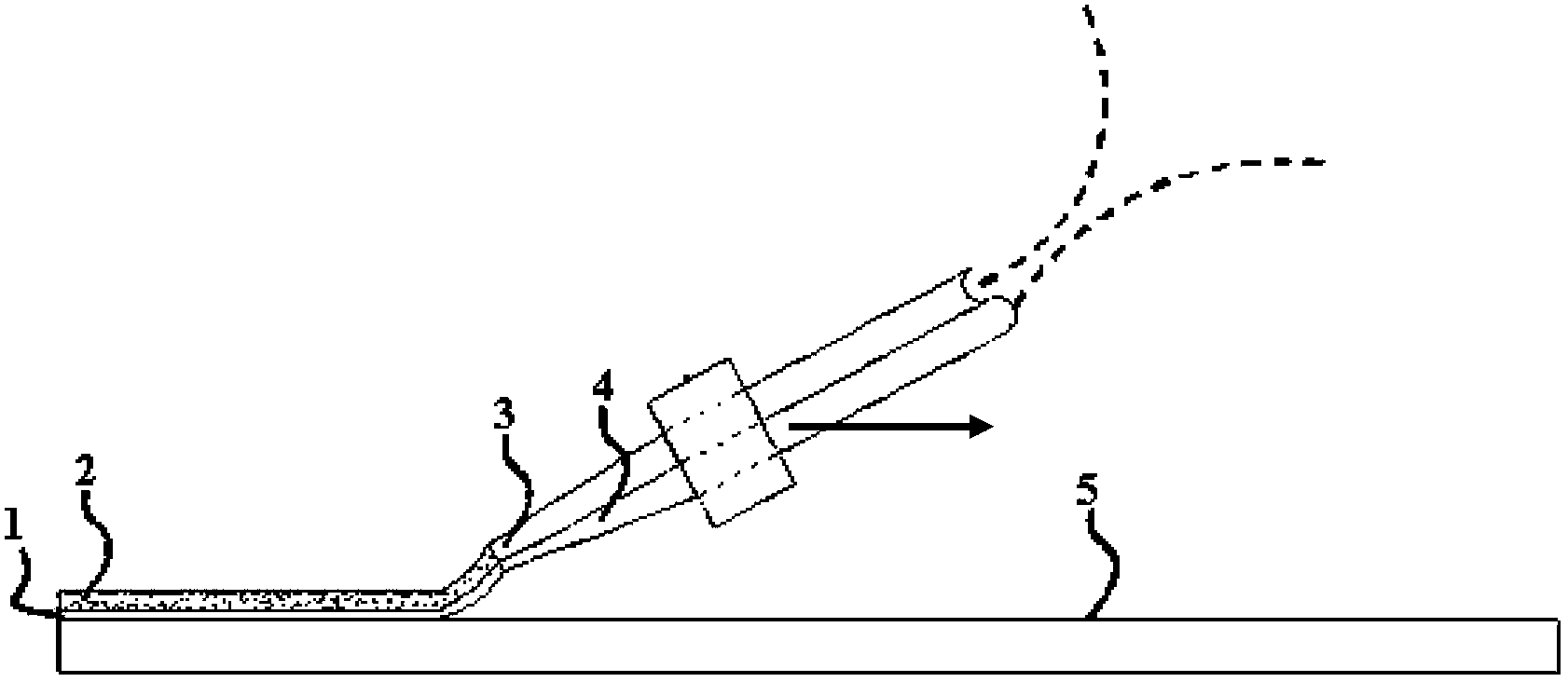

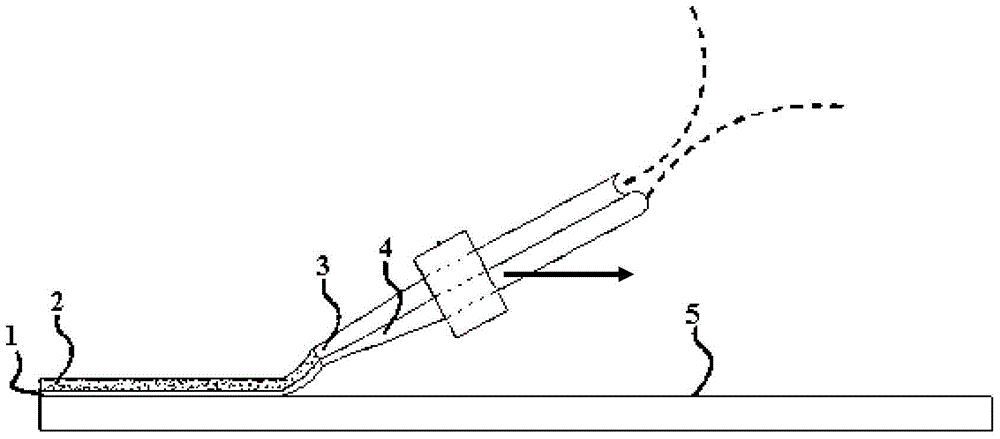

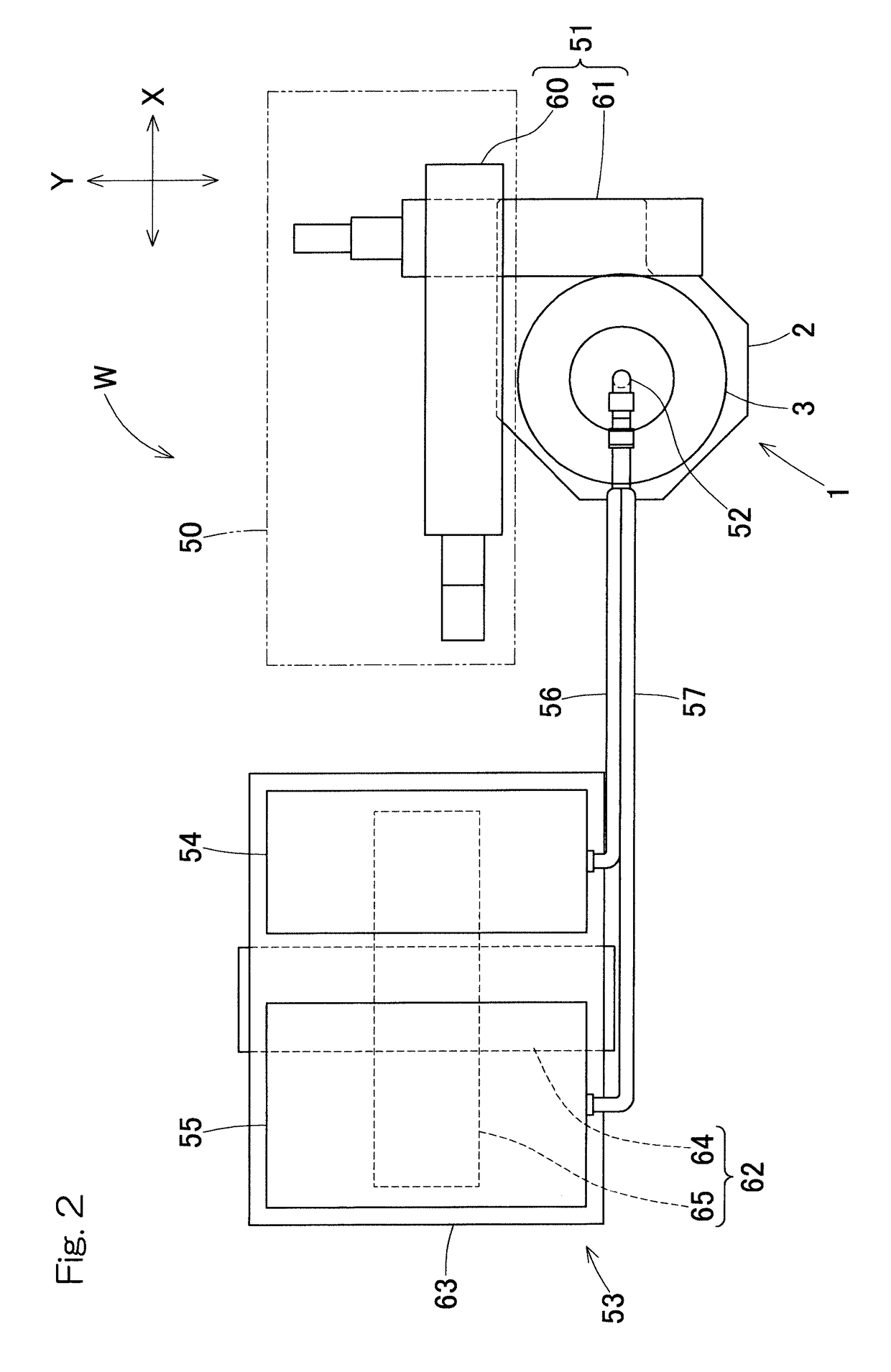

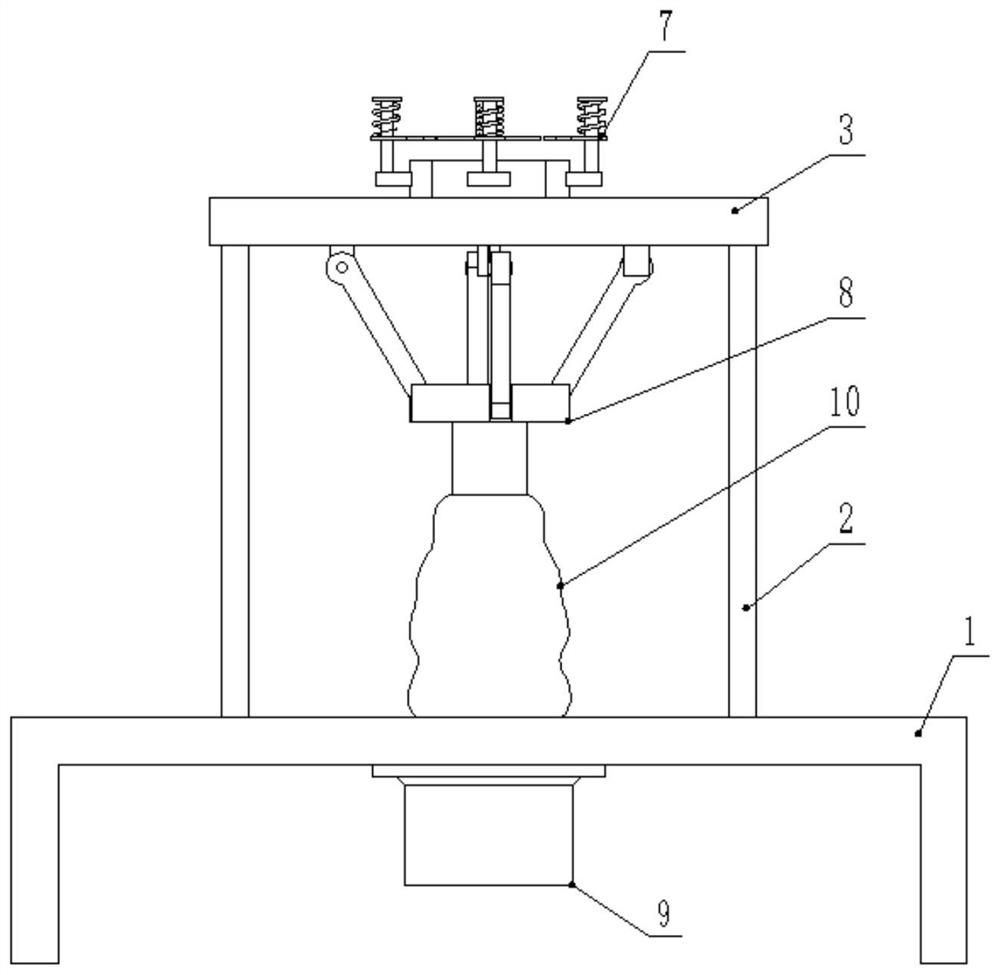

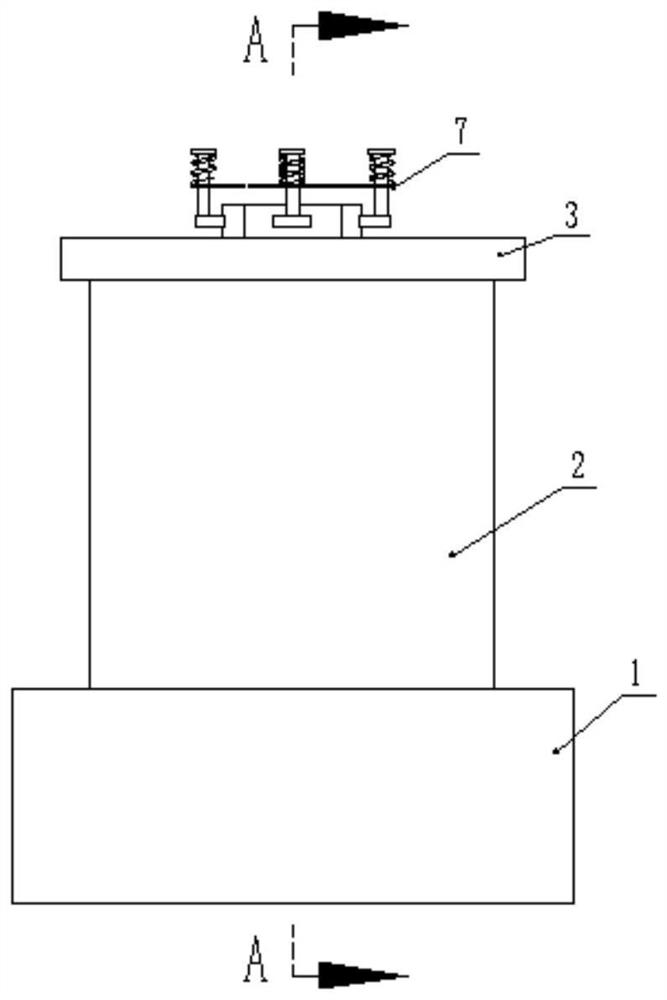

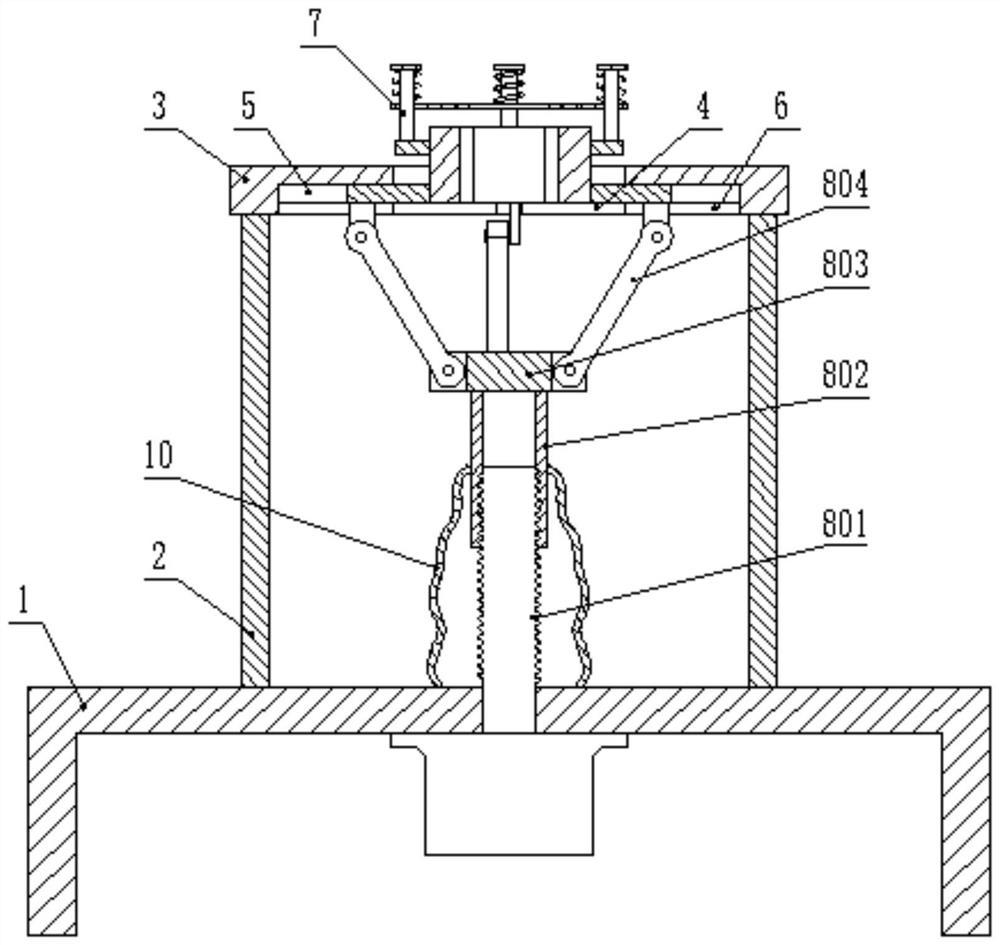

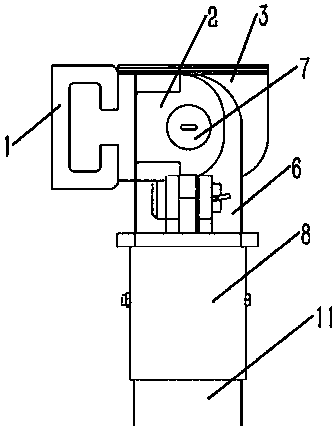

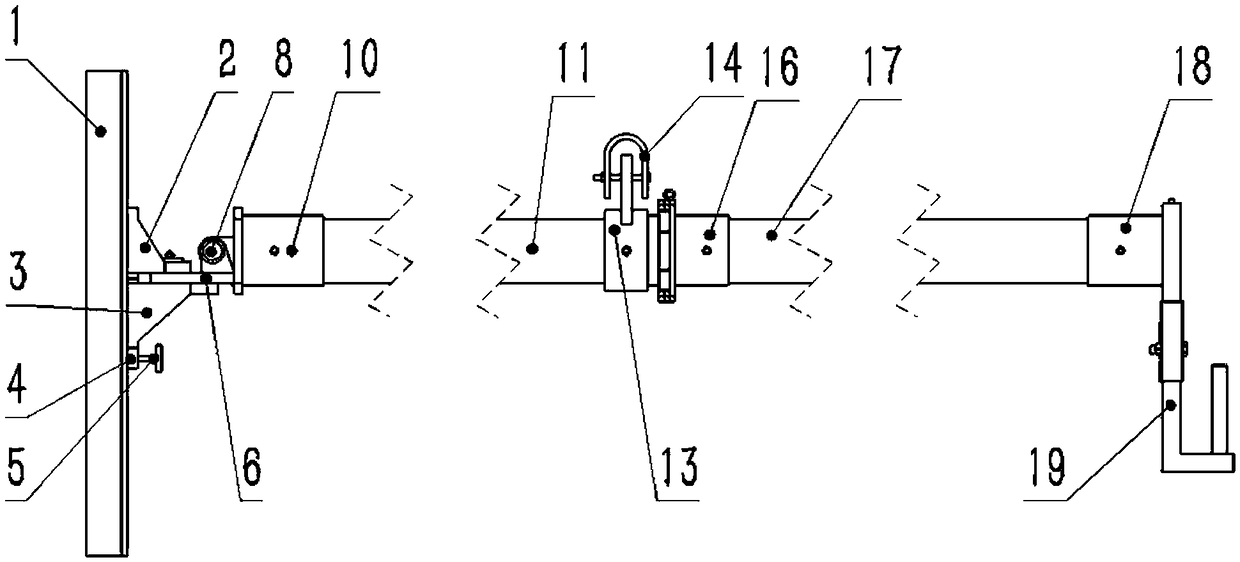

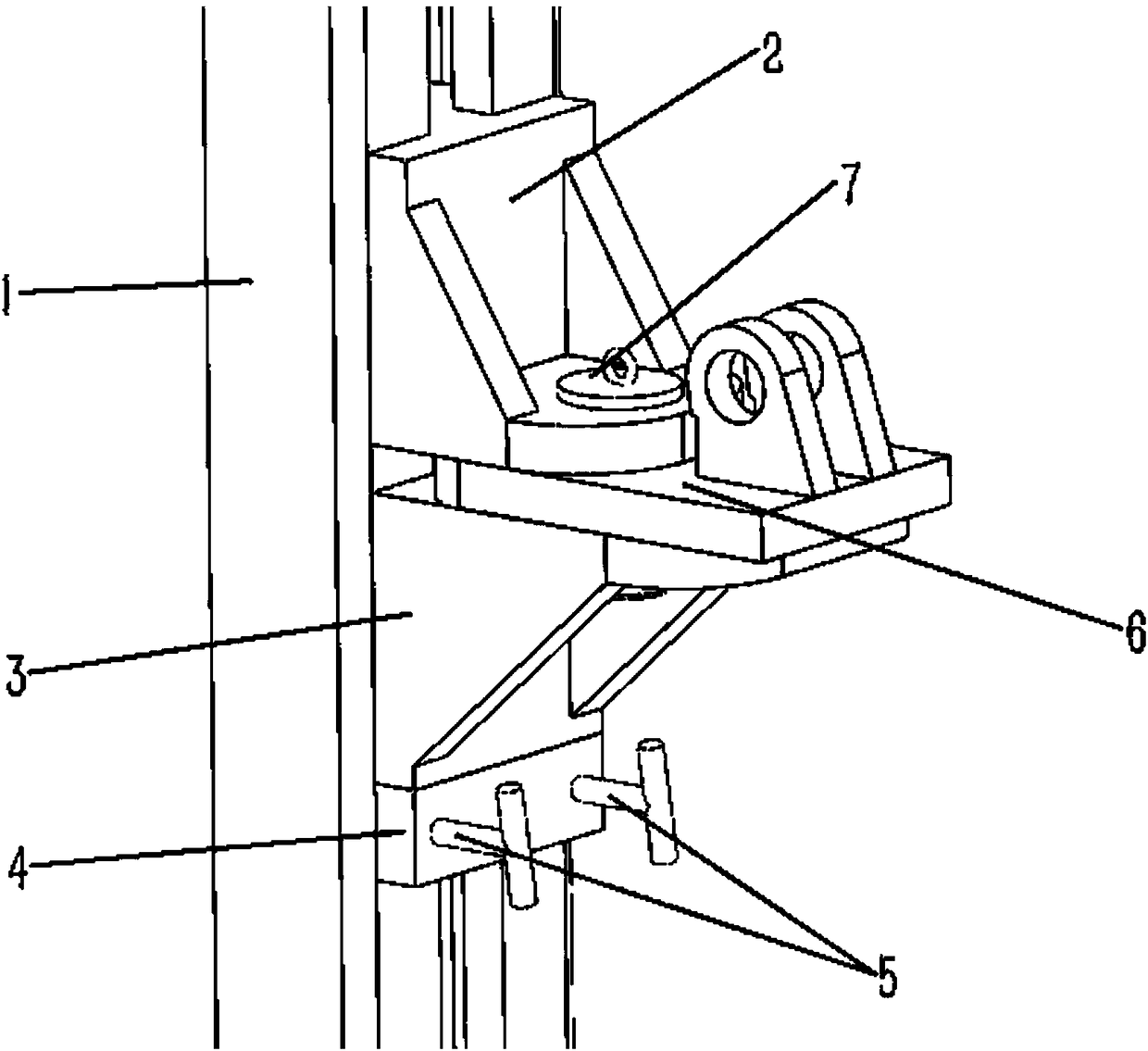

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN1664486AImprove operational efficiencyMaximize coverage areaRotary device cleaningNon-rotary device cleaningDevice formHigh pressure water

The invention relates to an electric power plant condenser high pressure water shooting flow online washing robot technology that cleans the electric power plant condenser by high pressure water shooting flow. Setting the mechanism arm locating device and high pressure soft tube into the condenser by using the combination method and install structure of locating mechanism arm orientation device formed by extending mechanism arm and rotating mechanism arm, high pressure soft tube manage device, and high pressure spray head control device, locates the spray head on the rotating mechanism arm by computer control system, sends to the inner of the condenser copper pipe, and cleans the dirt in the inner of the condenser copper pipe by high pressure water shooting flow. The generating set needs not stop while cleaning. The invention has advantage of simple structure, no pollution and high reliability.

Owner:CHINA UNIV OF MINING & TECH

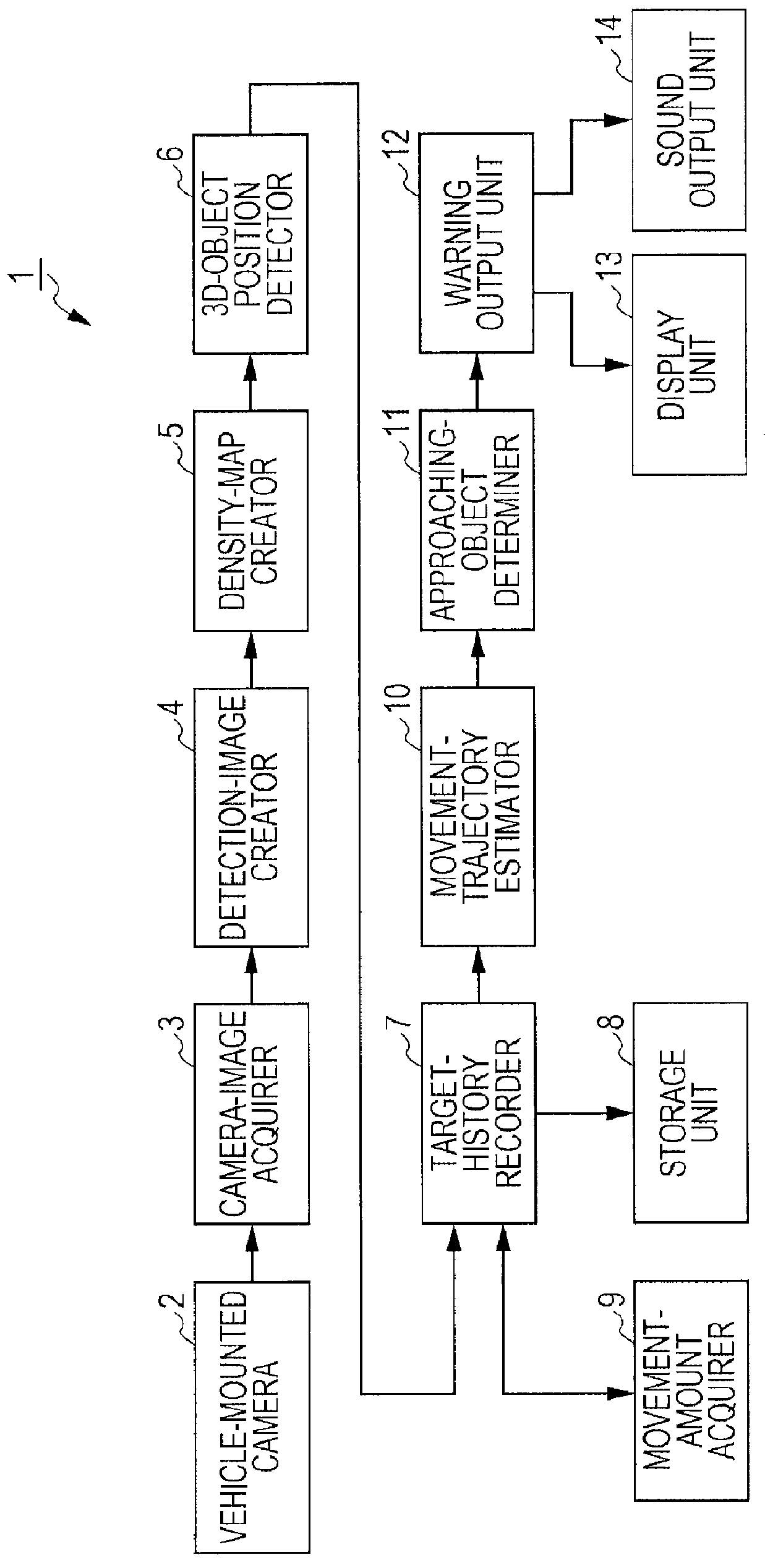

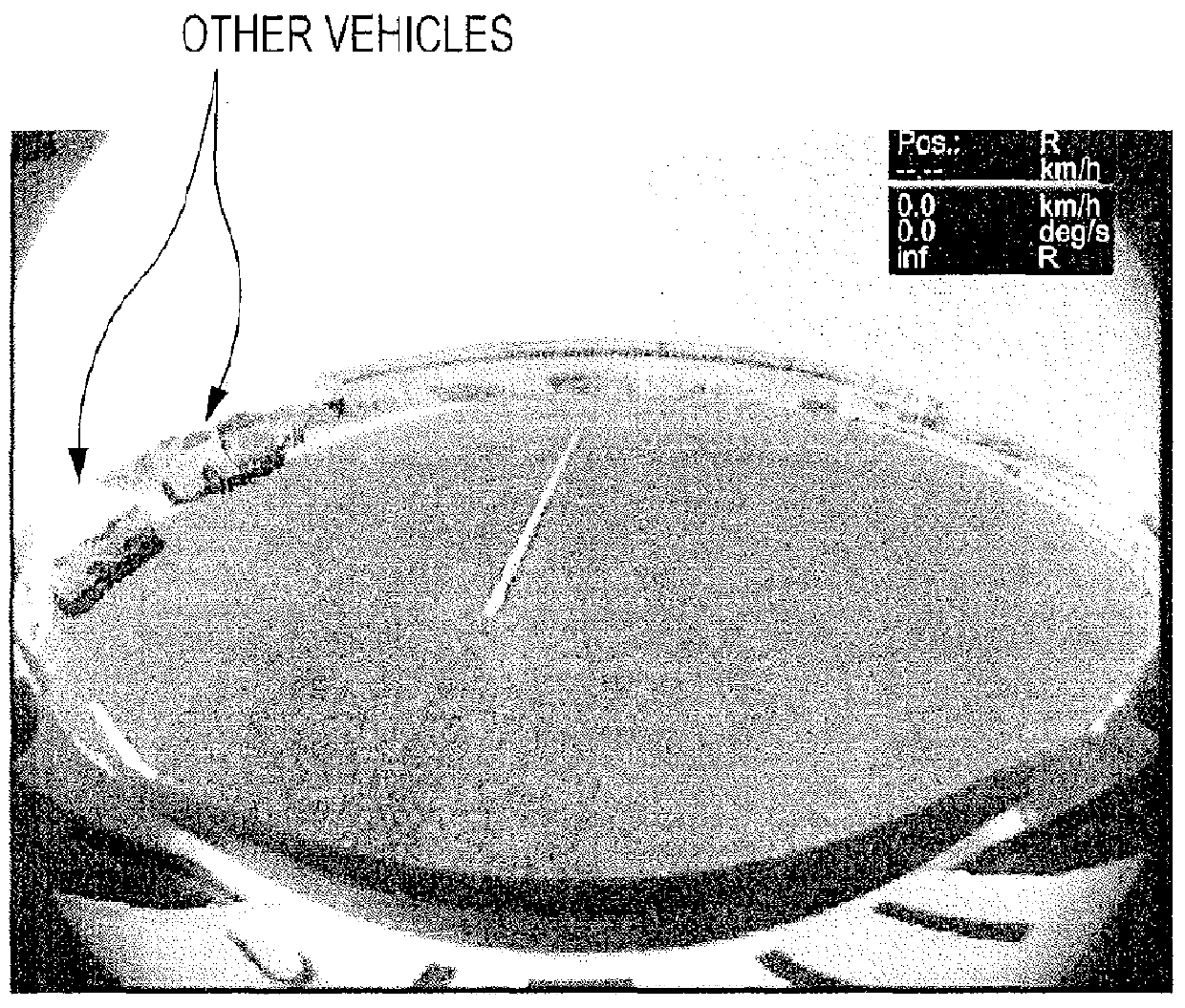

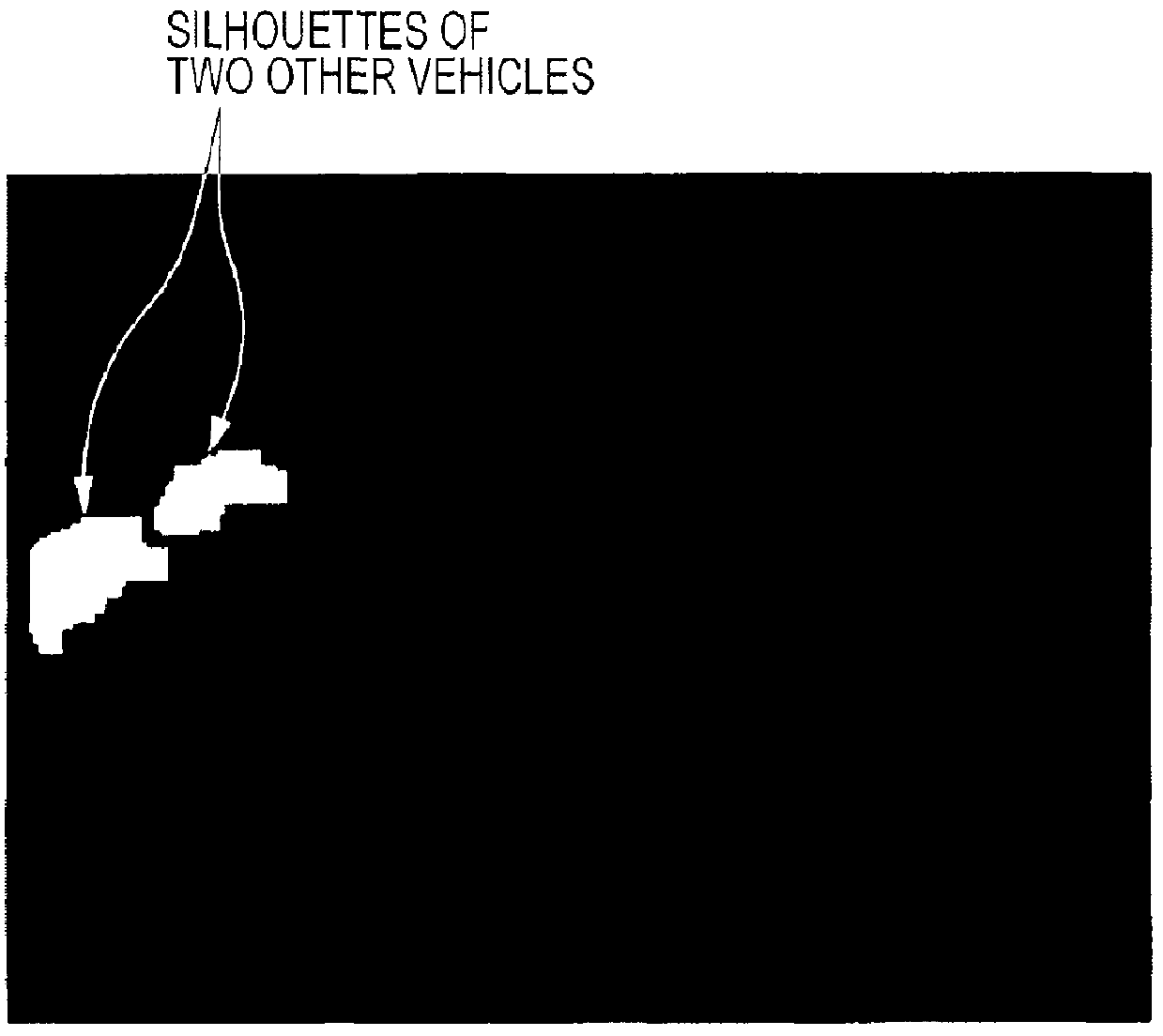

3D Object Detecting Apparatus and 3D Object Detecting Method

ActiveUS20120219183A1Simple configurationAccuracy can be improved and stabilizedImage enhancementTelevision system detailsHigh densityImage detection

A 3D-object detecting apparatus may include a detection-image creating device configured to detect a 3D object on an image-capture surface from an image captured by an image-capture device and to create a detection image in which a silhouette of only the 3D object is left; a density-map creating device configured to determine the 3D objects spatial densities at corresponding coordinate points in a coordinate plane on the basis of the detection image and mask images obtained for the corresponding coordinate points on the basis of virtual cuboids arranged for the corresponding coordinate points and to create a density map having pixels for the corresponding coordinate points such that the pixels have pixel values corresponding to the determined spatial densities; and a 3D-object position detecting device that detects the position of the 3D object as a representative point in a high-density region in the density map.

Owner:ALPINE ELECTRONICS INC

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN100500308CReduce maintenance costsImprove operational efficiencyFlush cleaningCleaning using liquidsDevice formHigh pressure water

Owner:CHINA UNIV OF MINING & TECH

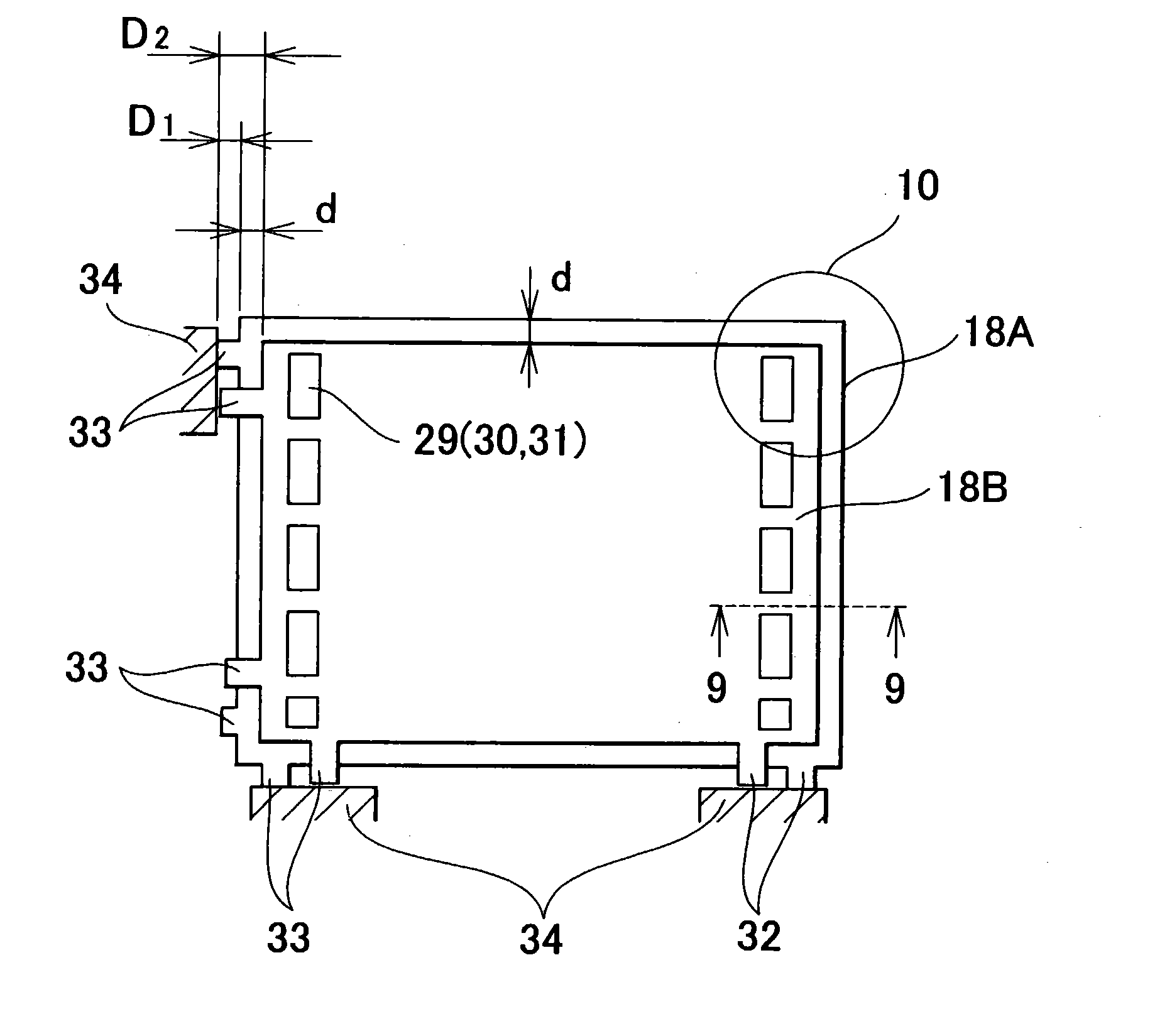

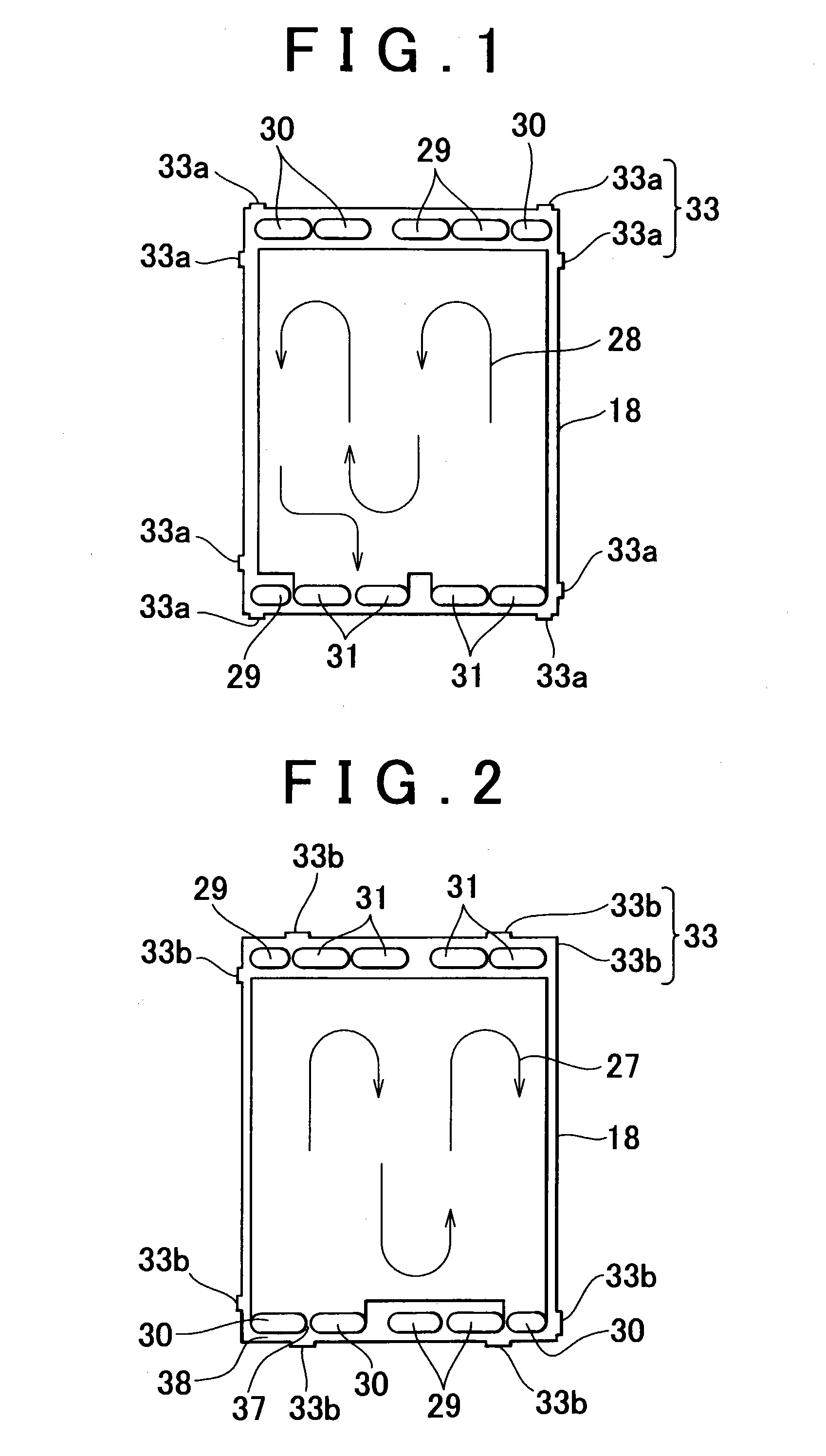

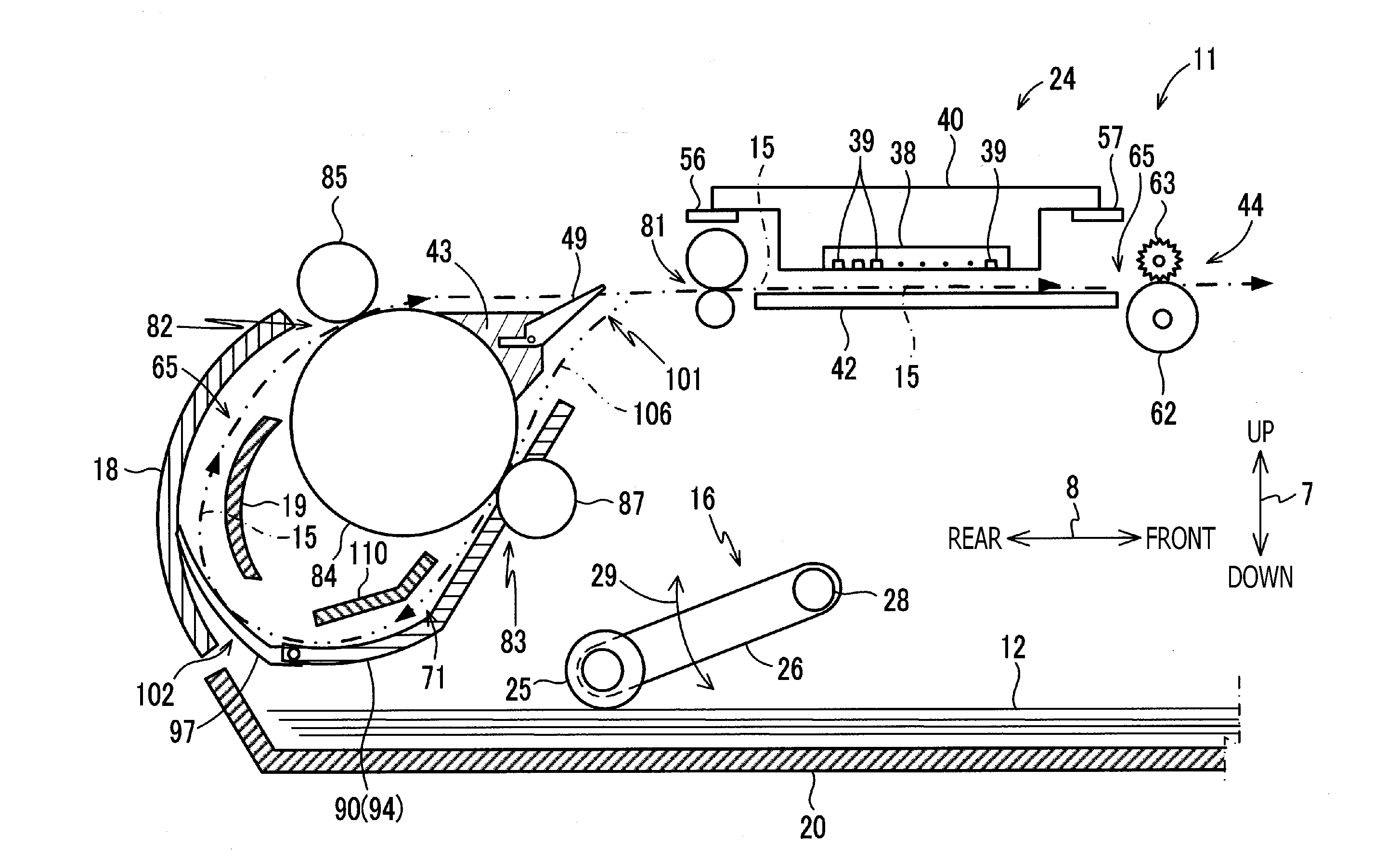

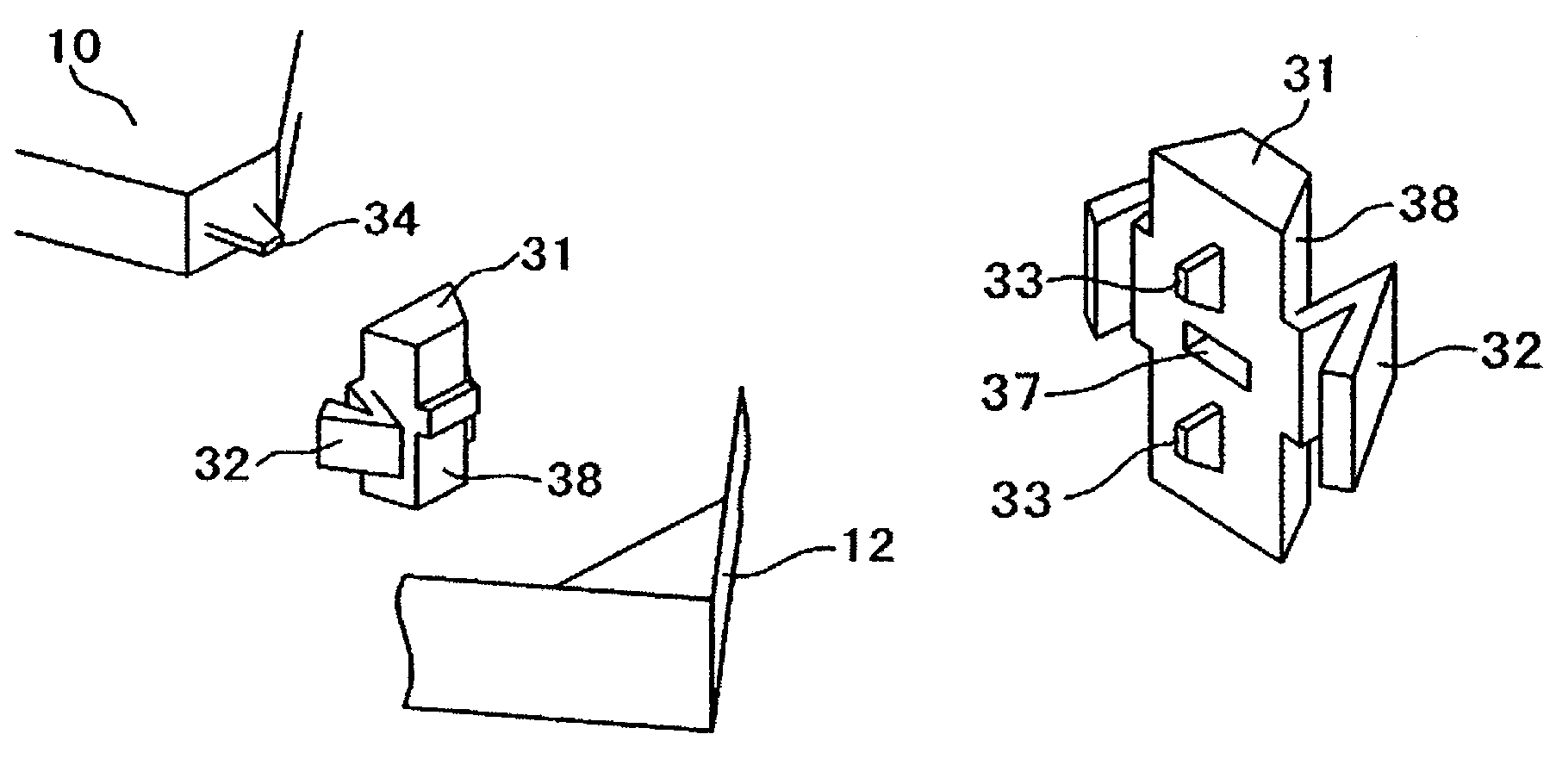

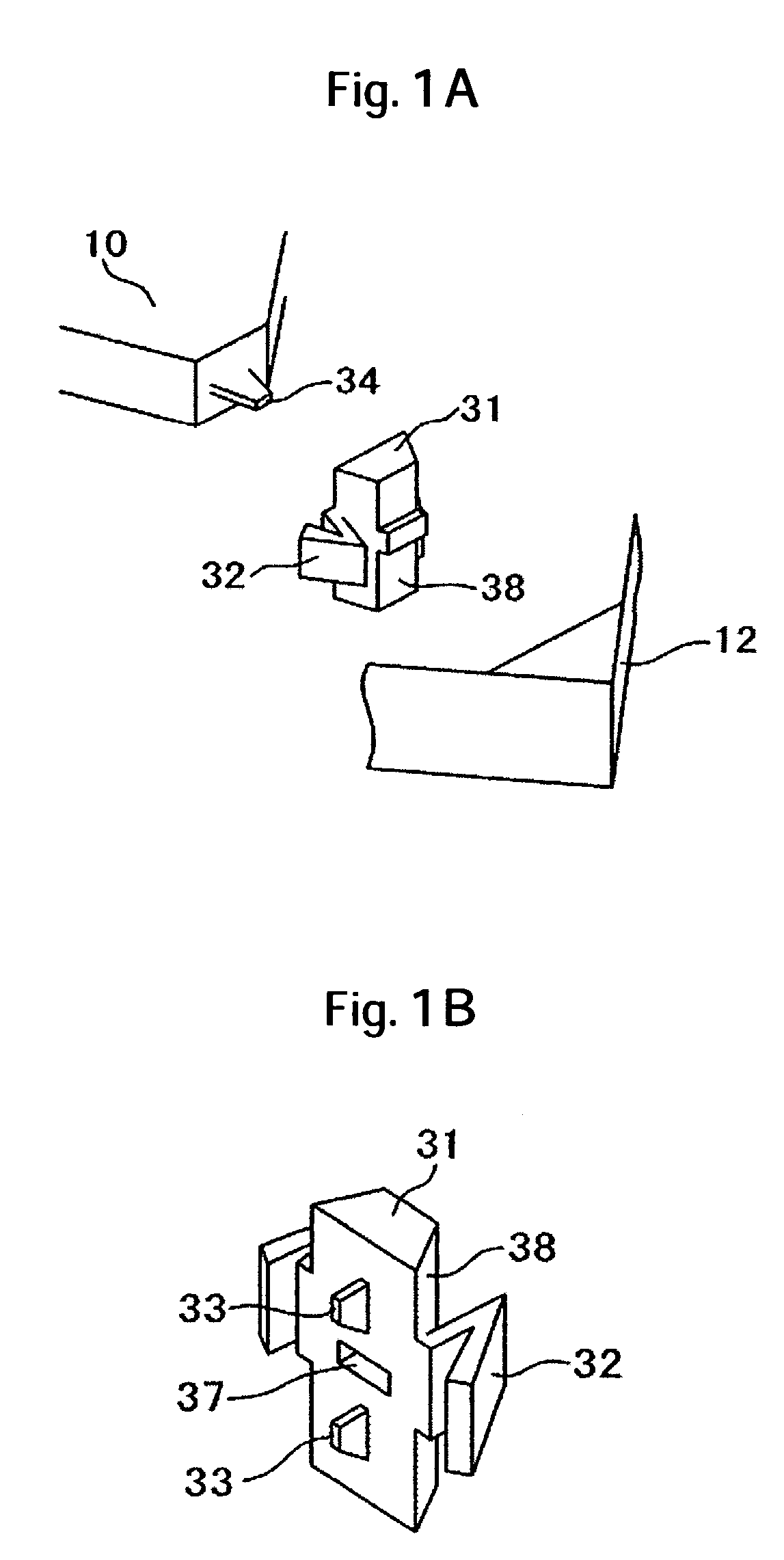

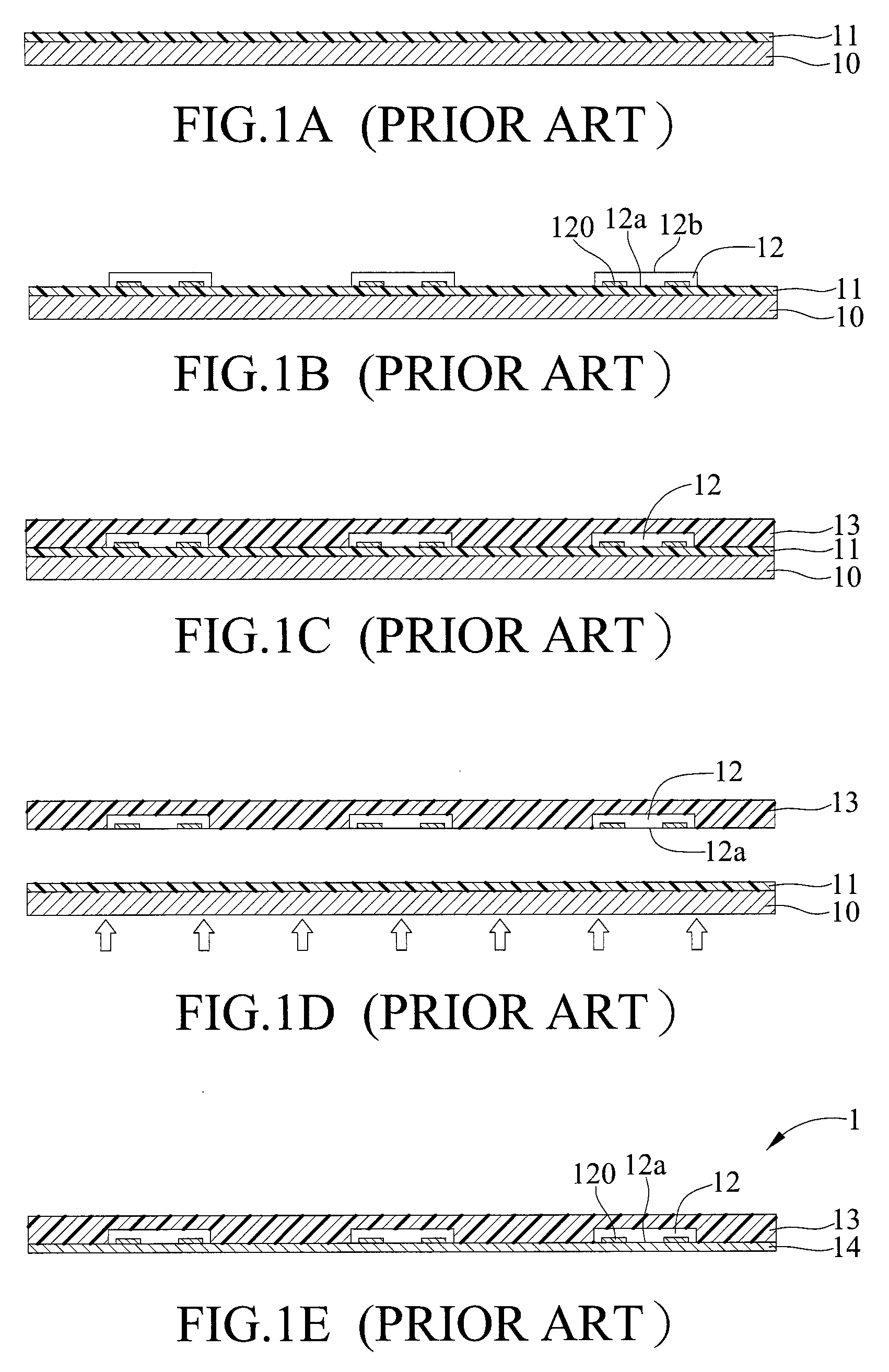

Sealing structure of fuel cell and manufacturing method of same

ActiveUS20040023099A1Reduce positioning accuracyAvoid positioning accuracyFuel cells groupingFinal product manufactureComing outFuel cells

A stack structure of a fuel cell according to an aspect of the invention includes a plurality of separators of the fuel cell, and a protruding portion which has a tip portion that contacts a reference portion of an assembly jig during assembly of the fuel cell. Since the tip portion of the protruding portion contacts the reference portion of the assembly jig, an adhesive agent does not come out from the tip portion of the protruding portion. Therefore, it is possible to prevent positioning accuracy in stacking cells from being reduced. The reduction of the positioning accuracy is due to adhesion of the spreading adhesive agent to the reference portion of the assembly jig. In addition, it is possible to prevent a short-circuit from occurring. The occurrence of the short-circuit is due to deformation of the separator caused by making the separator contact the reference portion of the assembly jig.

Owner:TOYOTA JIDOSHA KK

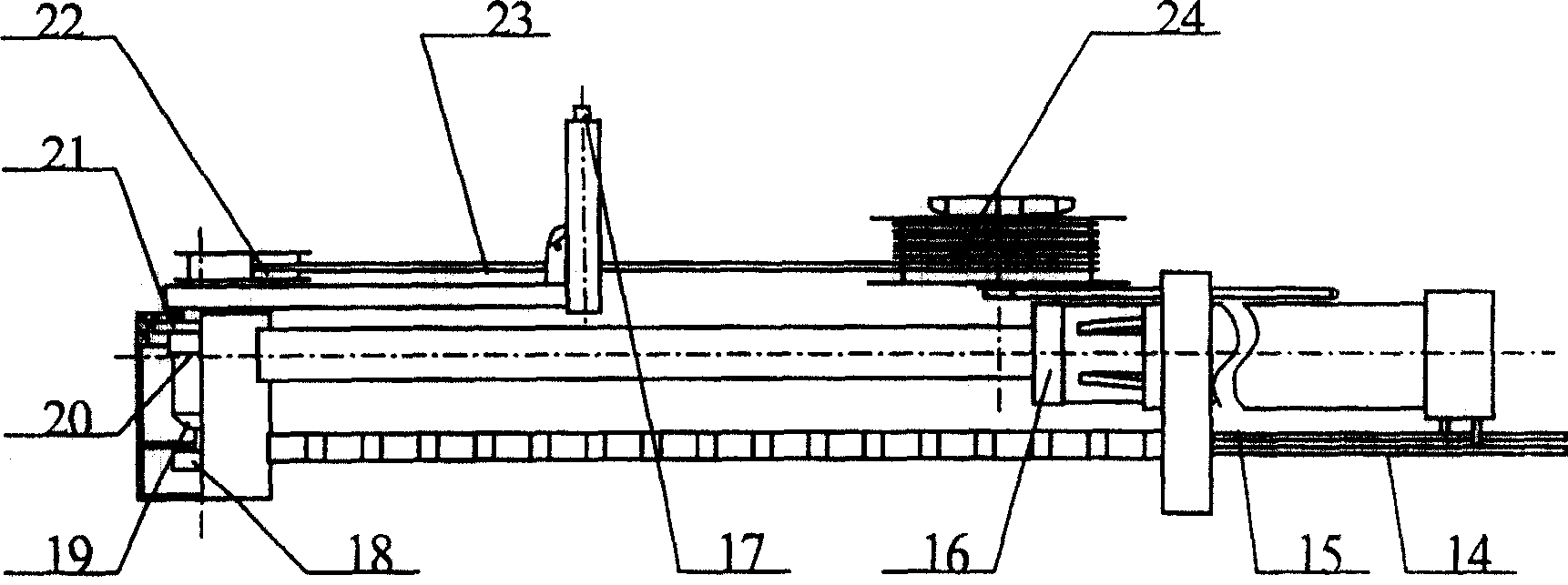

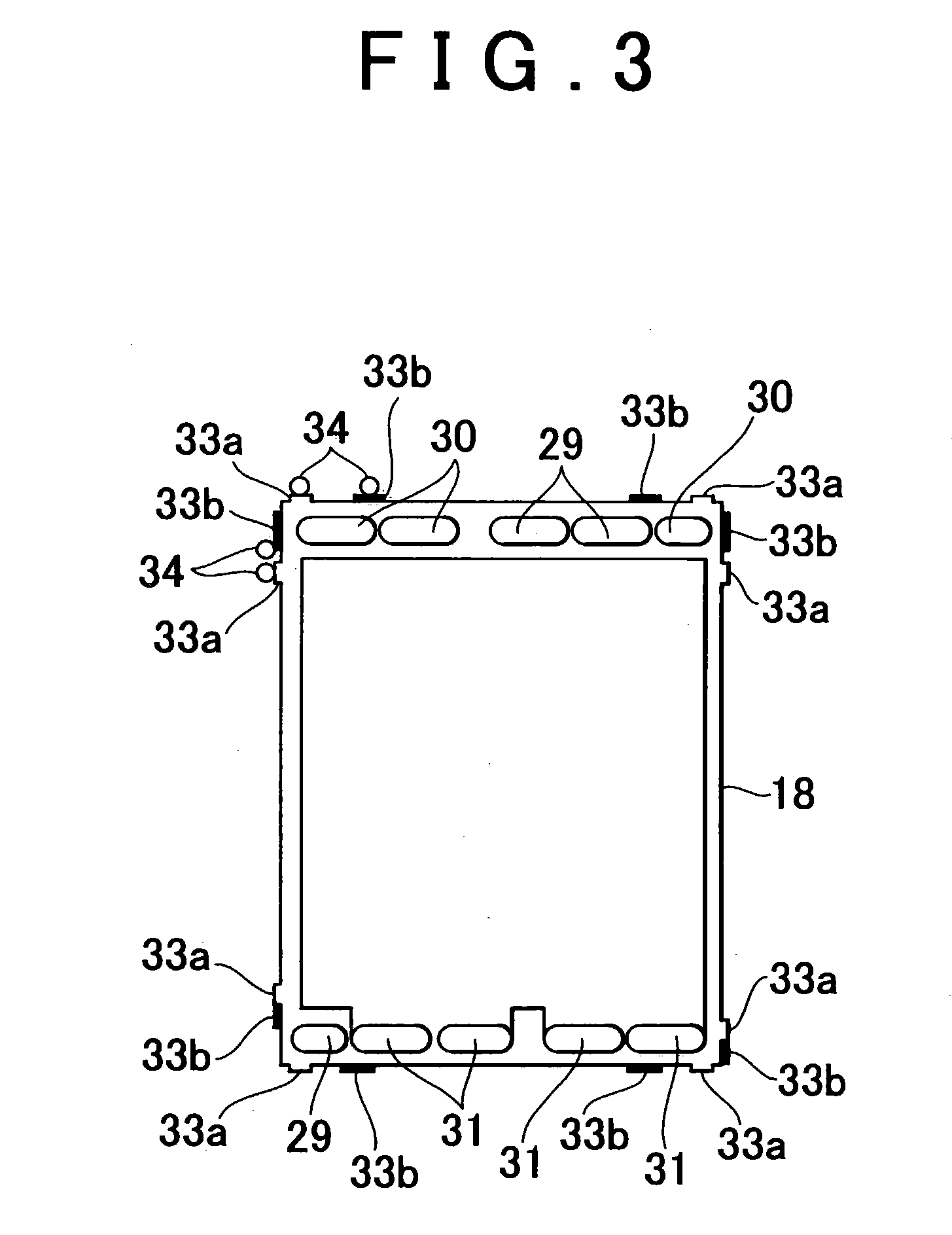

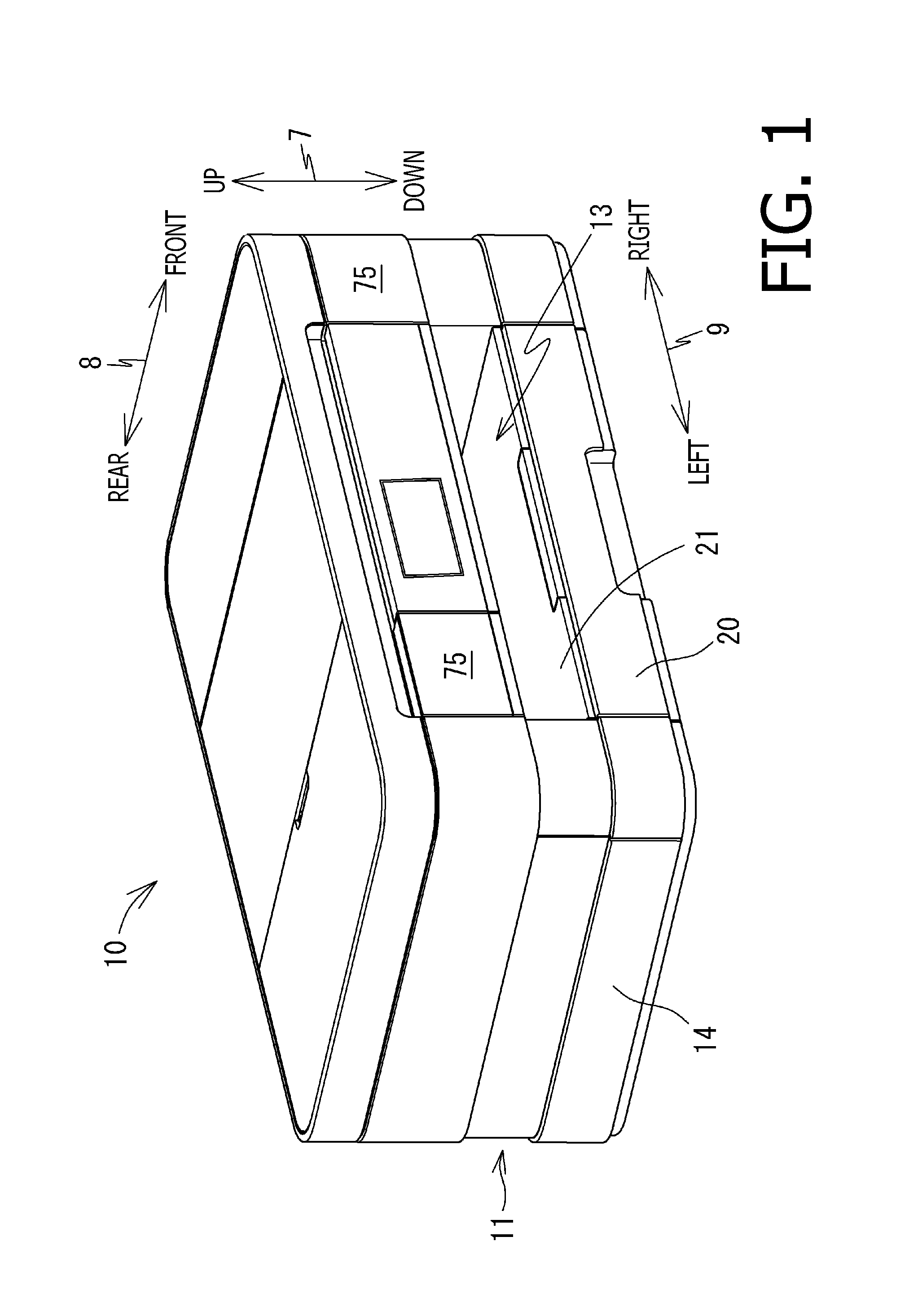

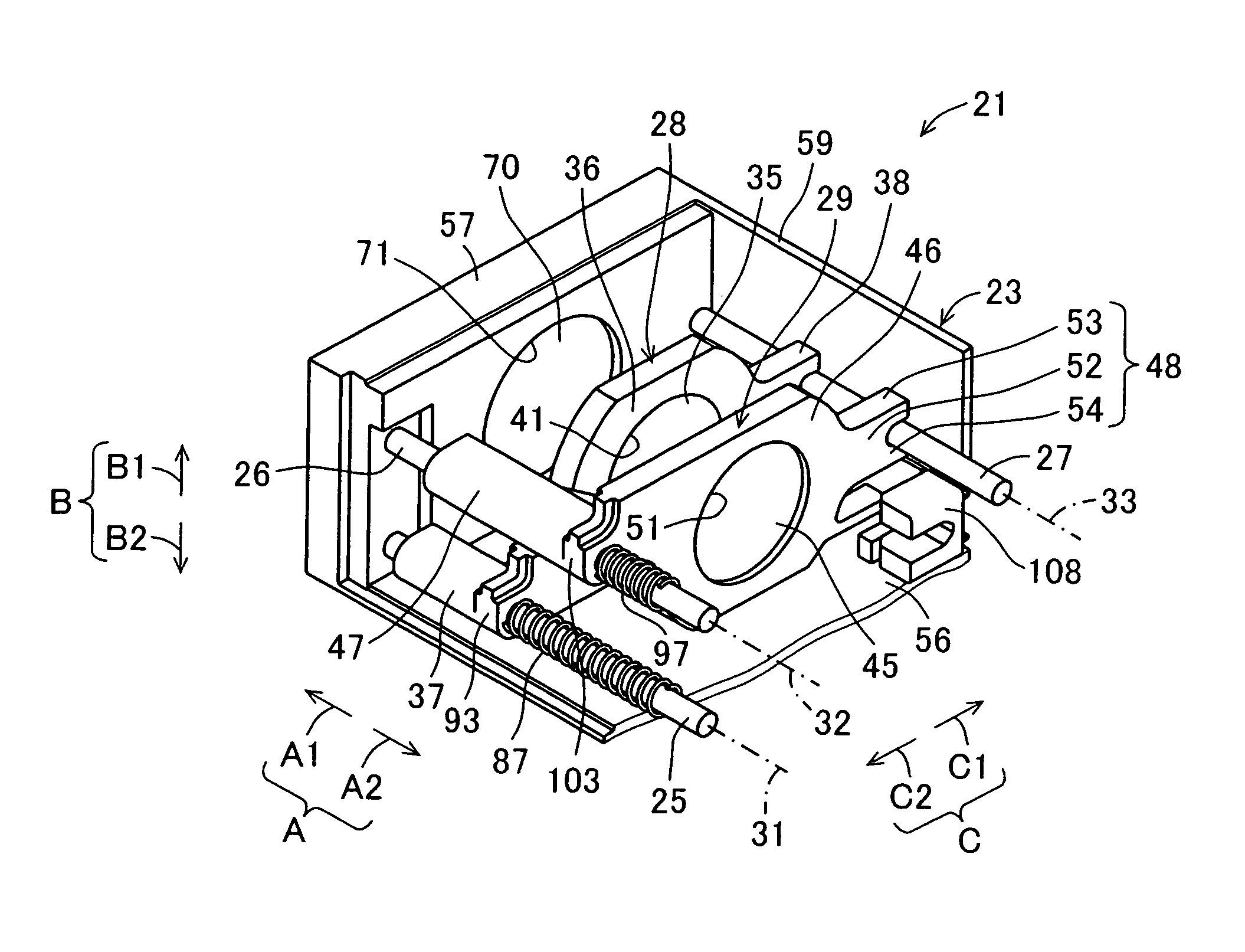

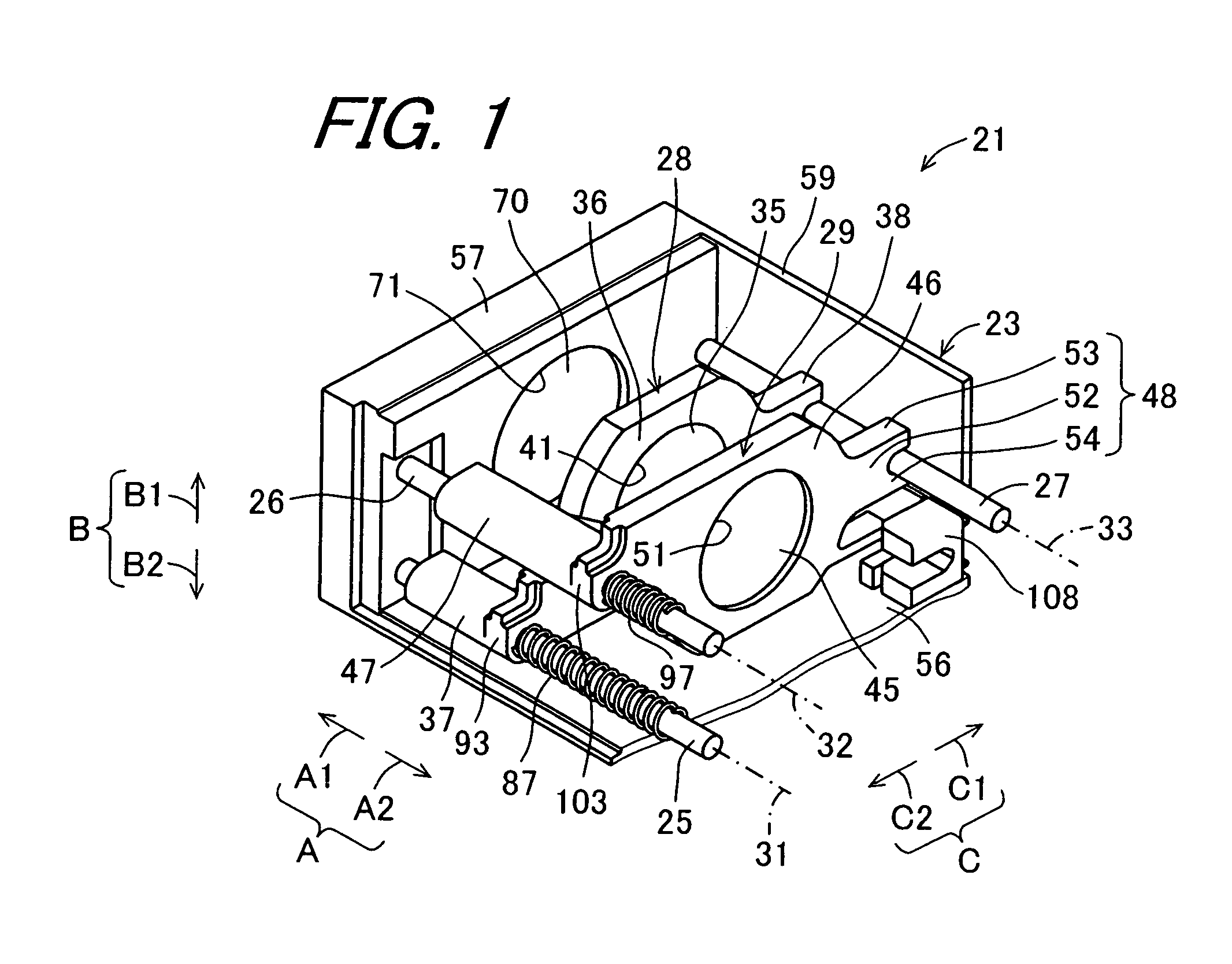

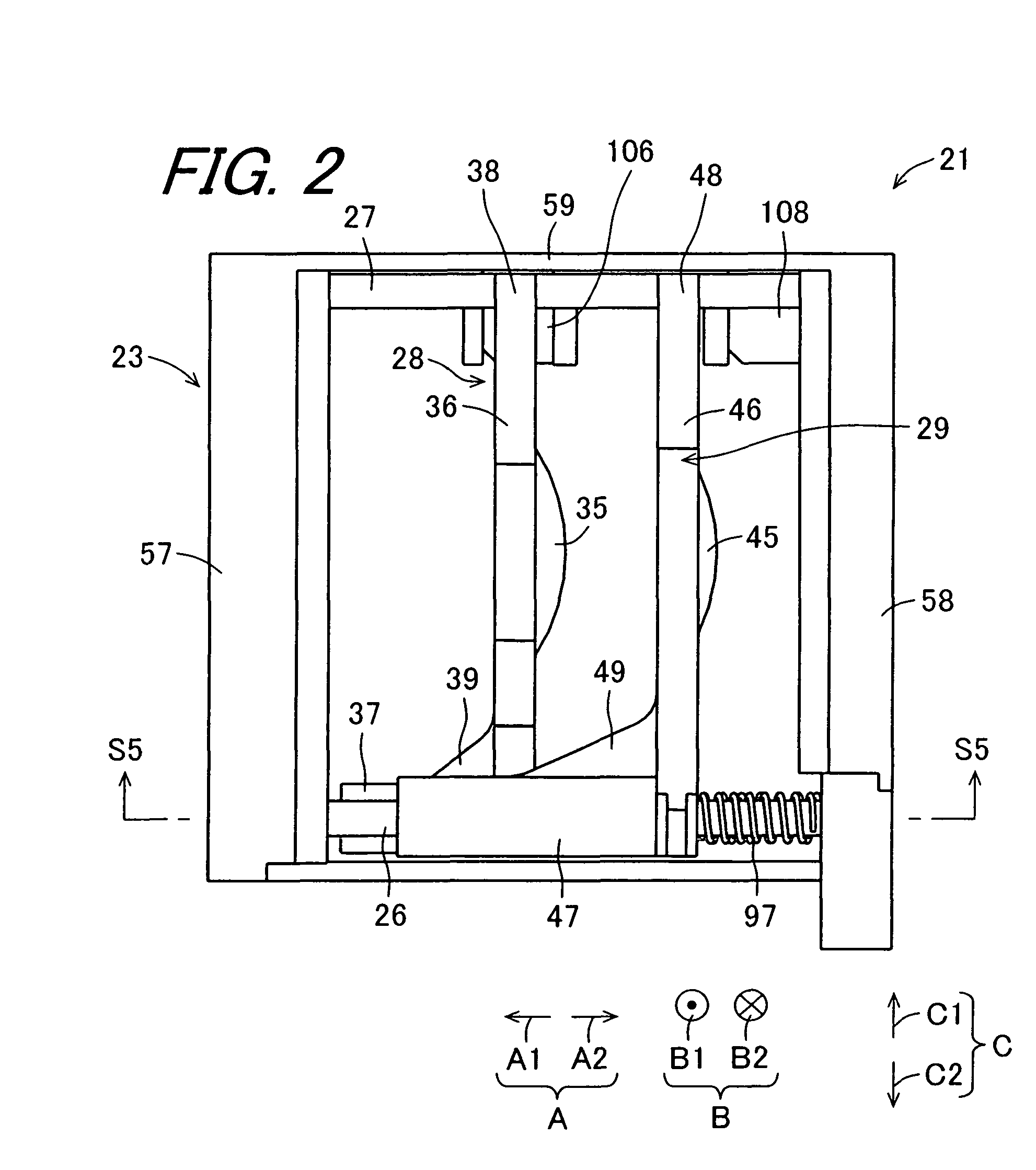

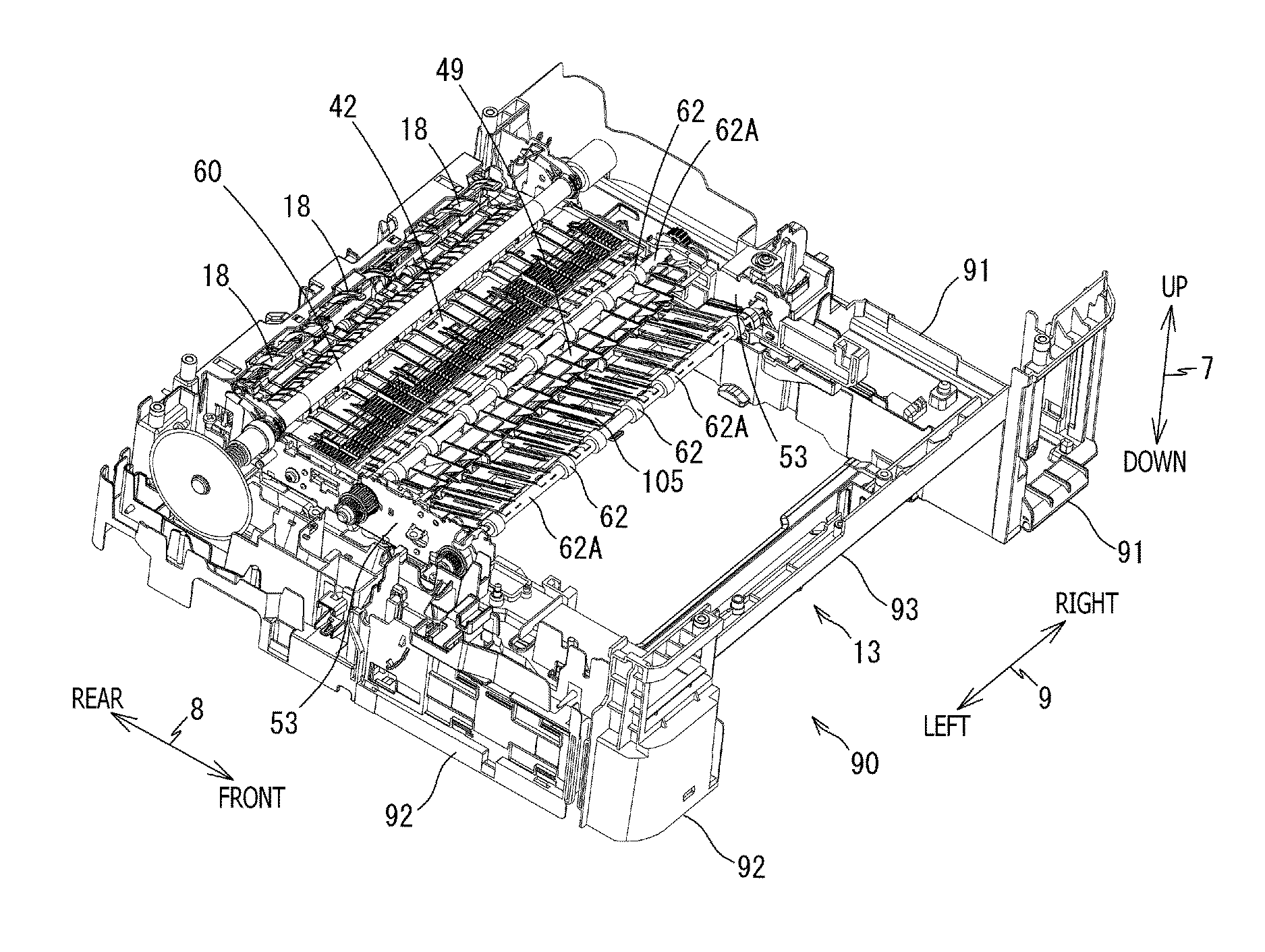

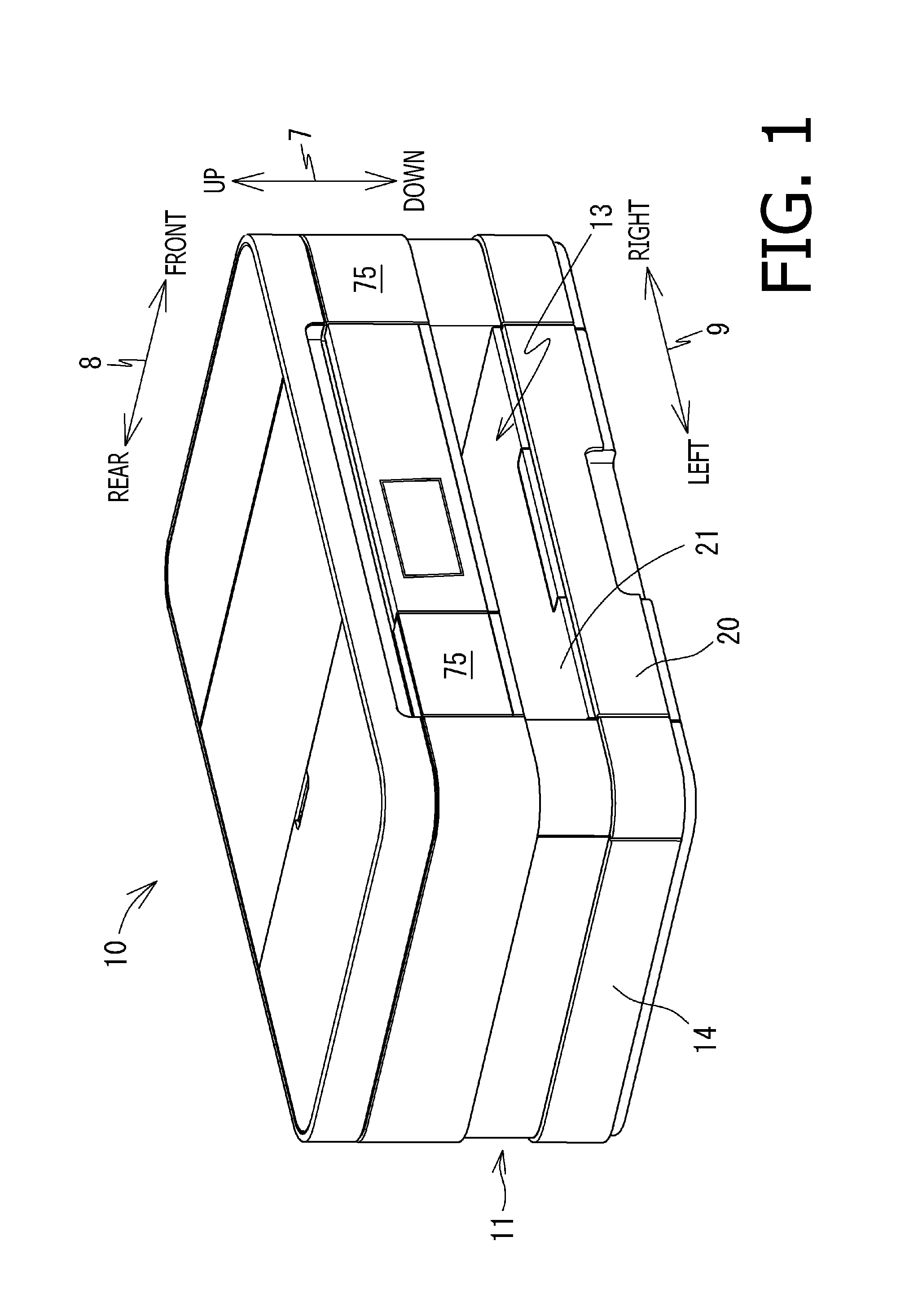

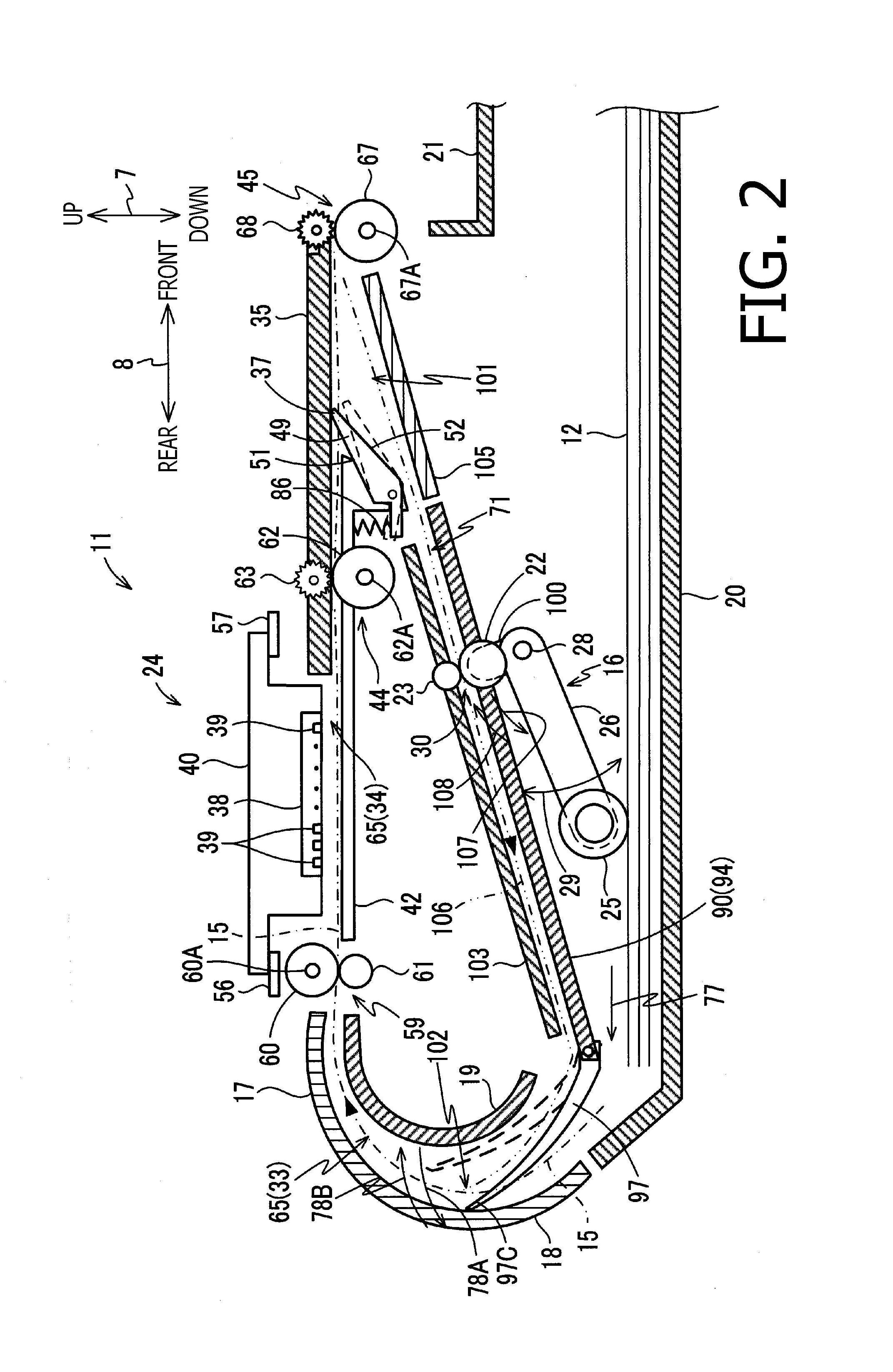

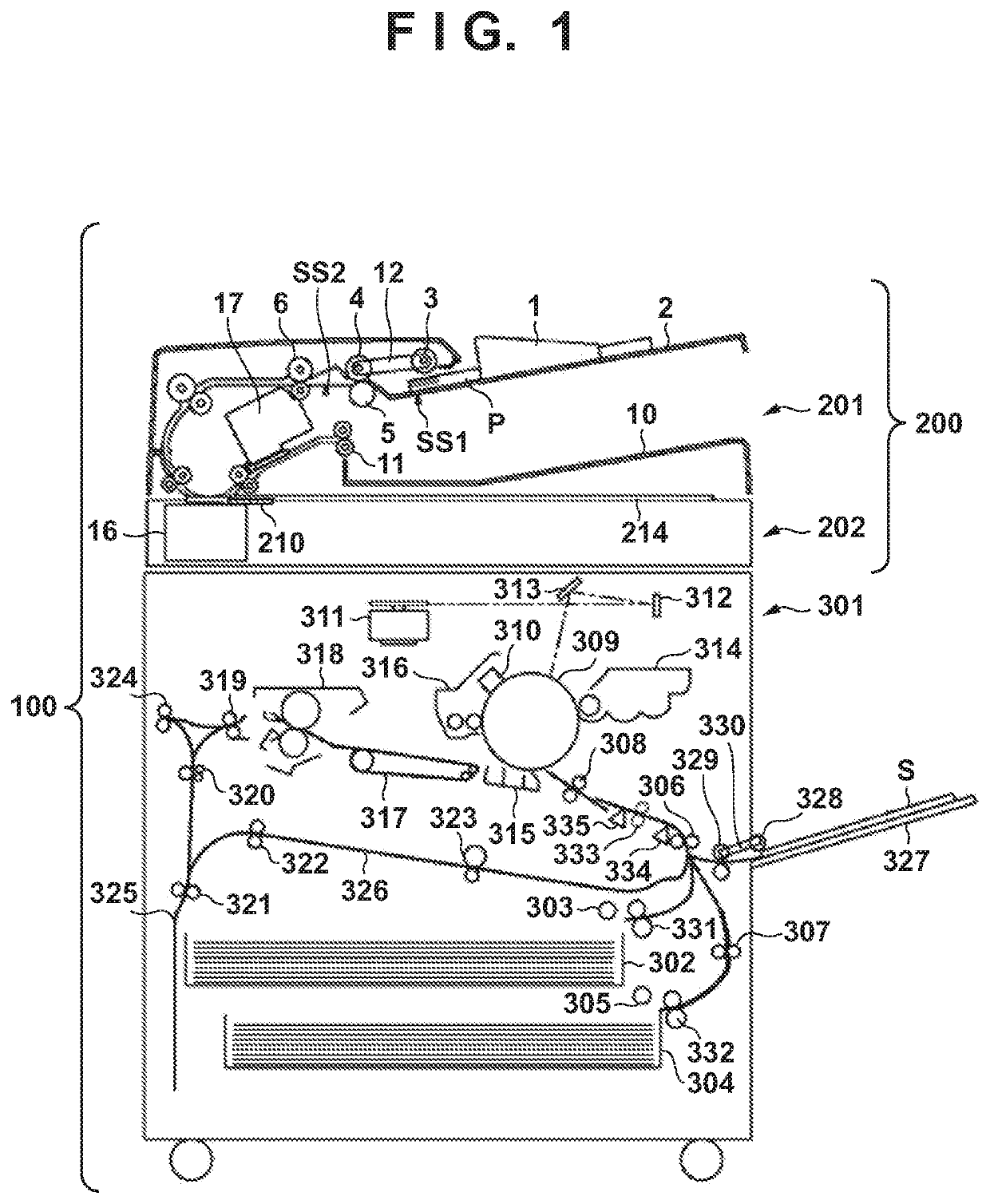

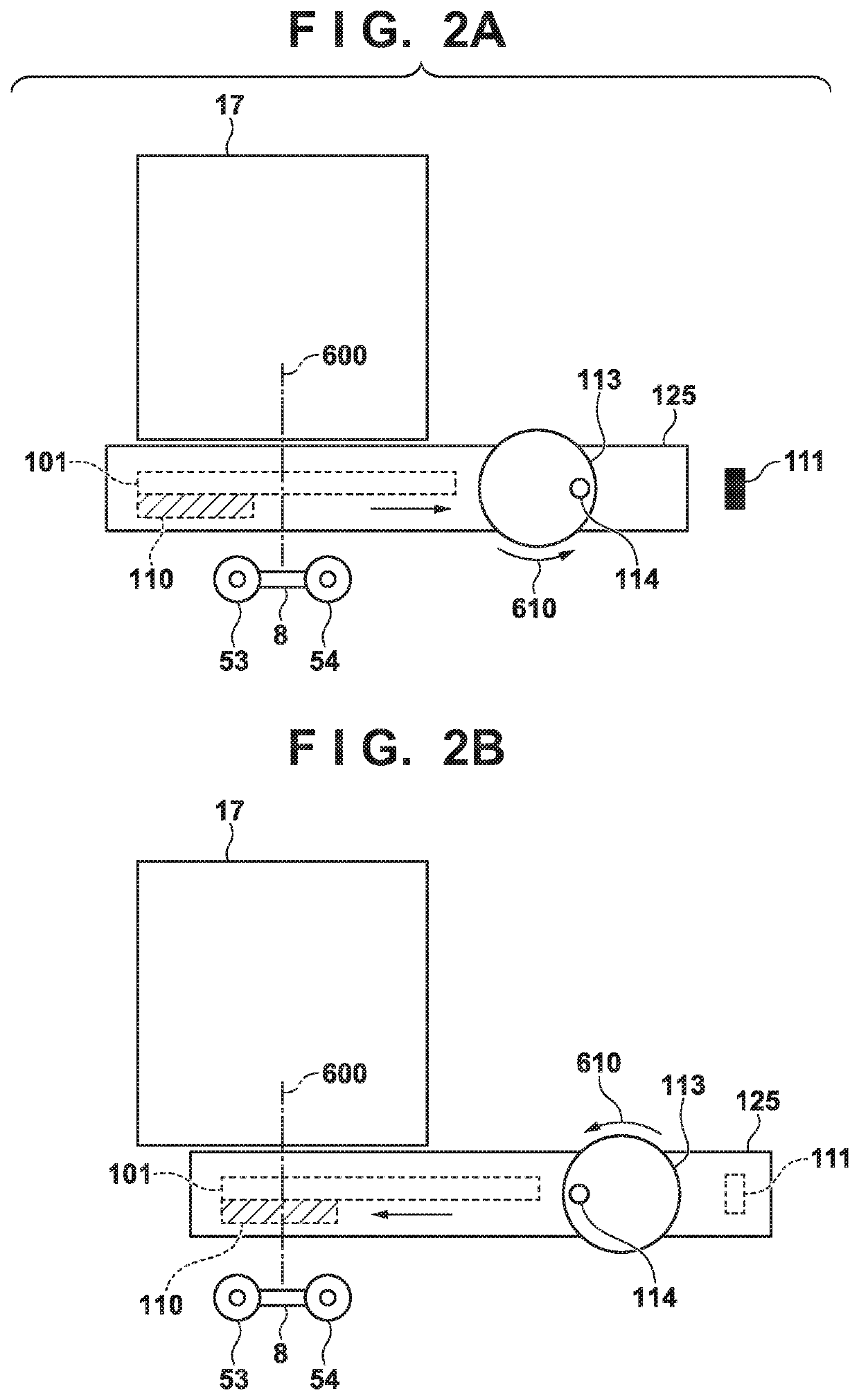

Image recording apparatus

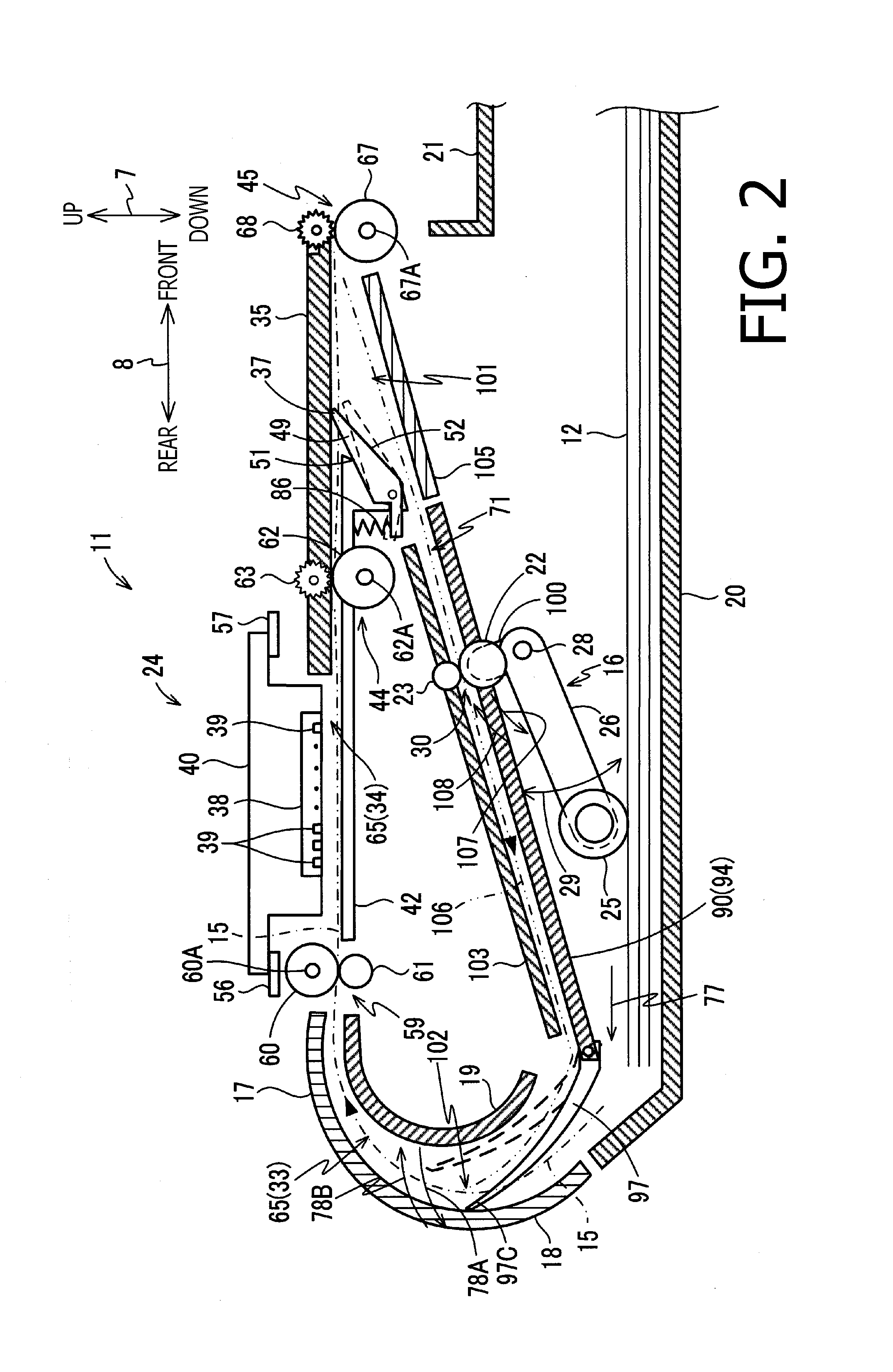

ActiveUS20160090258A1Reduce positioningPositional inaccuracy in the membersOverturning articlesArticle feedersDrive shaftImage recording

An image recording apparatus, including a tray configured to support a sheet; a chassis defining a first conveyer path, in which the sheet on the tray is conveyed in a first conveying direction, and a second conveyer path, through which the sheet is conveyed in a second conveying direction through a branch point to be inverted to reenter the first conveyer path through a merging point; a base member integrally formed of resin and including a guiding section to define a form of a part of the second conveyer path; a recording unit to record an image on the sheet conveyed in the first conveyer path; a drive shaft supported by the base member; and a return-conveyer roller disposed in the second conveyer path and configured to convey the sheet to be guided on the guiding section in the second conveying direction by rotation of the drive shaft, is provided.

Owner:BROTHER KOGYO KK

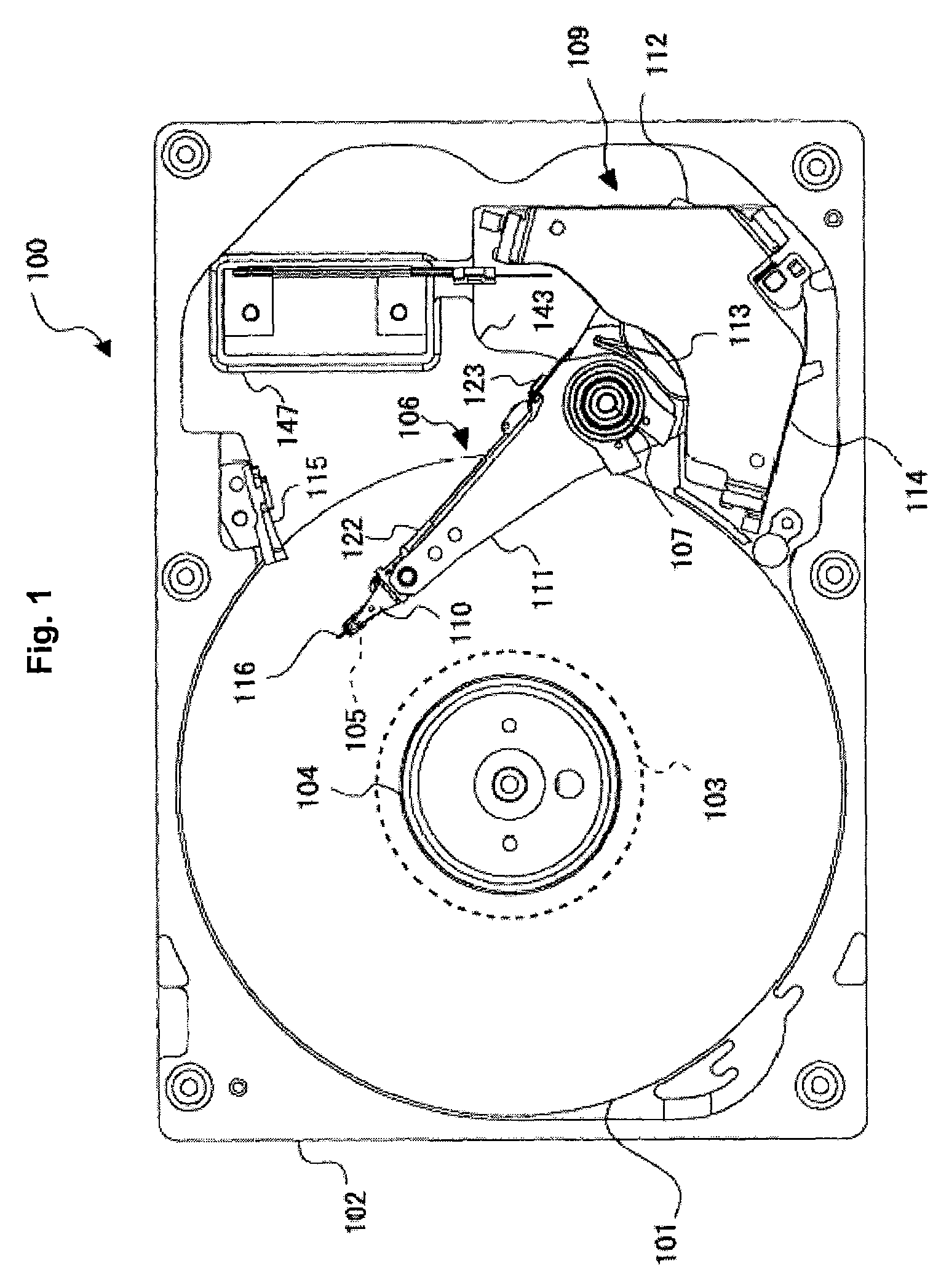

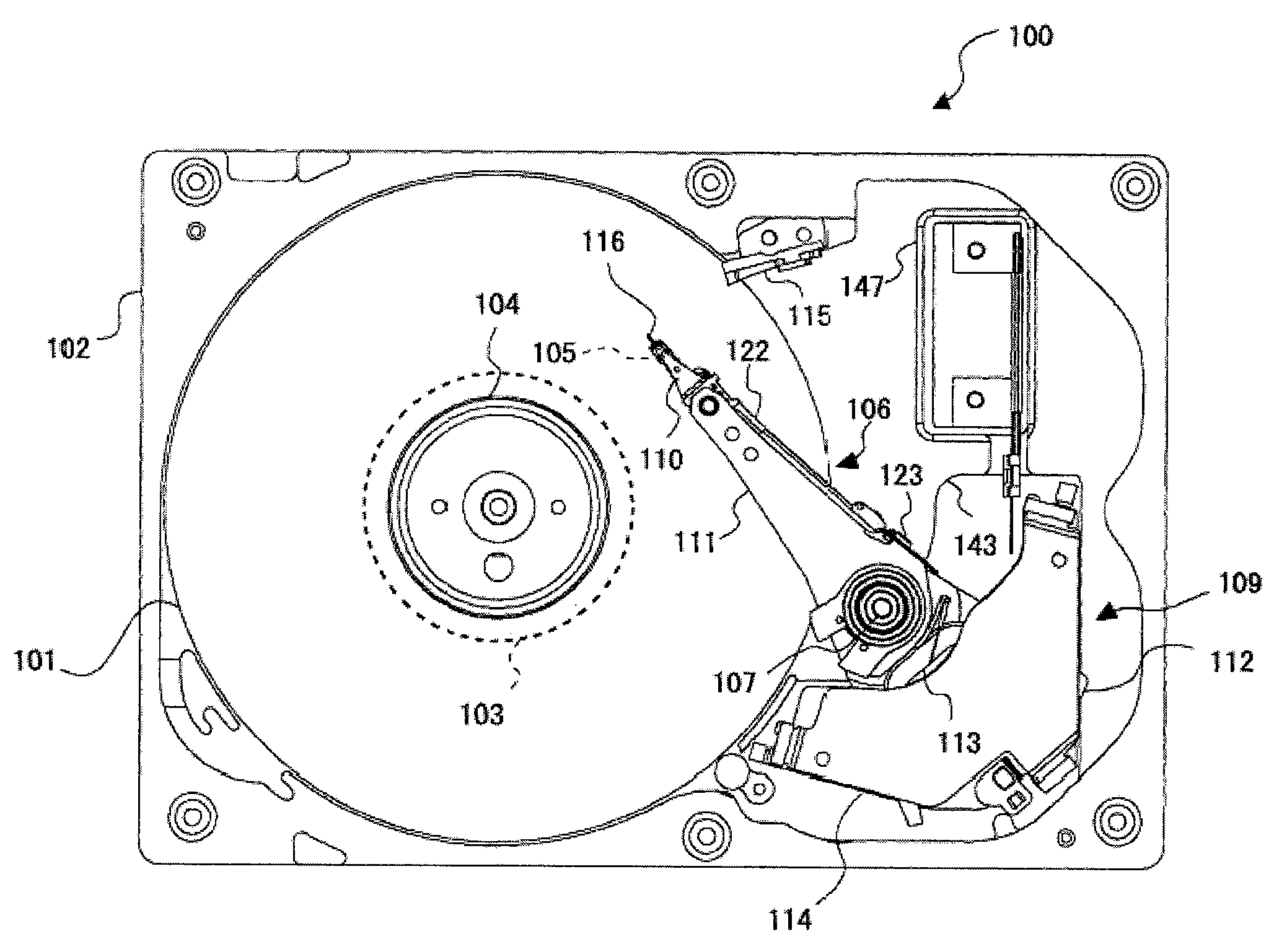

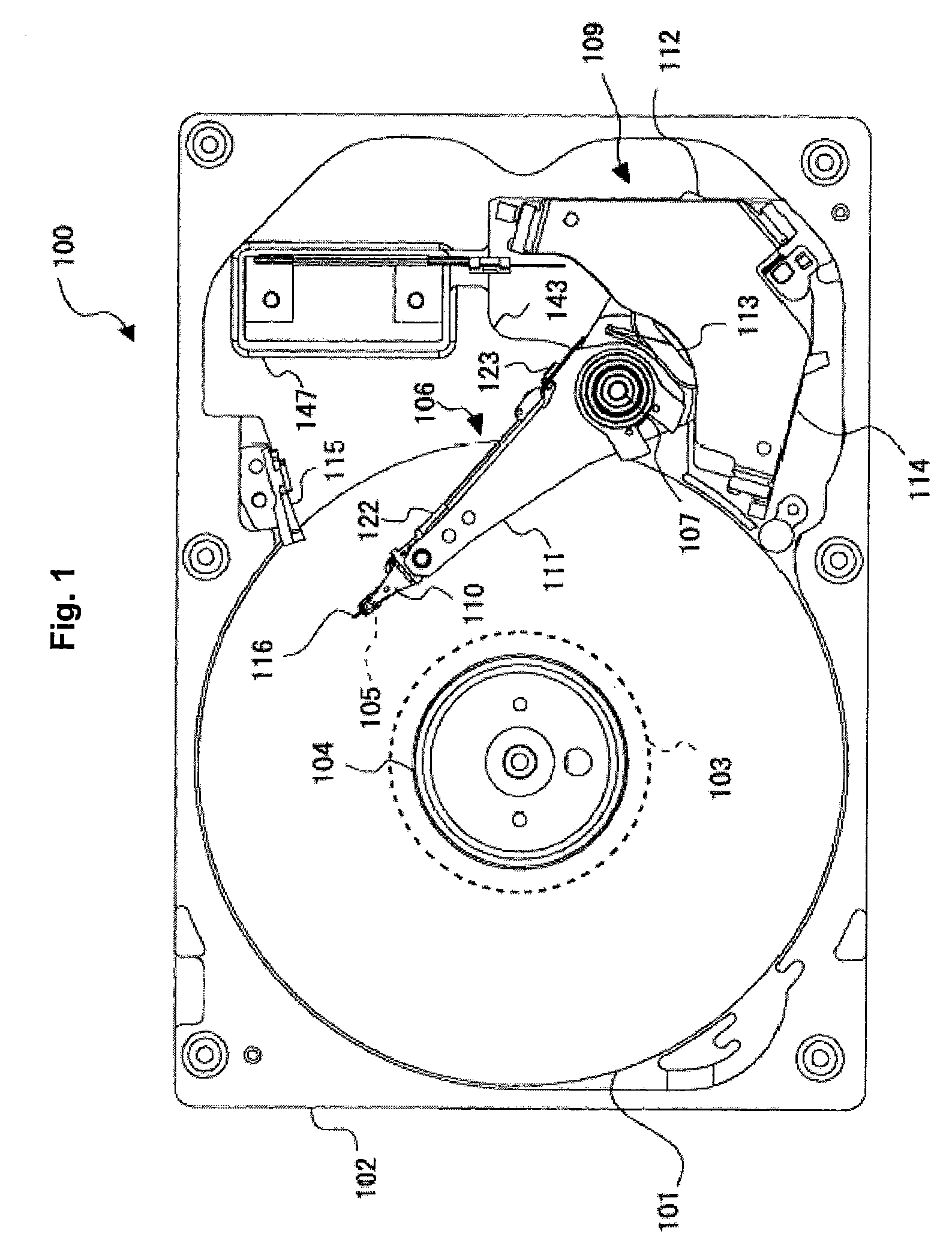

Magnetic disk drive with elastic support member

InactiveUS7535672B2High positioning accuracyAvoid positioning accuracyUndesired vibrations/sounds insulation/absorptionRecord information storageIn planeEngineering

Owner:WESTERN DIGITAL TECH INC

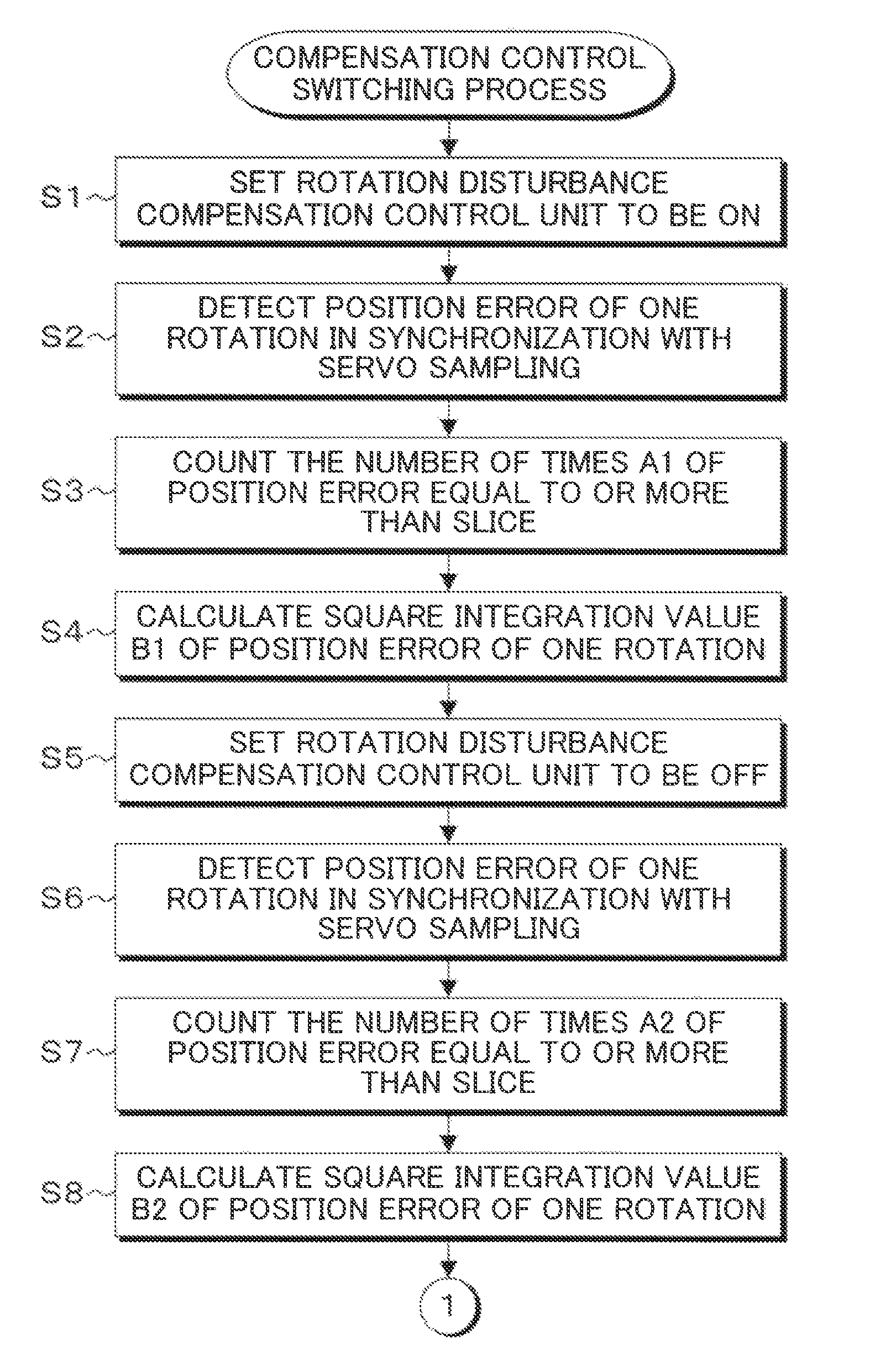

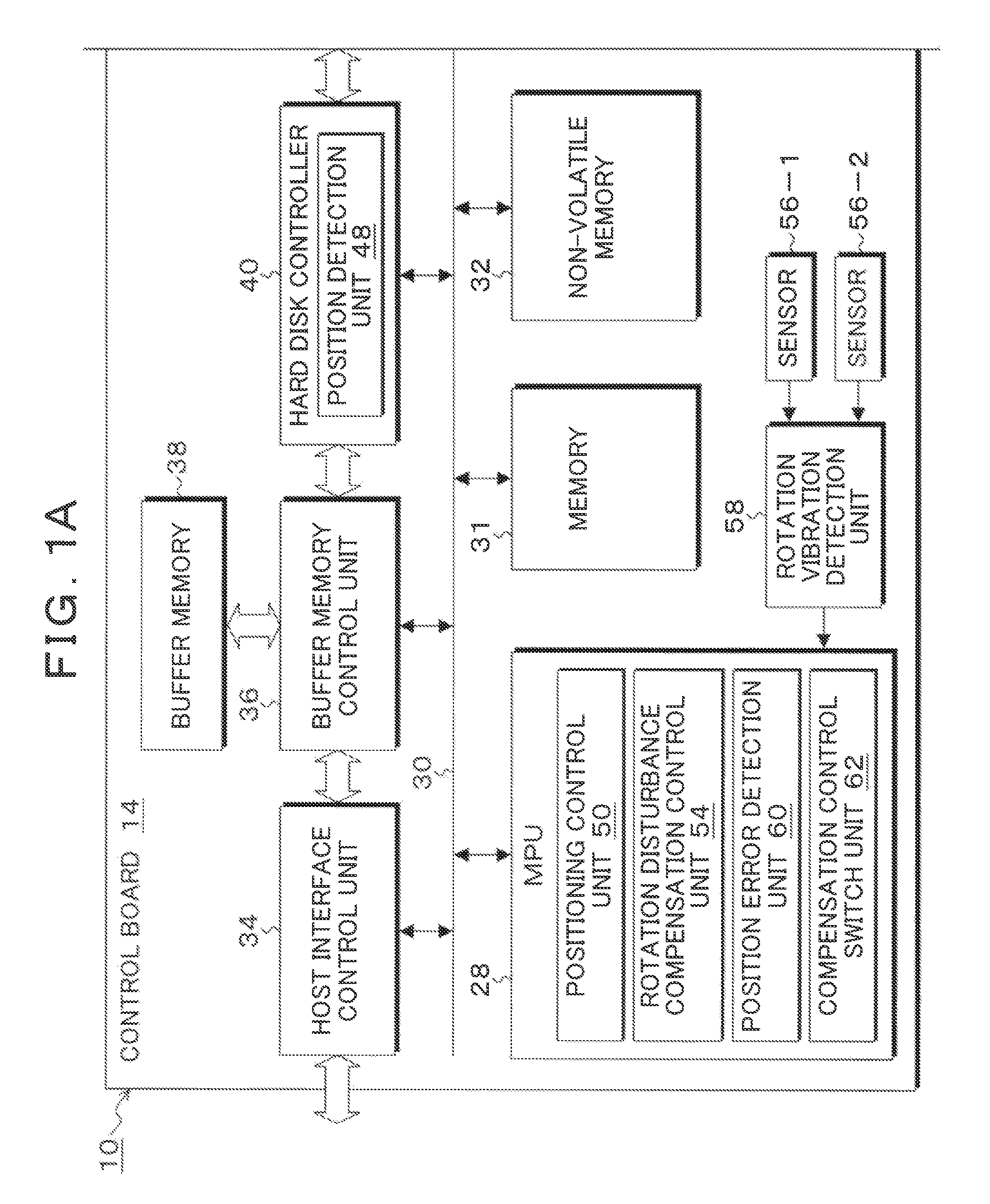

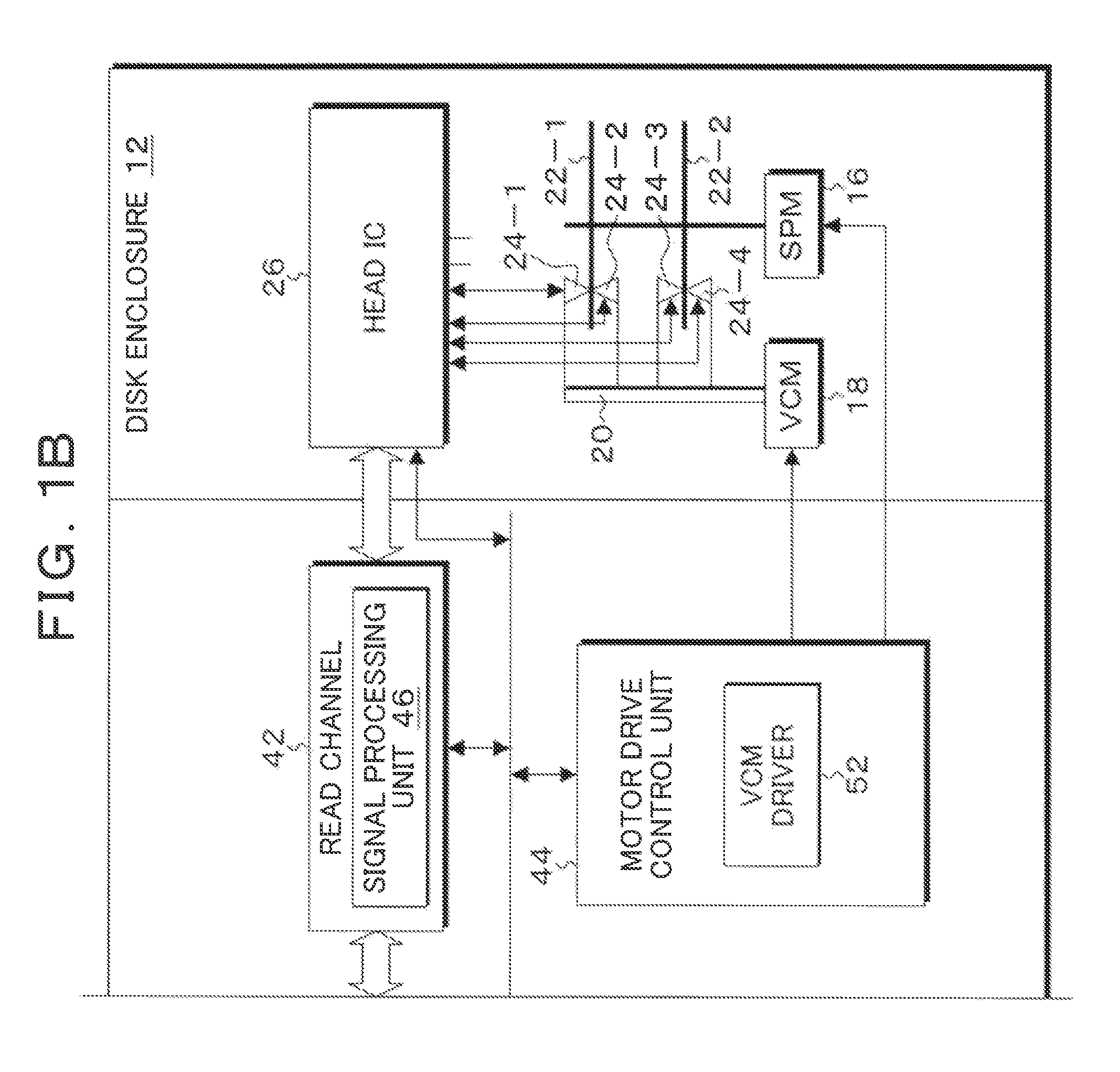

Storage apparatus, control method, and control device which enable or disable compensation control

ActiveUS7697234B2Avoid positioning accuracyHigh positioning accuracyTrack finding/aligningRecord information storagePosition errorPosition control

A rotation disturbance compensation control unit applies a compensation signal to a positioning control unit so as to cancel out rotation disturbance vibration components detected by using acceleration velocity sensors. At predetermined timing, a position error detection unit detects respective position errors of the case in which the rotation disturbance compensation control unit is turned on and the case in which it is turned off. A compensation control switching unit switches the rotation disturbance compensation control unit to be on if the position error of the case in which the compensation control of rotation disturbance is turned on is small and switches the compensation control switching unit to be off if the position error of the case in which the compensation control of rotation disturbance is turned off is small.

Owner:KK TOSHIBA

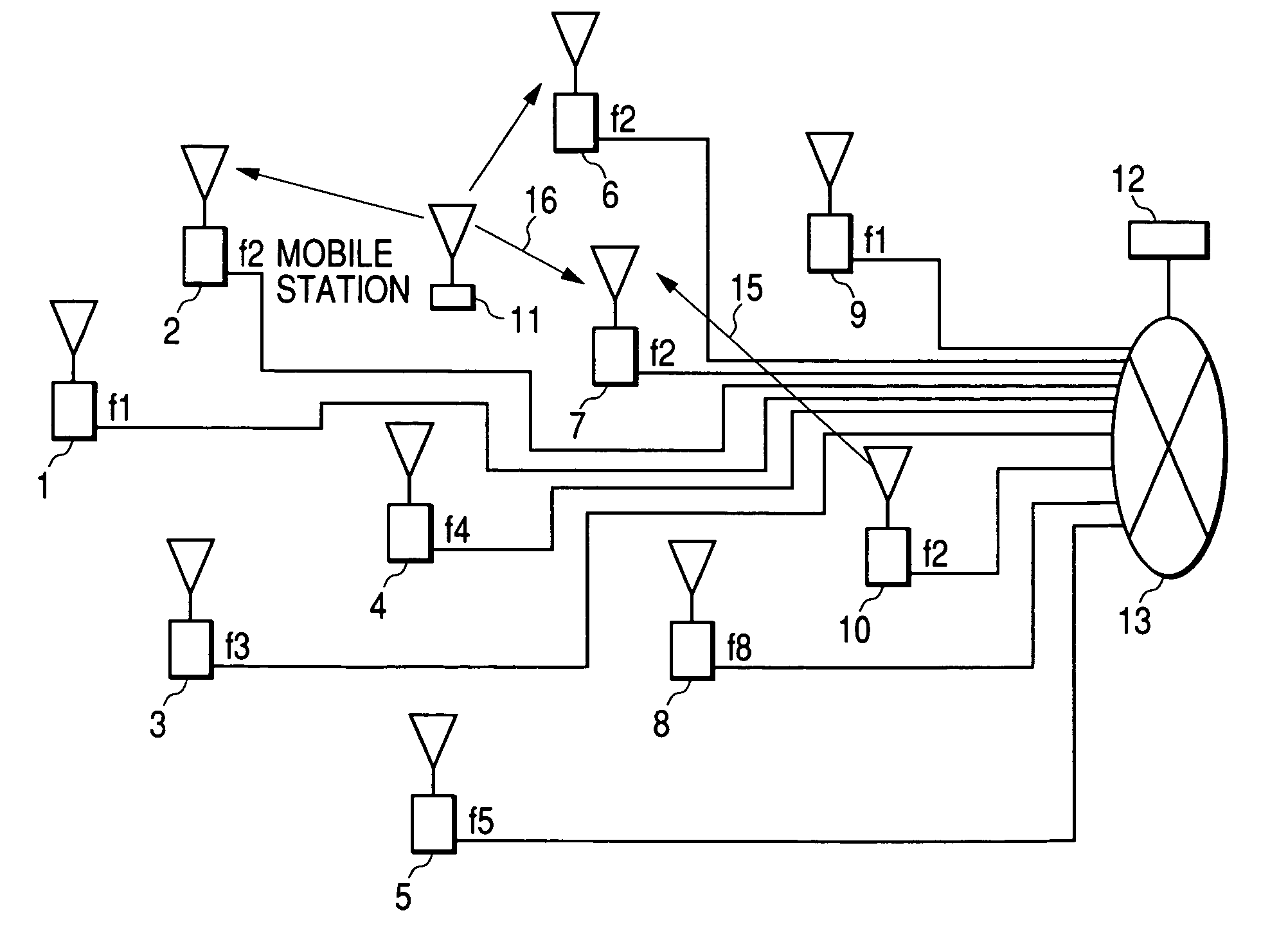

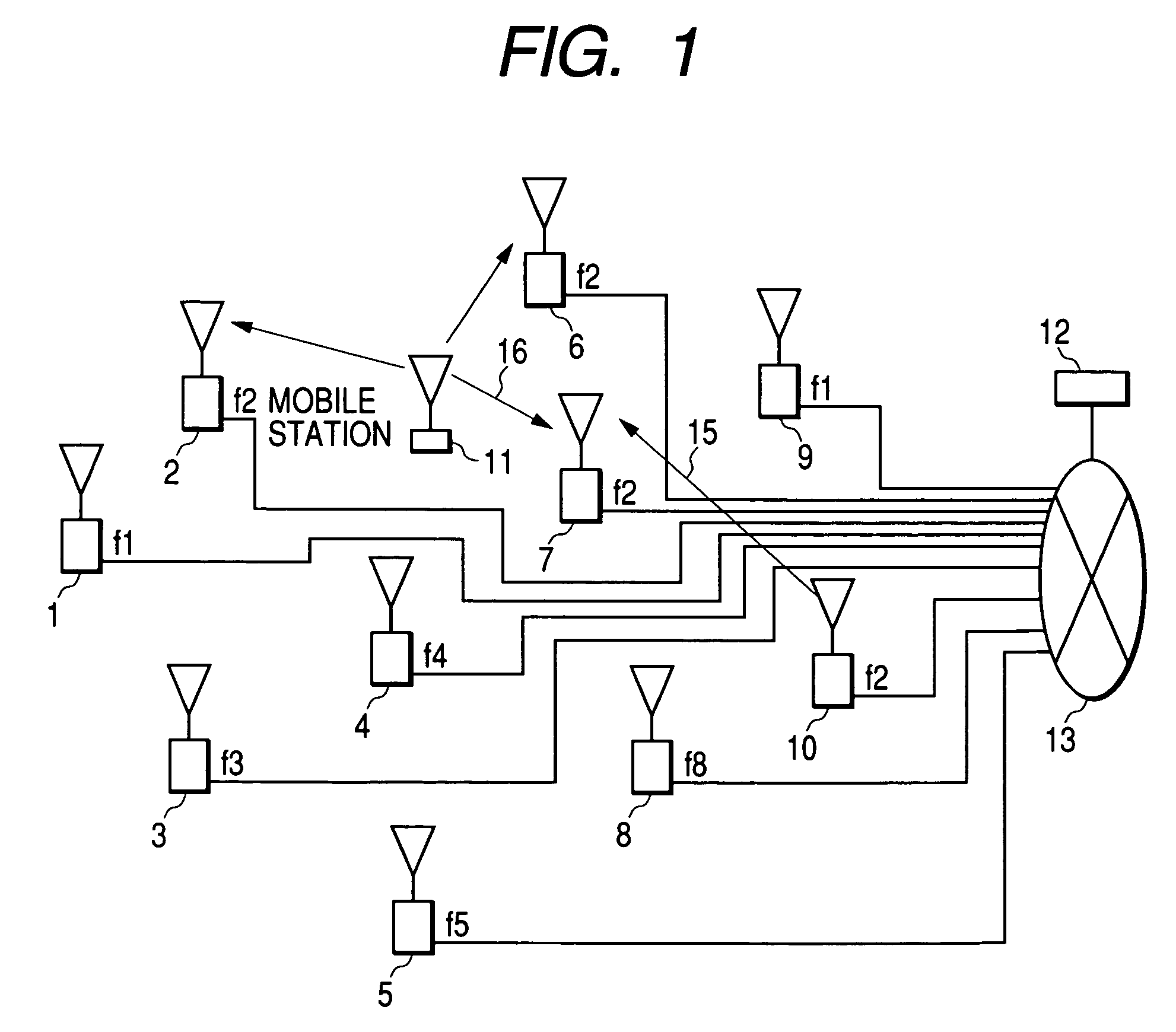

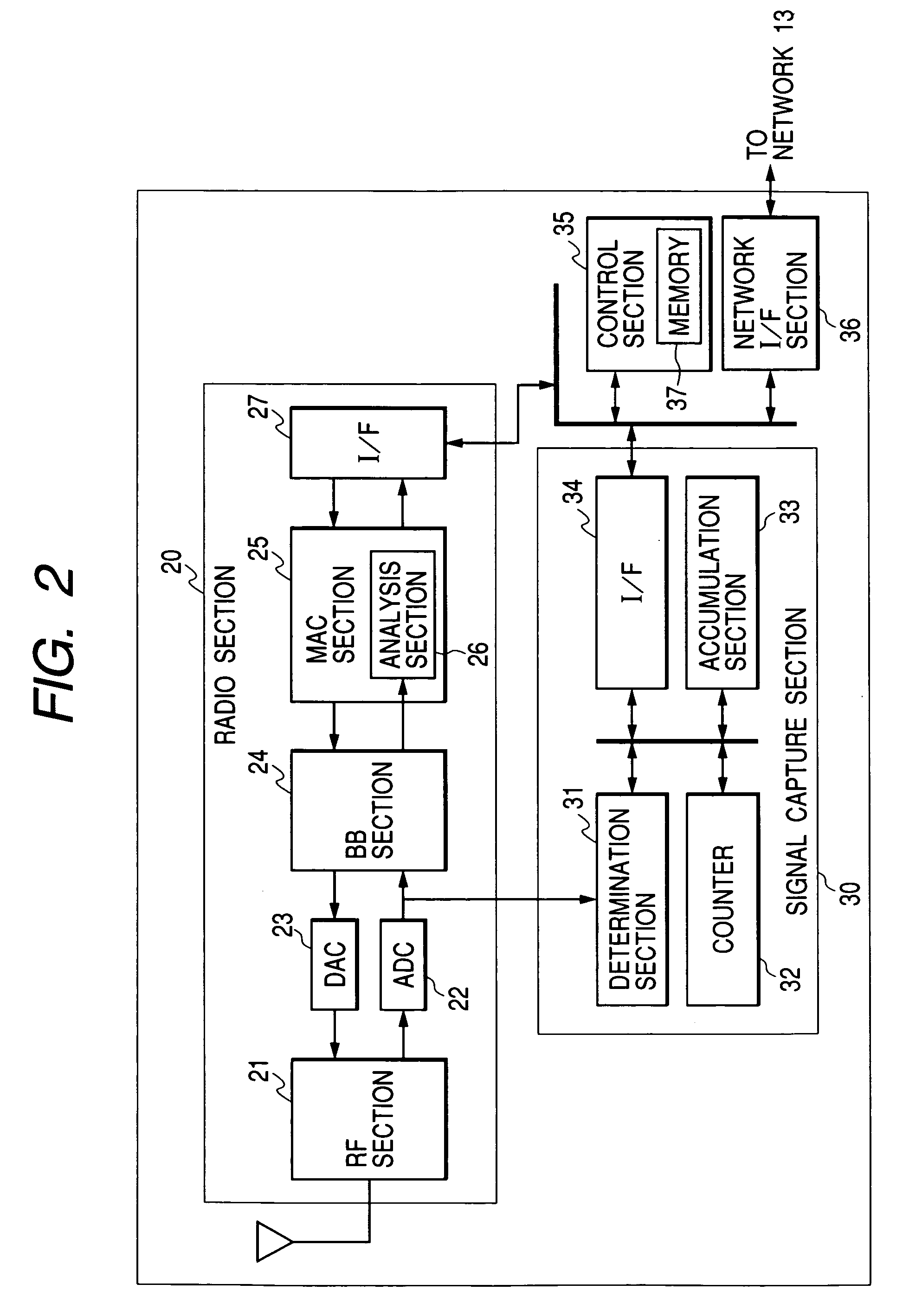

Position calculating method, signal receiver, and position calculating apparatus therefor

InactiveUS6972718B2Avoid positioning accuracyDirection finders using radio wavesPosition fixationMobile stationComputer science

A method of measuring reception timings of signals transmitted and received between base stations and a mobile station and calculating the position of the mobile station by using the reception timings and the reception positions of the signals comprises the steps of obtaining the address information items necessary to specify incoming signals used for the position calculation, analyzing address information items included in the incoming signals, and selecting incoming signals used for position calculation according to a result of comparing the obtained address information items with address information items analyzed in accordance with the incoming signals. A signal incoming from a desired radio station is thus selected and used for position calculation.

Owner:HITACHI LTD

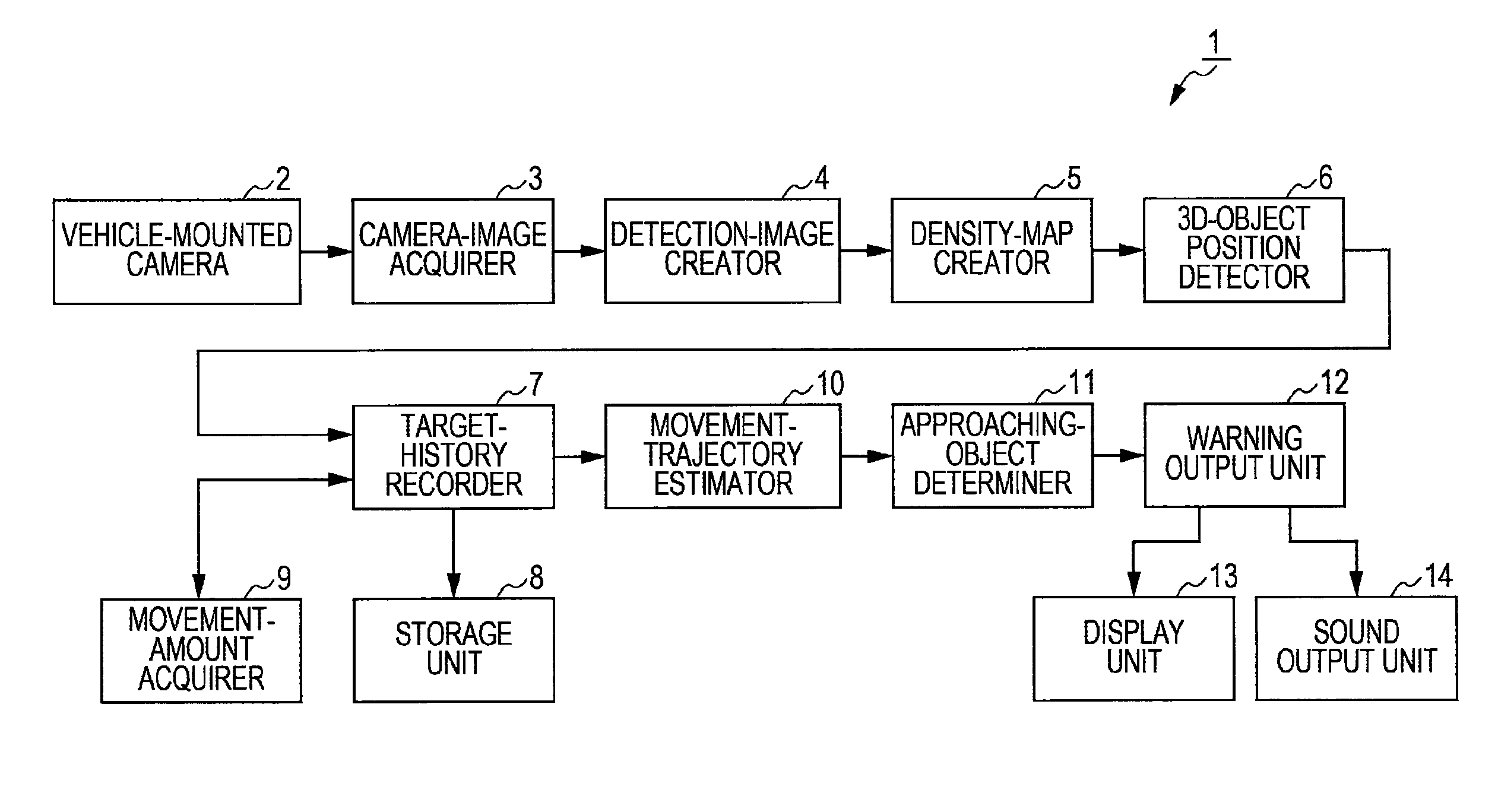

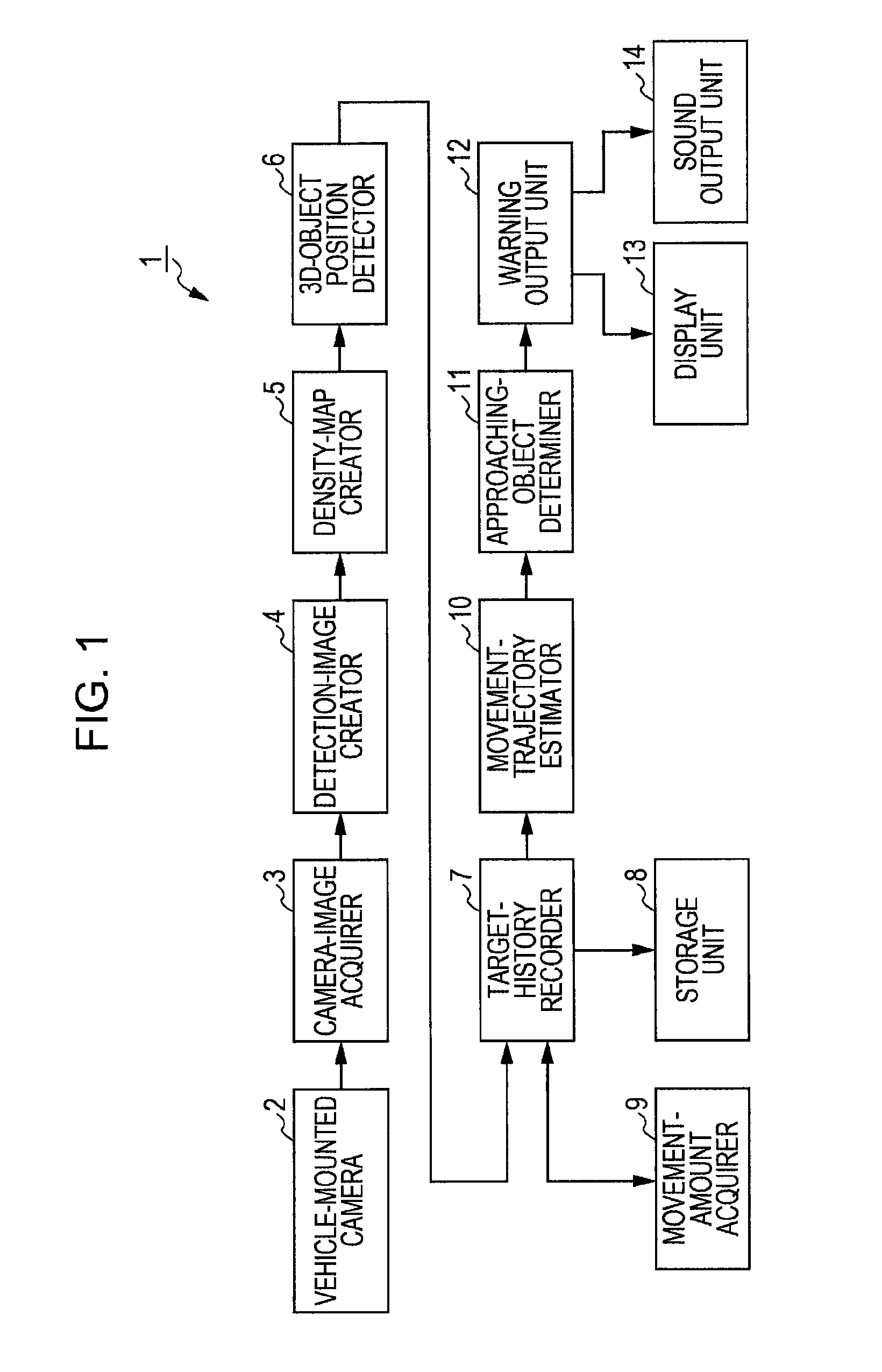

3D object detecting apparatus and 3D object detecting method

ActiveUS8594378B2Simple configurationImprove system reliabilityImage enhancementTelevision system detailsHigh densityComputer graphics (images)

A 3D-object detecting apparatus may include a detection-image creating device configured to detect a 3D object on an image-capture surface from an image captured by an image-capture device and to create a detection image in which a silhouette of only the 3D object is left; a density-map creating device configured to determine the 3D objects spatial densities at corresponding coordinate points in a coordinate plane on the basis of the detection image and mask images obtained for the corresponding coordinate points on the basis of virtual cuboids arranged for the corresponding coordinate points and to create a density map having pixels for the corresponding coordinate points such that the pixels have pixel values corresponding to the determined spatial densities; and a 3D-object position detecting device that detects the position of the 3D object as a representative point in a high-density region in the density map.

Owner:ALPINE ELECTRONICS INC

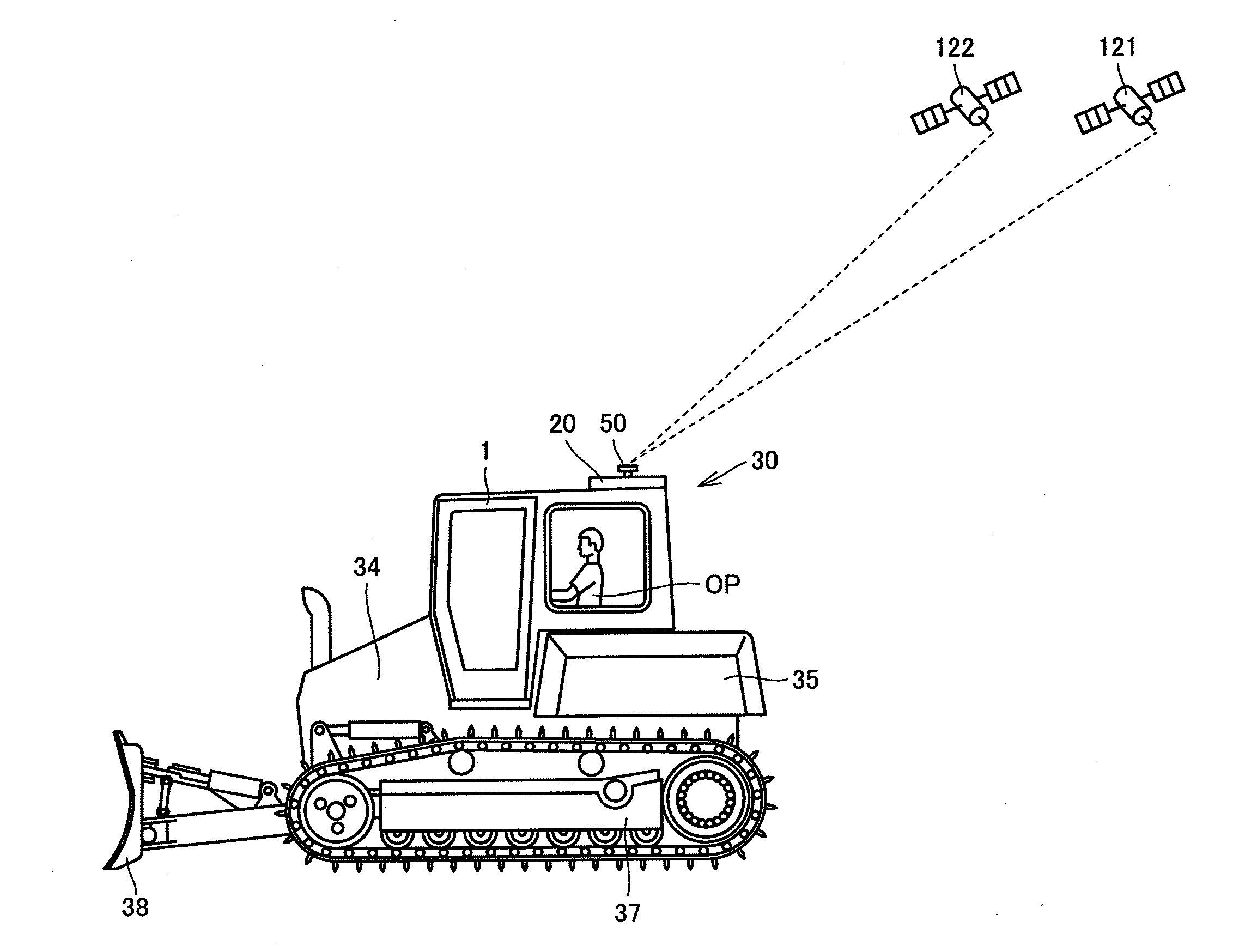

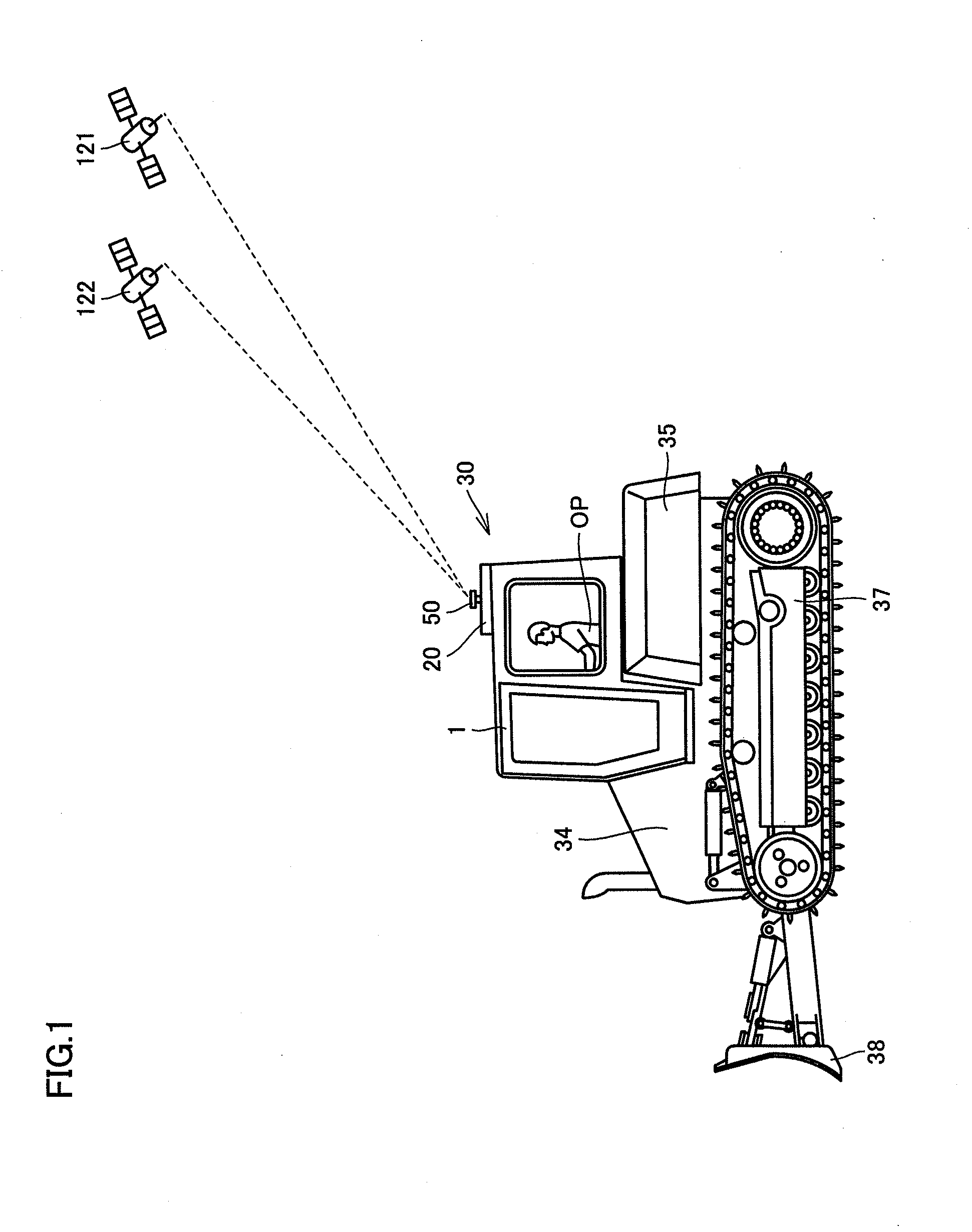

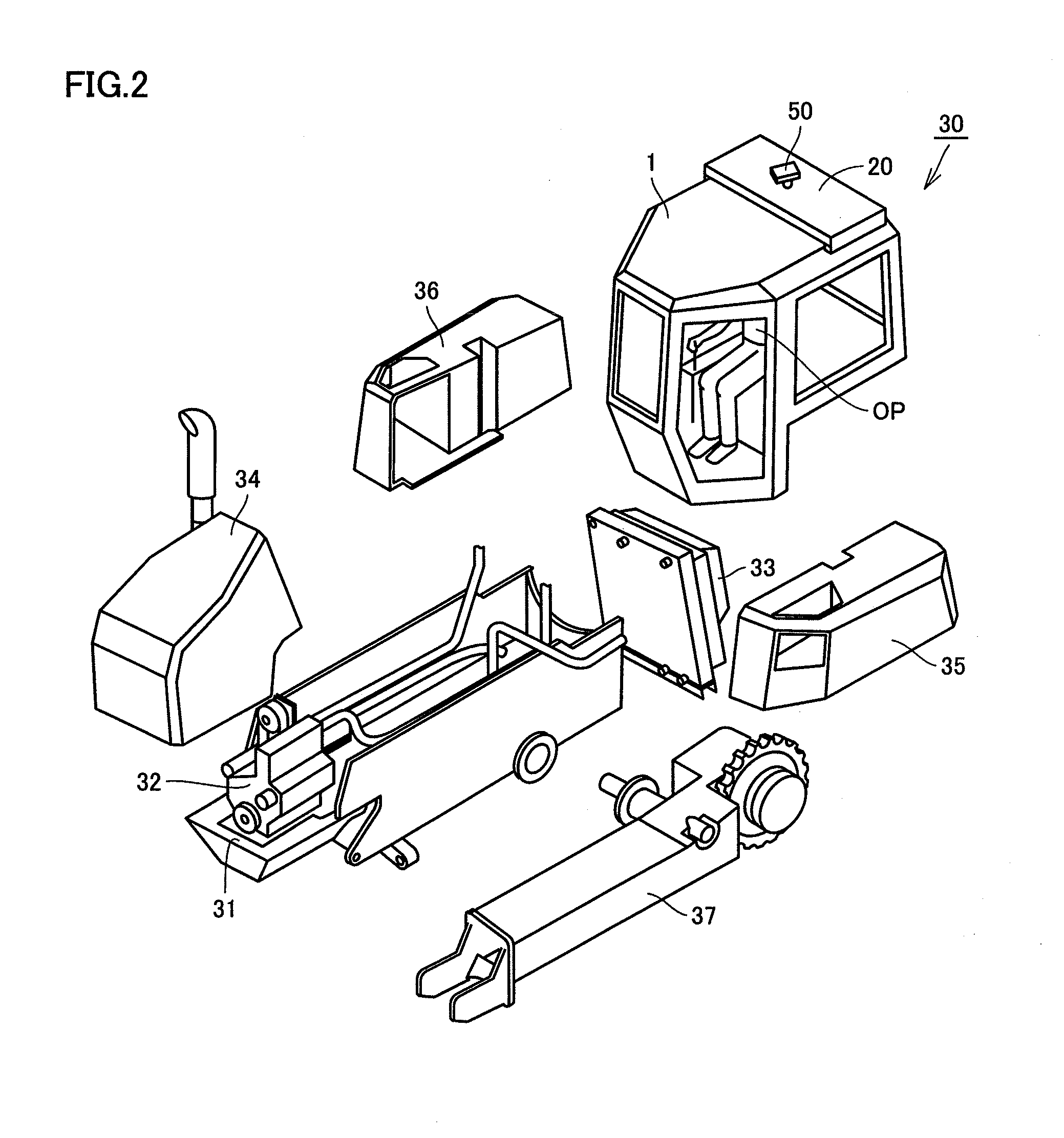

Work vehicle

InactiveUS20140252803A1Avoid positioning accuracyPrecise positioningVehicle seatsSoil-shifting machines/dredgersEngineeringMechanical engineering

Provided is a work vehicle in which a positioning antenna can be installed above a roof plate of a cab at an accurate position and in a proper attitude while preventing a positioning accuracy from being decreased by vibrations. The work vehicle includes a first mount member, a second mount member and a positioning antenna. The first mount member includes a left-side member fixed on the roof beam at the left side and a right-side member fixed on the roof beam at the right side. The second mount member is disposed above the roof plate across the left-side member and the right-side member. The positioning antenna is mounted on the second mount member.

Owner:KOMATSU LTD

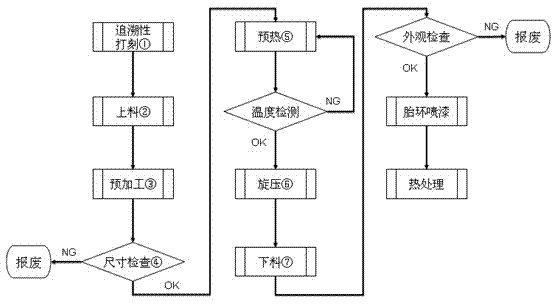

Pre-machining process of spinning hub

The invention relates to a pre-machining process of a spinning hub. After traceable hitting and carving are conducted on a rough material, the rough material is firstly pre-machined, the size of a wheel ring is controlled, and preheating and spinning are conducted. According to the pre-machining process of the spinning hub, mechanical properties of the hub are improved, the thickness of a hub rim can be appropriately reduced, raw materials are saved, production efficiency is promoted, and production cost is lowered. The hub is more accurately positioned on a mold.

Owner:盛旺汽车零部件(昆山)有限公司

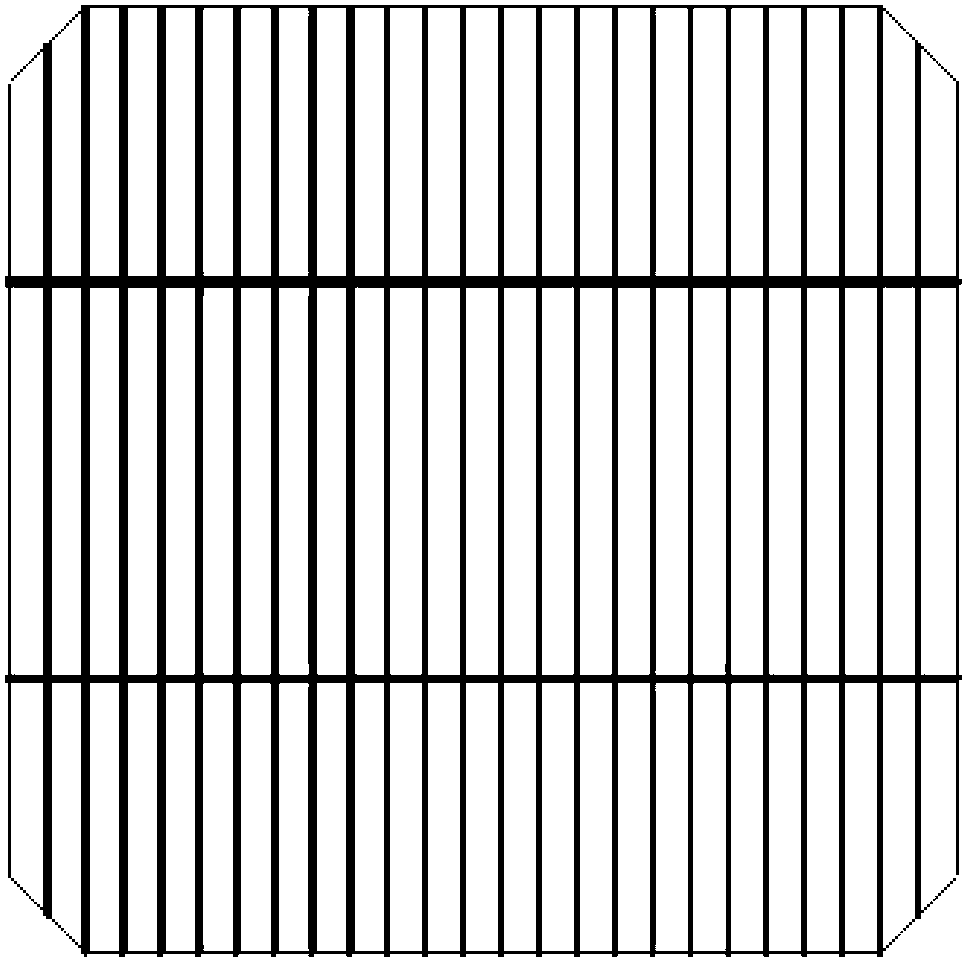

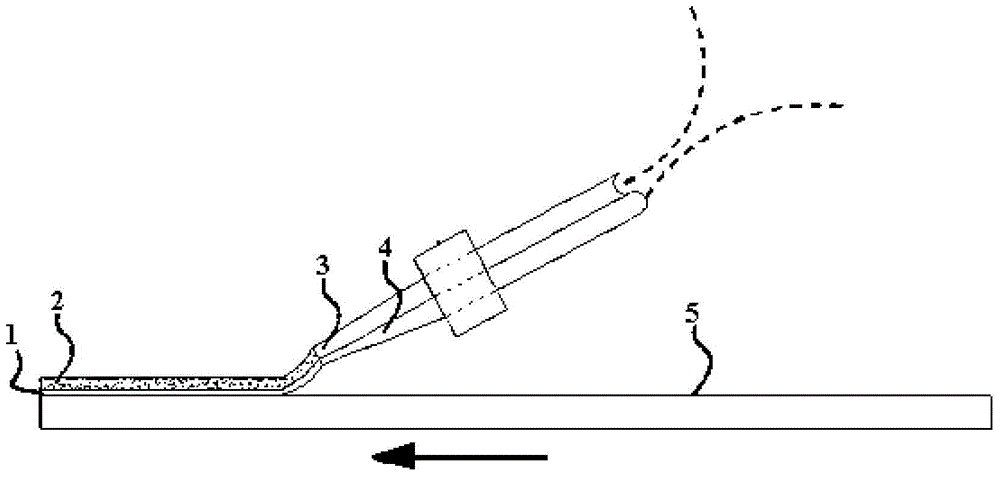

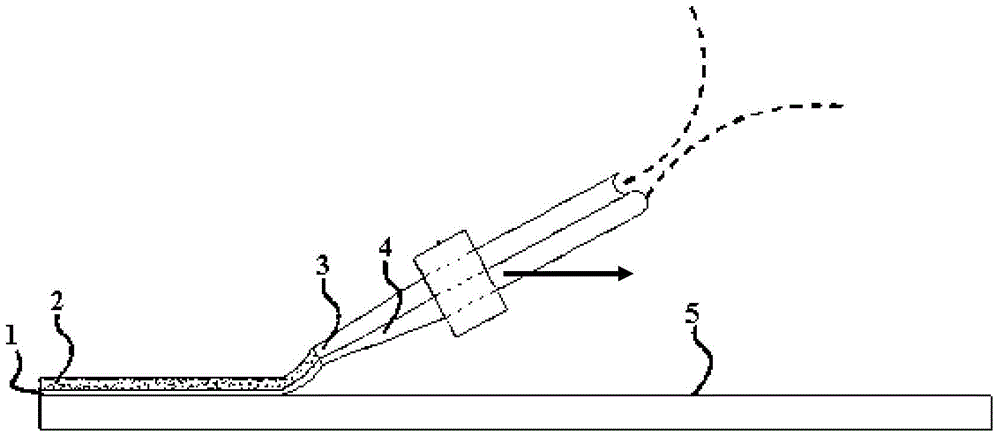

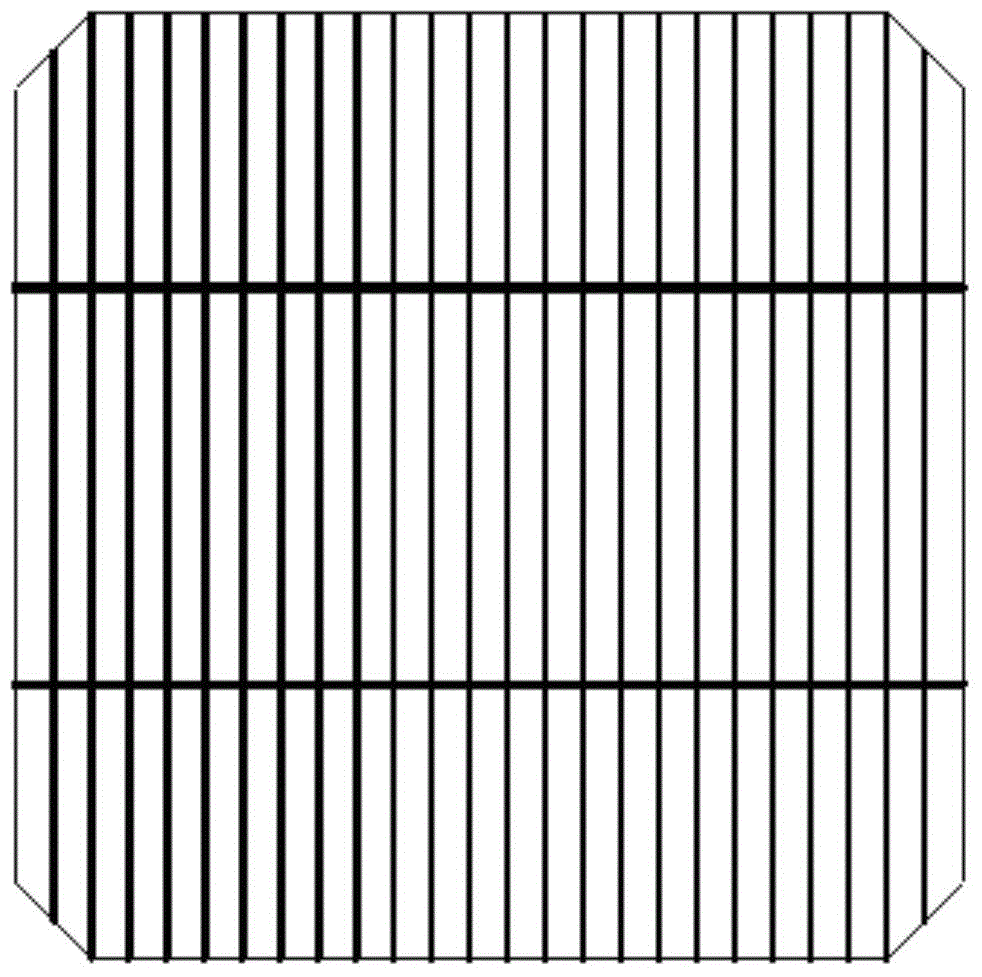

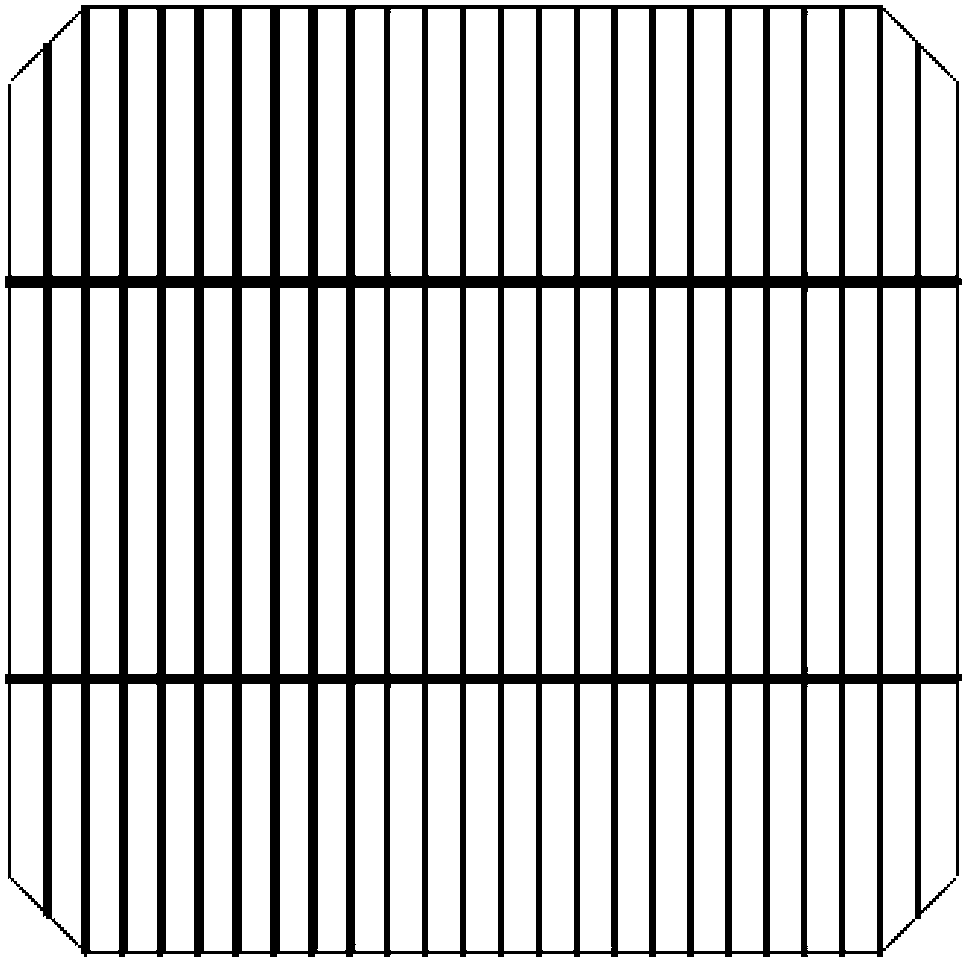

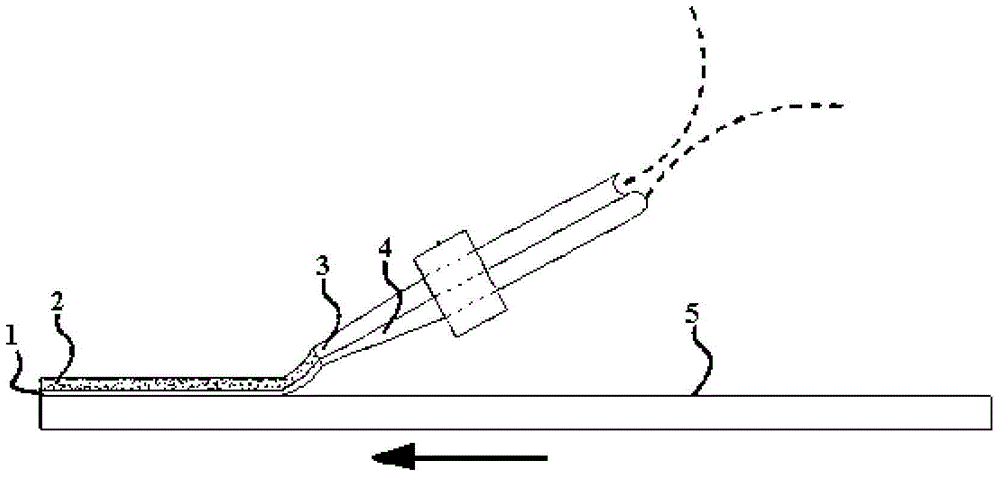

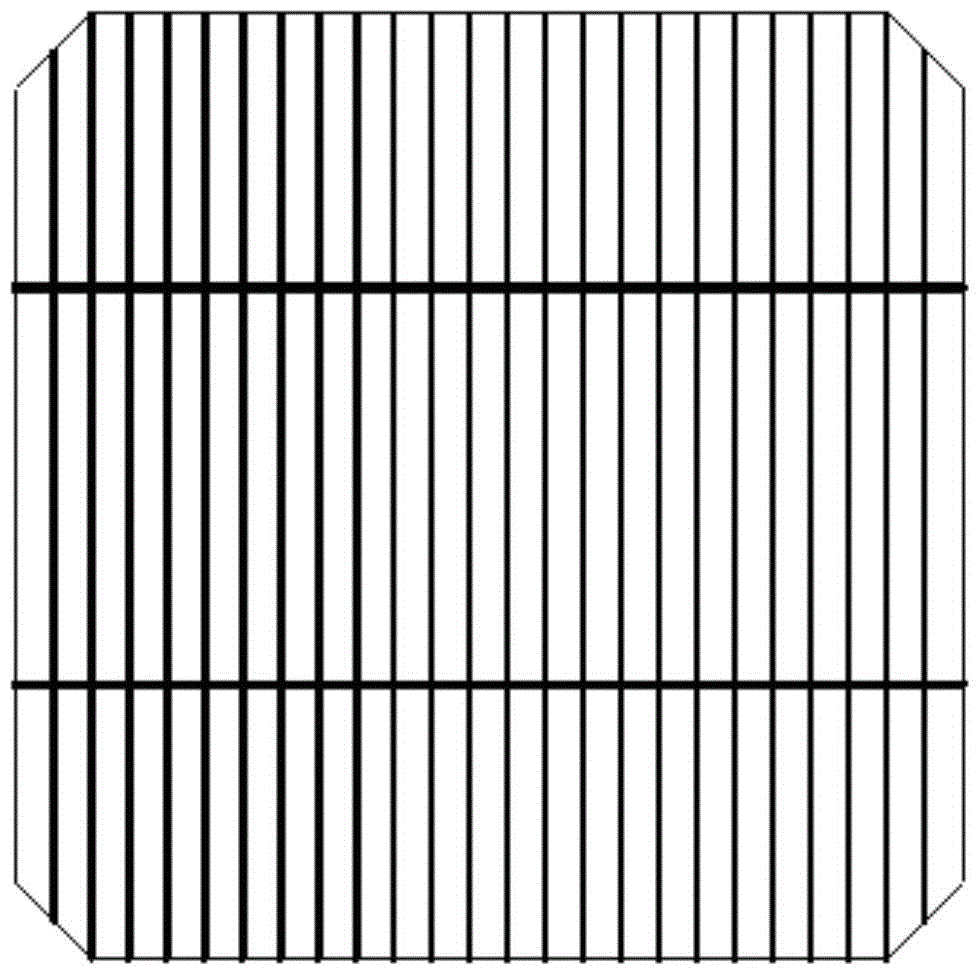

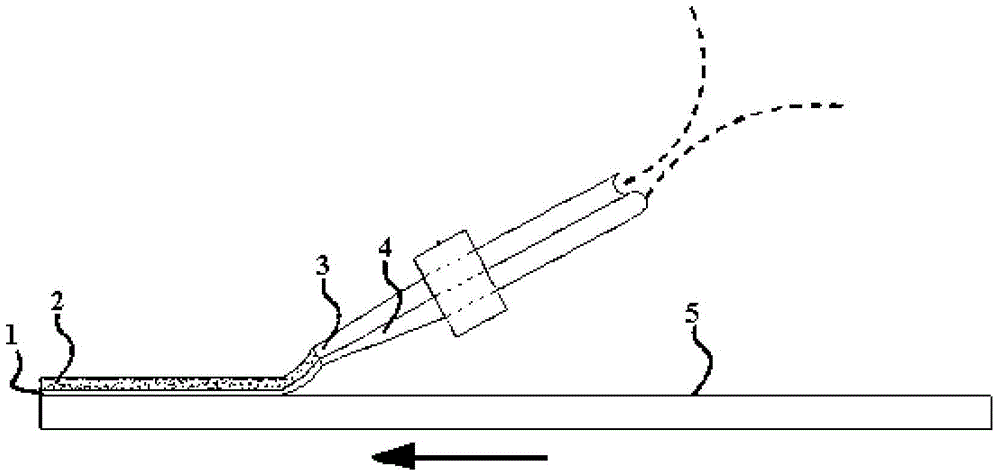

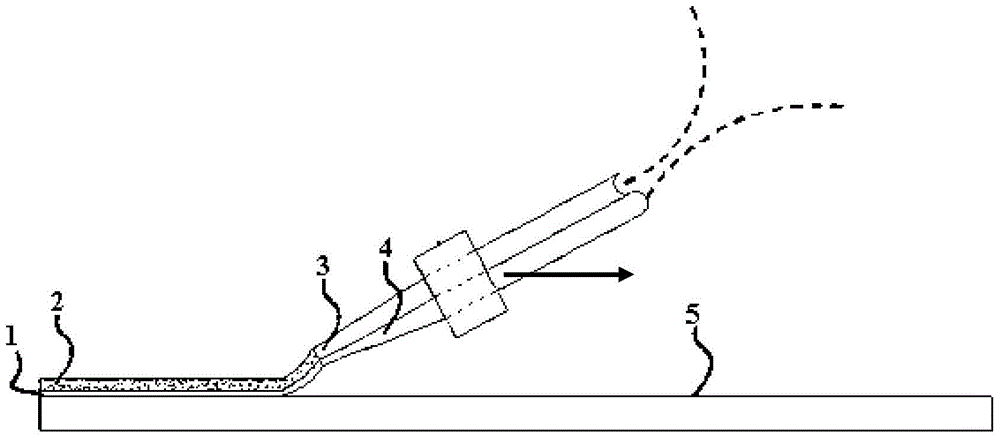

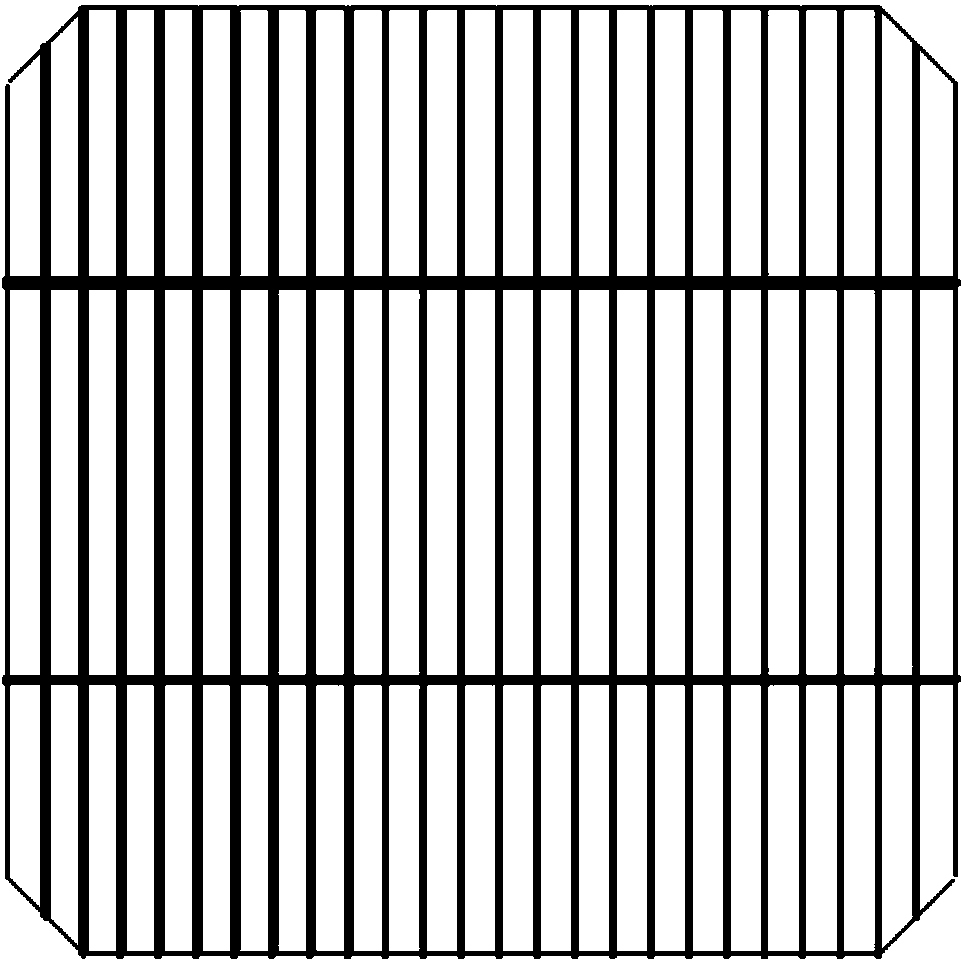

Process for preparing cathode grid line of solar cell

ActiveCN102709394AImprove fire-through abilityEnhanced ohmic contactFinal product manufactureSemiconductor devicesOhmMachining process

The invention discloses a process for preparing a cathode grid line of a solar cell. The cathode grid line of the solar cell consists of a first paste layer and a second paste layer positioned on the upper surface of the first paste layer. First paste and second paste are loaded into containers which are connected with a lower nozzle and an upper nozzle respectively. The upper and lower nozzles are tightly attached and arranged in parallel, and the lower nozzle is positioned on the upper lateral surface of the upper nozzle. The spray coating pressure of the lower nozzle is 0.5MPa, and the spray coating pressure of the upper nozzle is 0.65MPa. The travel speed of the lower and upper nozzles is 125mm / s. The first paste consists of an organic carrier, silver powder, glass powder and an ohm contact additive. The second paste consists of an organic carrier, silver powder, glass powder and a metallic-phase adhesive. A high-aspect ratio cathode of the solar cell can be prepared, and a problem about positioning accuracy is solved; and in addition, requirements for a cathode shape and electrical conductivity can be met, and silicon chip fragmentation caused by pressure applied to a silicon chip in a machining process can be avoided.

Owner:SUZHOU ISILVER MATERIALS

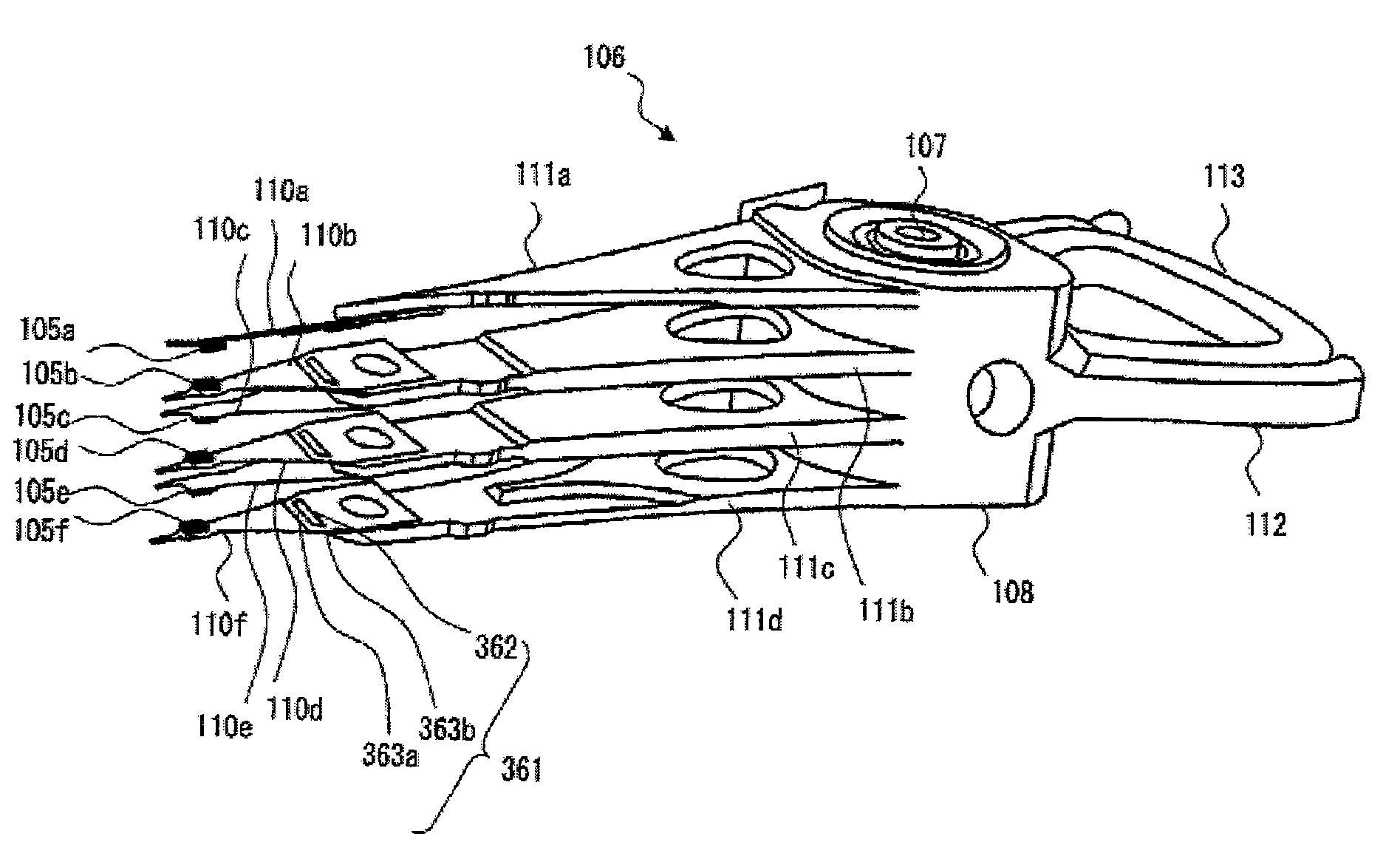

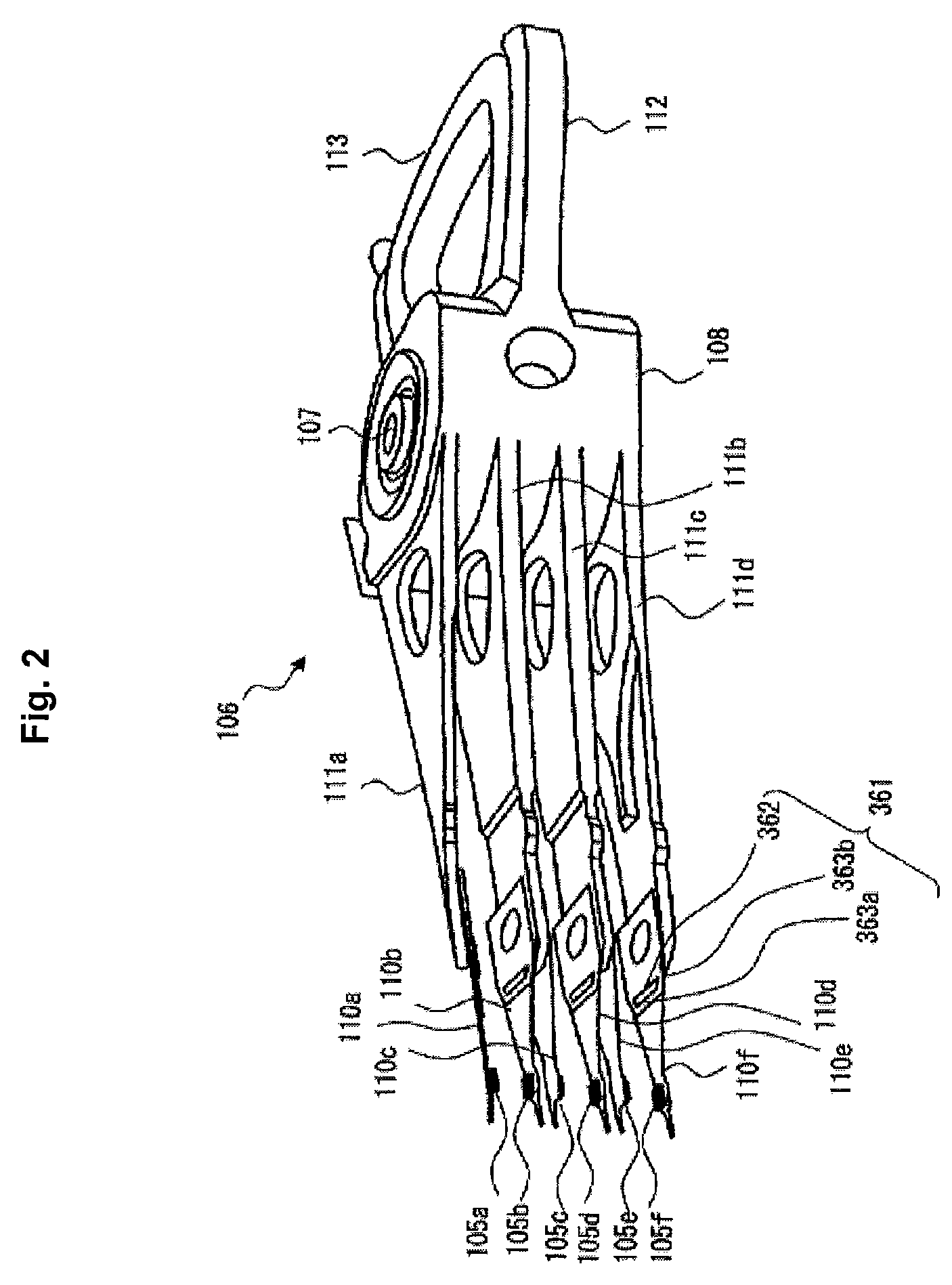

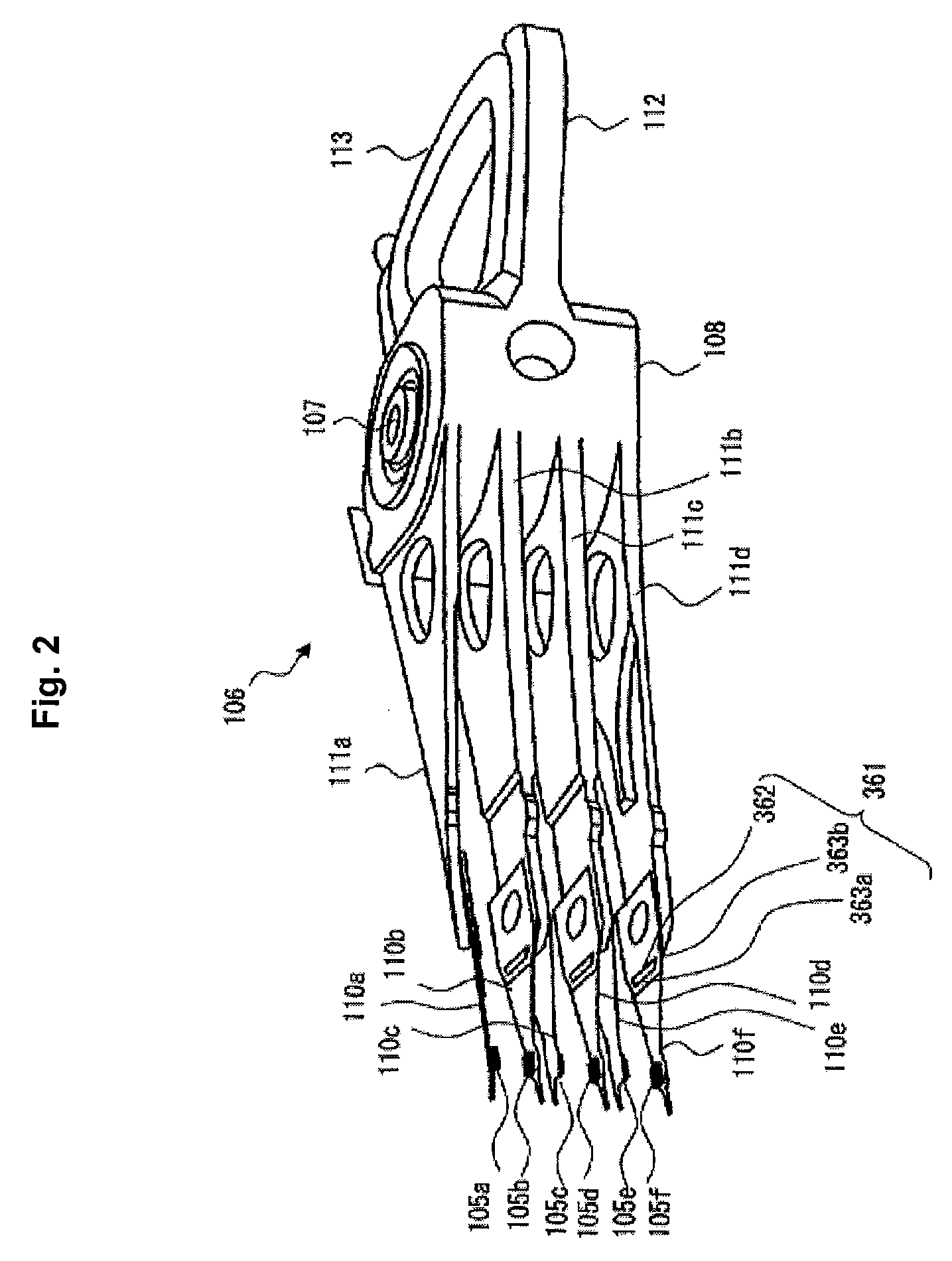

Disk drive apparatus and head assembly used for the same

InactiveUS7855857B2Reduce the valueAvoid positioning accuracyDisposition/mounting of recording headsRecord information storageSkew anglePeak value

Owner:WESTERN DIGITAL TECH INC

Disk drive apparatus and head assembly used for the same

InactiveUS20080007862A1Reduce off-track valueReduce the valueDisposition/mounting of recording headsRecord information storageHead positionPeak value

Embodiments of the present invention restrain the head position accuracy from degrading due to torsional vibration of a head supporting unit. According to an embodiment of the invention, an actuator has a twisted carriage arm. A suspension is tilted in accordance with the twist of the carriage arm. When the carriage arm and the suspension torsionally vibrate, the vibration direction tilts against the normal direction of a recording surface in accordance with the twist. This technique decreases a peak value of off-track displacement that is caused by a head slider and is dependent on relationship between a skew angle and a torsional vibration direction.

Owner:WESTERN DIGITAL TECH INC

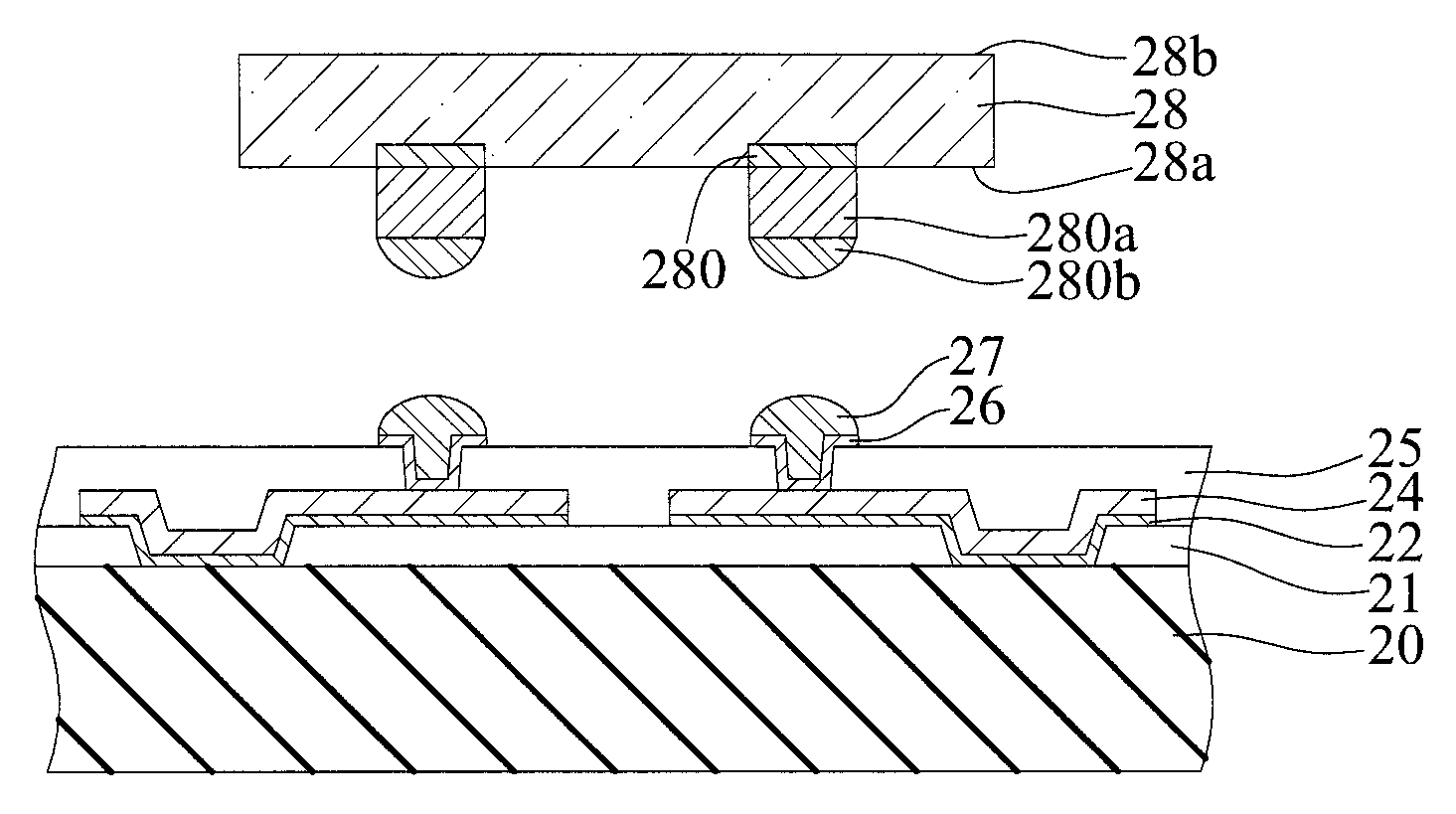

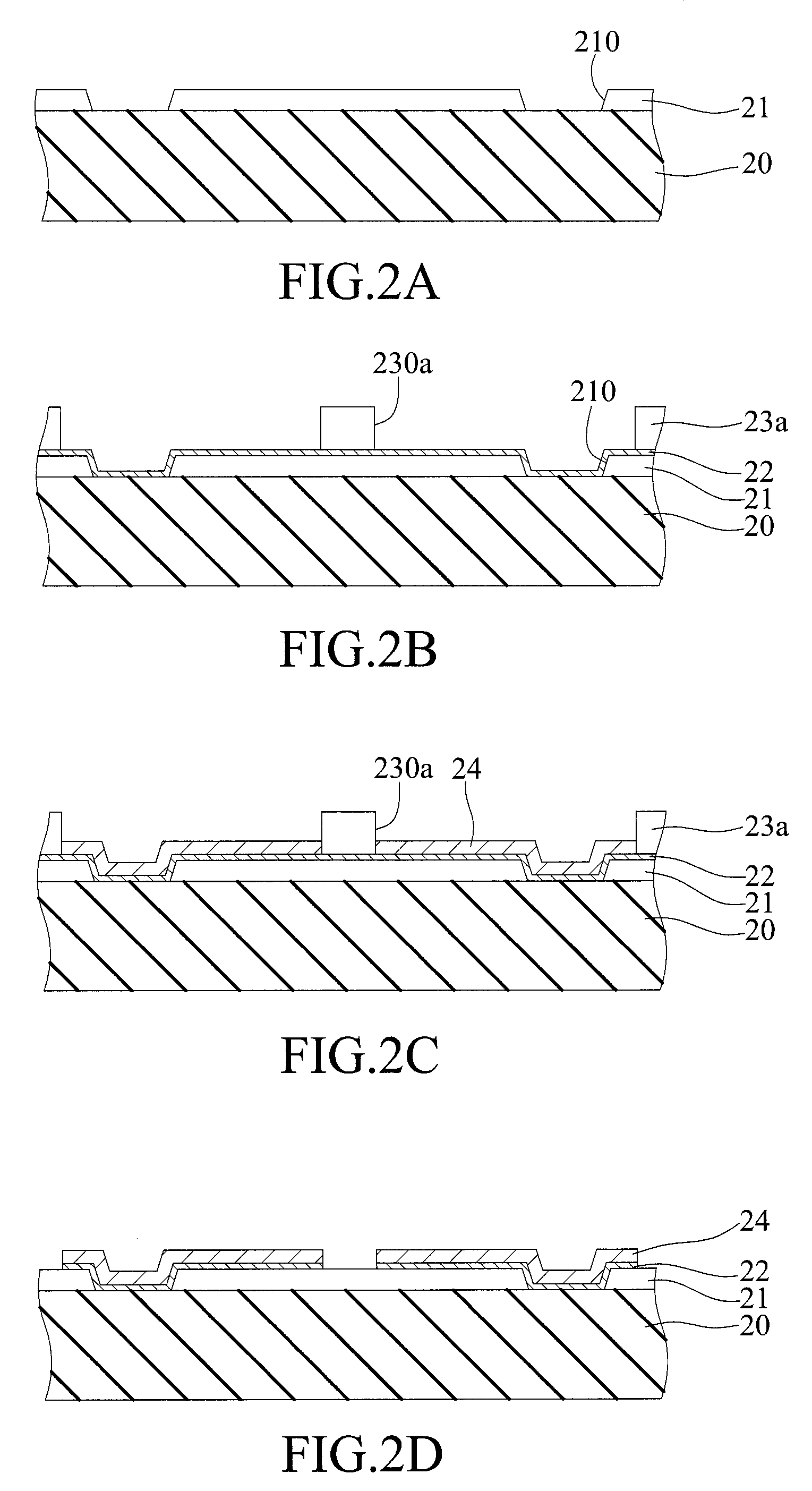

Fabrication method of wafer level semiconductor package and fabrication method of wafer level packaging substrate

ActiveUS9269602B2Easy to controlAvoid positioning accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor packageDielectric layer

Owner:SILICONWARE PRECISION IND CO LTD

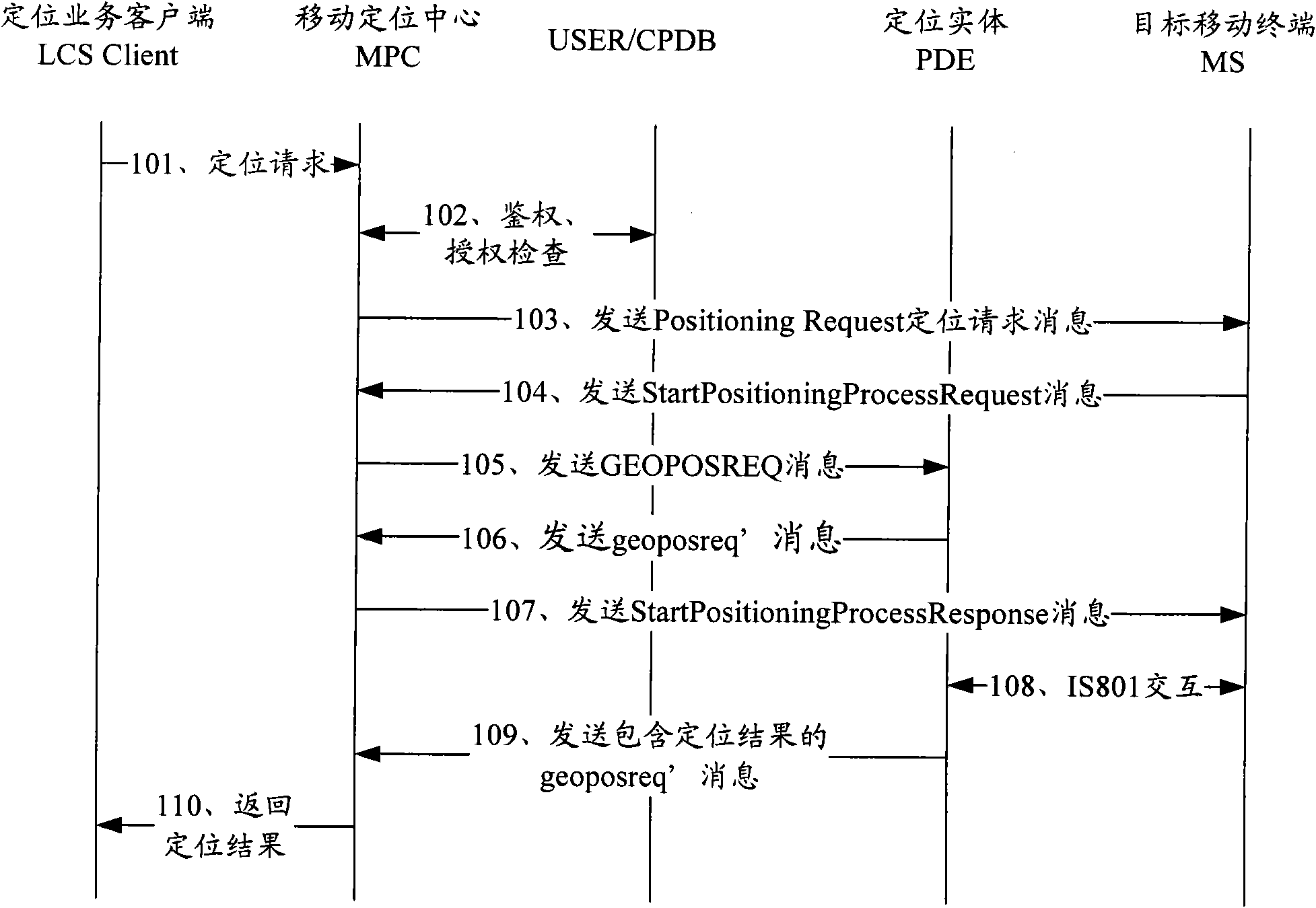

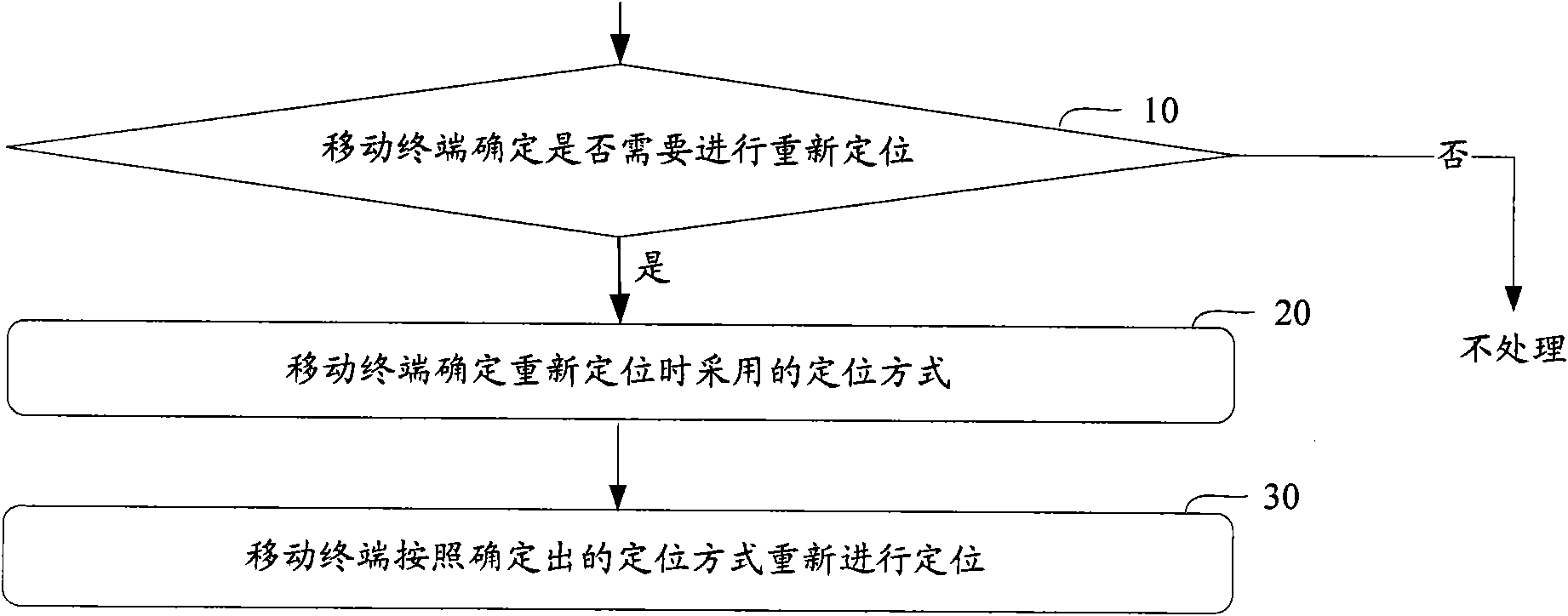

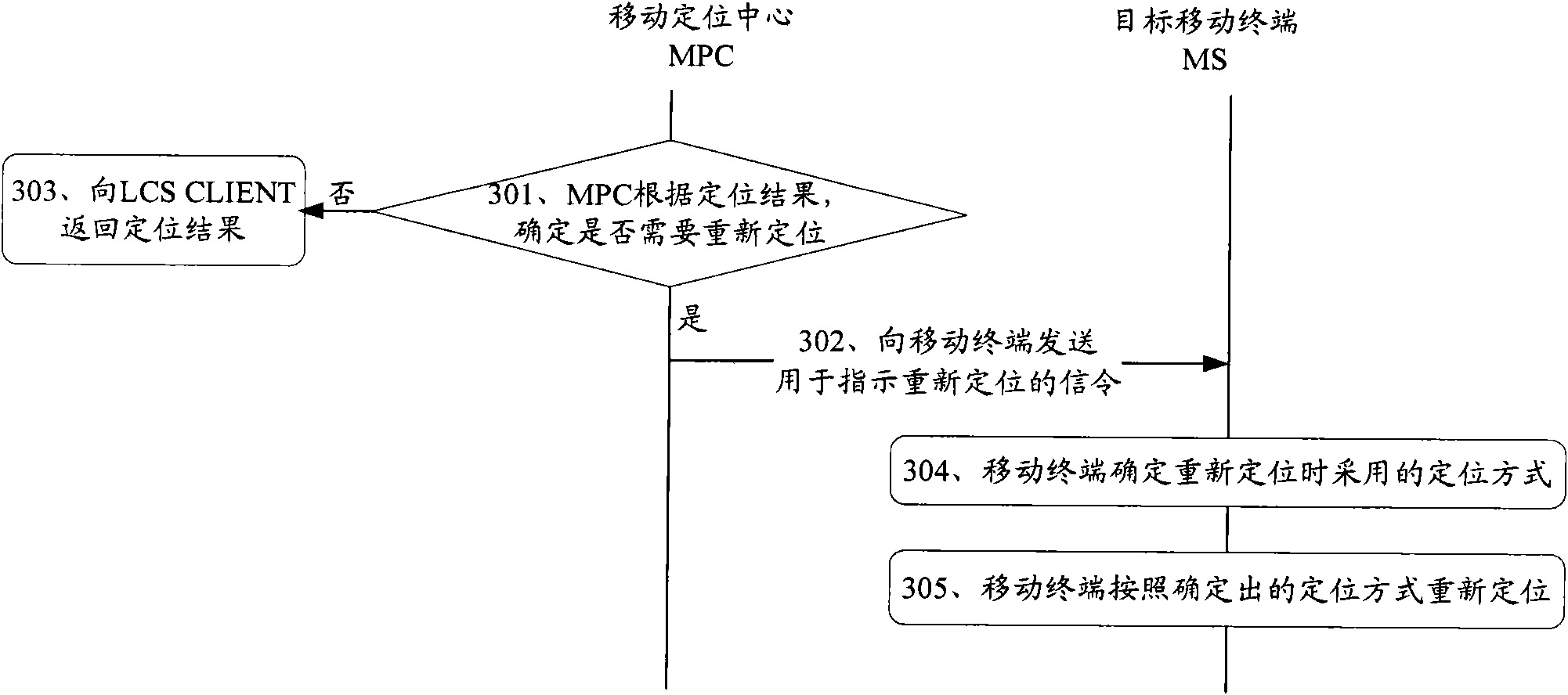

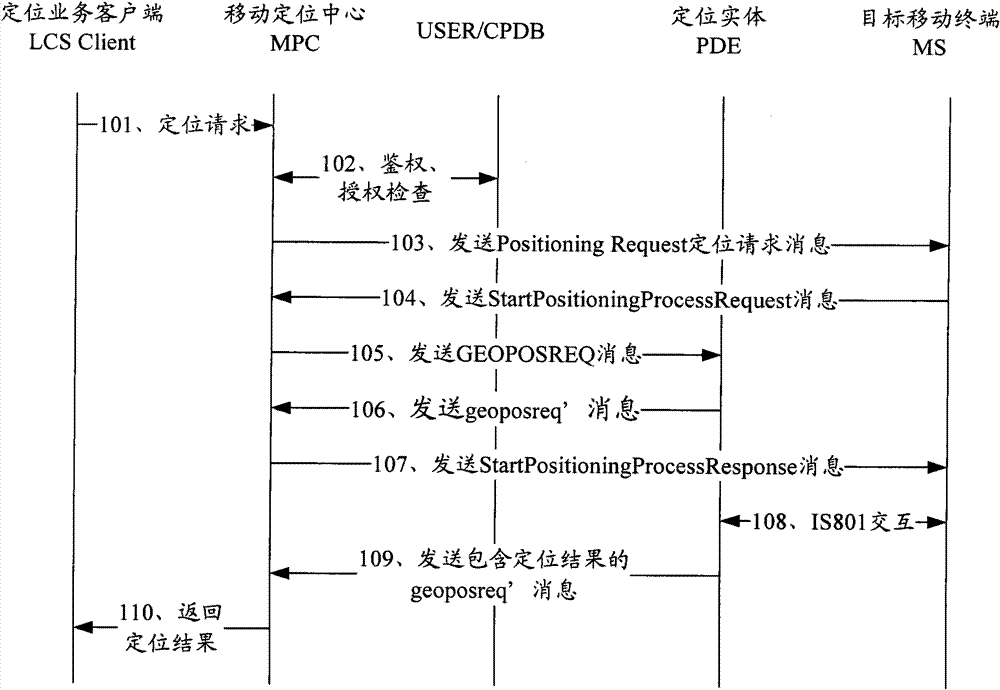

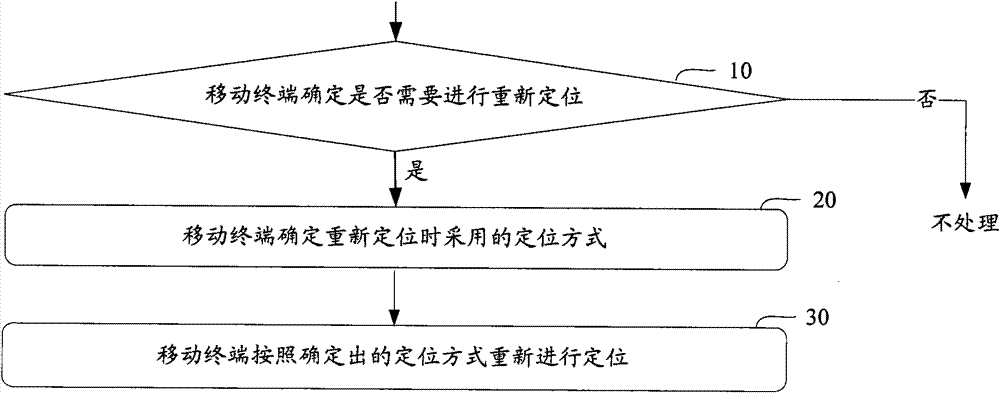

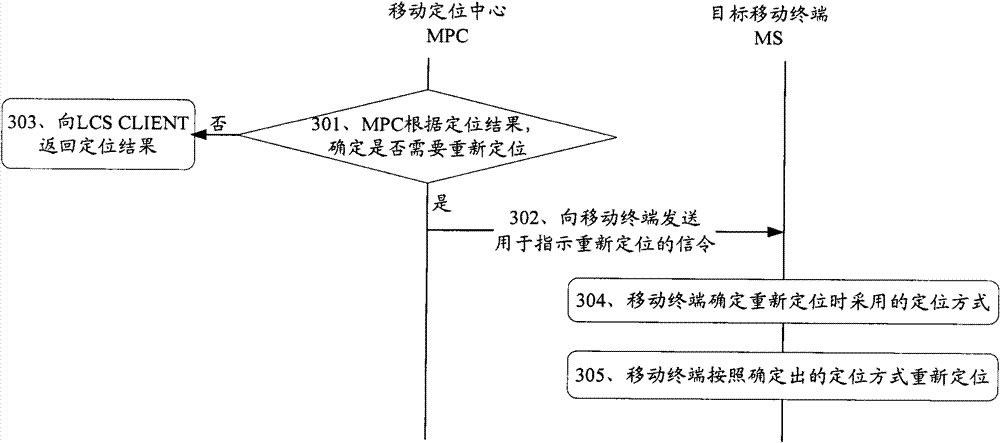

Locating method of mobile terminal and related device

ActiveCN101784007AAvoid positioning reliabilityAvoid positioning accuracyLocation information based serviceDependabilityComputer science

The invention discloses a locating method of a mobile terminal and a related device, aiming at solving the problems of lower reliability or accuracy in the existing location technology. The method comprises the steps of: confirming a locating way adopted by relocation when relocation is determined to be carried out by the mobile terminal; and carrying out relocation according to the confirmed locating way.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Lens unit and lens driving apparatus

InactiveUS8300331B2Avoid positioning accuracyDisplacement stabilityProjector focusing arrangementCamera focusing arrangementCamera lensEngineering

Owner:SHARP KK

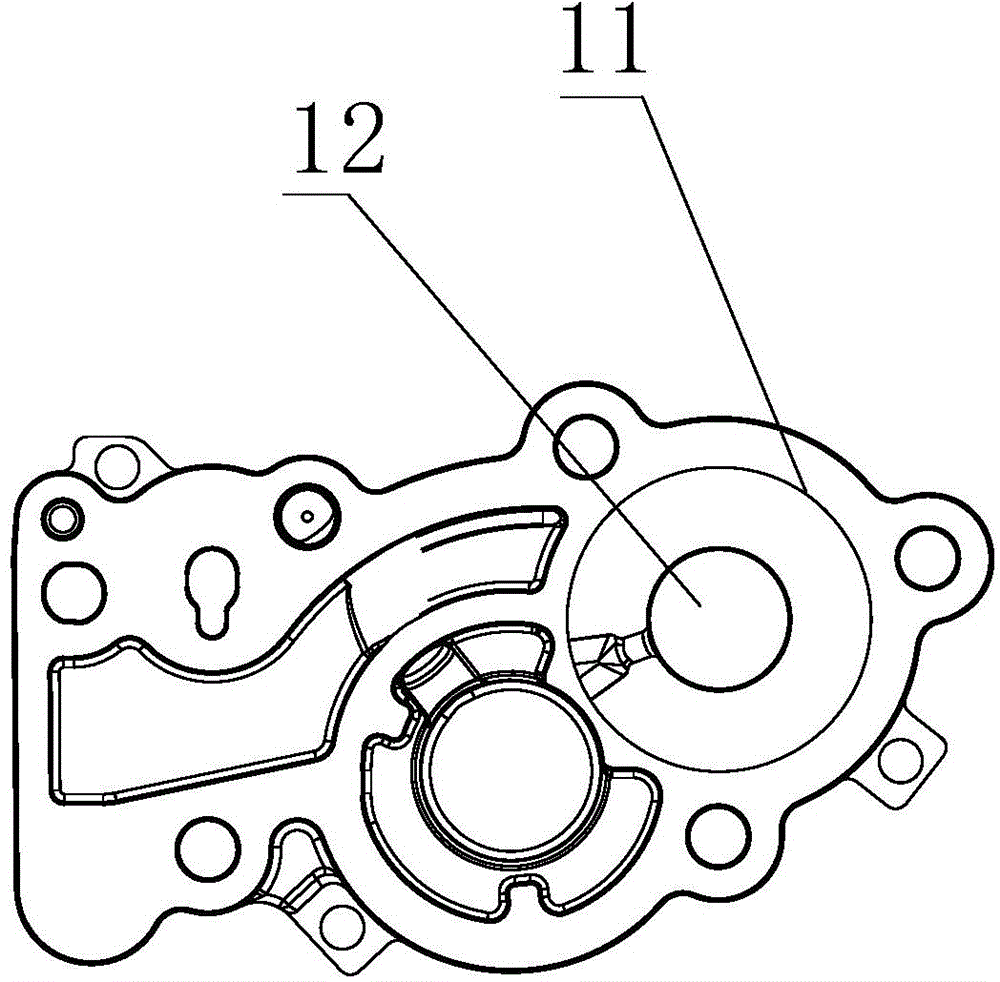

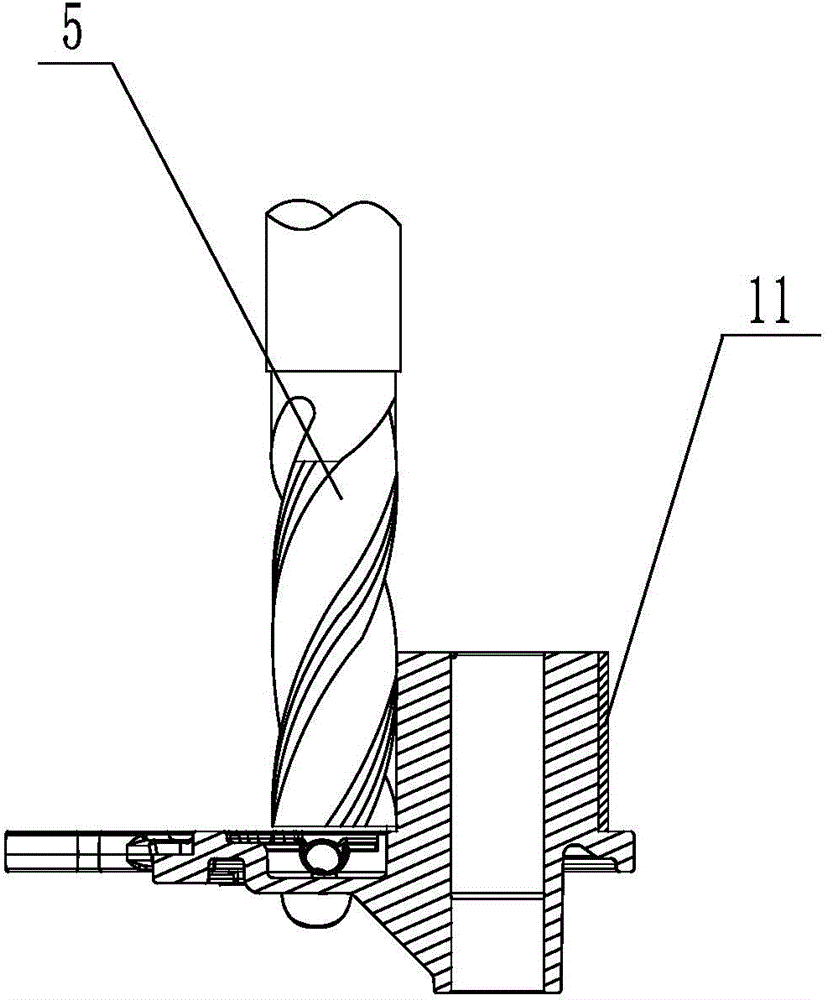

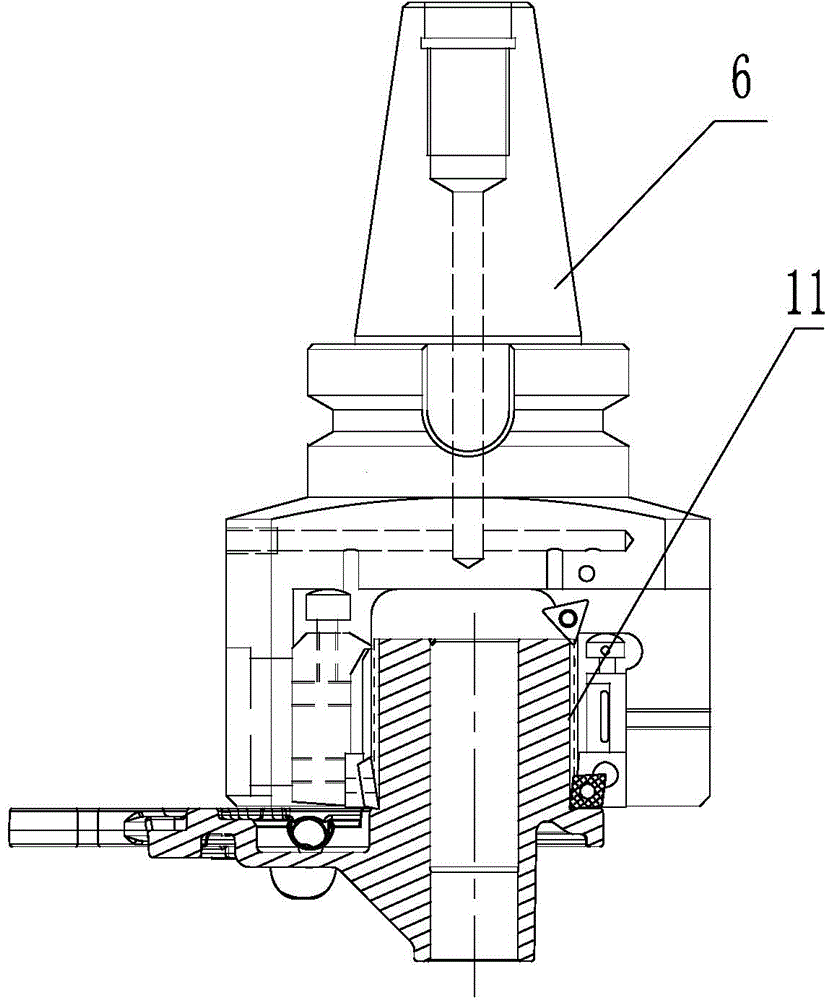

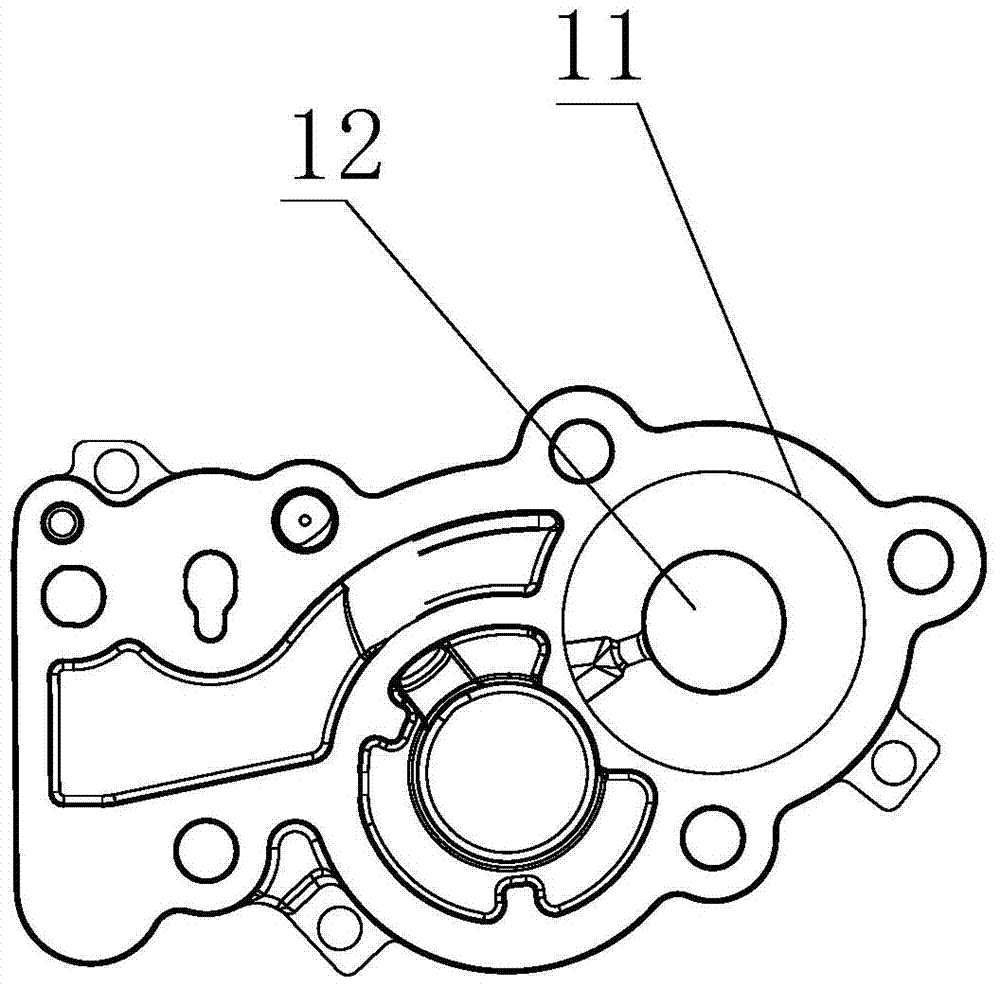

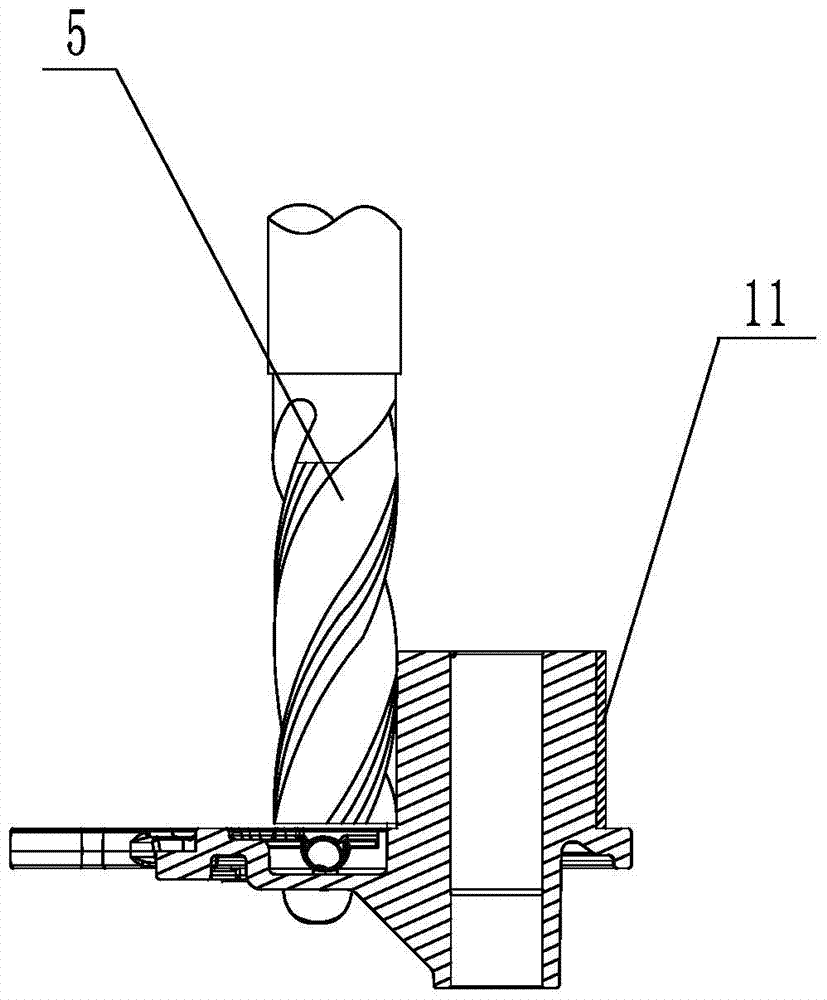

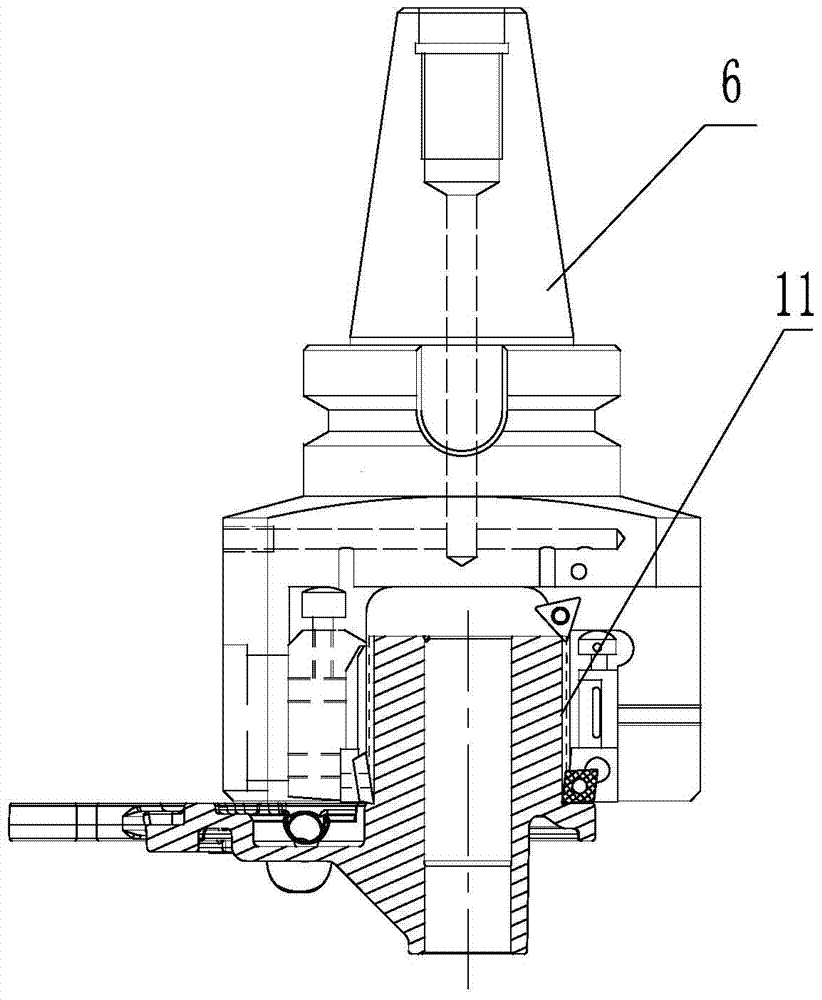

Variable oil pump cover machining method

ActiveCN104999220AAvoid positioning accuracyHigh positioning accuracyLubricating pumpsEngineeringMachining time

The invention provides a variable oil pump cover machining method. The variable oil pump cover machining method comprises the following steps: (A) a pump cover to be machined is positioned on a rotating support plate through a positioning fixture; and firstly, the support plate is in a horizontal state; (B) the frontal surface of the pump cover is roughly machined; and the machining contents comprise rough milling of a shaft side plane, milling of a shaft end surface and a cover plane and drilling of a shaft hole and a hole orifice chambering angle; (C) the frontal surface of the pump cover is finely machined; and the machining contents comprise coating and turning of the shaft side plane and finish boring of the shaft hole; (D) the support plate rotates to be positioned in a direction of 15 degrees; and (E) an inclined oil hole in the inclined surface of the pump cover is drilled. The method is high in machining precision and short in machining time.

Owner:华域皮尔博格泵技术有限公司

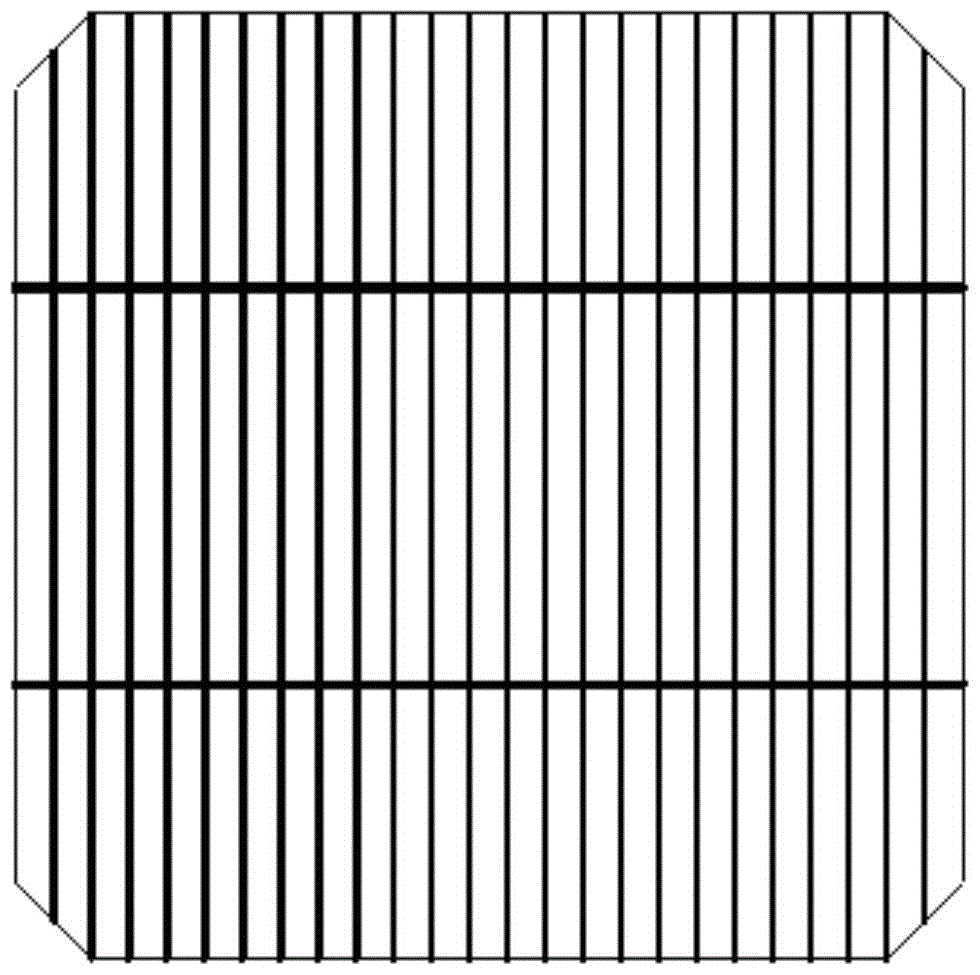

Method for manufacturing solar cell grid line

ActiveCN104377272AImprove fire-through abilityEnhanced ohmic contactFinal product manufactureNon-conductive material with dispersed conductive materialWidth ratioMicrometer

The invention discloses a method for manufacturing a solar cell grid line. The grid line of a front electrode of a cell comprises a first slurry layer and a second slurry layer located on the upper surface of the first slurry layer. First slurry comprises an organic carrier, silver powder, glass powder and an ohm contact additive. Second slurry comprises an organic carrier, silver powder, glass powder and a metal adhesive. The organic carrier in the second slurry is formed by heating terpilenol, butyl carbitol, ethyl cellulose and the balance in the proportion of 53:28:14:5 to 60 DEG C, stirring for at least two hours and mixing the components. The particle size of the silver powder is 6 micrometers, and the glass powder is made of bismuth, silicon and antimony. The front electrode of the solar cell with a high height-width ratio can be manufactured through the manufacturing method, the problem of positioning precision is solved, burning ability of an anti-reflection layer is improved, and adhesion force of the electrode to a cell substrate is improved.

Owner:SUZHOU ISILVER MATERIALS

Process for preparing cathode grid line of solar cell

ActiveCN102709394BAvoid positioning accuracyMeet the requirements of the contact interfaceFinal product manufactureSemiconductor devicesAdhesiveSpray coating

The invention discloses a process for preparing a cathode grid line of a solar cell. The cathode grid line of the solar cell consists of a first paste layer and a second paste layer positioned on the upper surface of the first paste layer. First paste and second paste are loaded into containers which are connected with a lower nozzle and an upper nozzle respectively. The upper and lower nozzles are tightly attached and arranged in parallel, and the lower nozzle is positioned on the upper lateral surface of the upper nozzle. The spray coating pressure of the lower nozzle is 0.5MPa, and the spray coating pressure of the upper nozzle is 0.65MPa. The travel speed of the lower and upper nozzles is 125mm / s. The first paste consists of an organic carrier, silver powder, glass powder and an ohm contact additive. The second paste consists of an organic carrier, silver powder, glass powder and a metallic-phase adhesive. A high-aspect ratio cathode of the solar cell can be prepared, and a problem about positioning accuracy is solved; and in addition, requirements for a cathode shape and electrical conductivity can be met, and silicon chip fragmentation caused by pressure applied to a silicon chip in a machining process can be avoided.

Owner:SUZHOU ISILVER MATERIALS

Image recording apparatus

ActiveUS9580265B2Reduce positioningPositional inaccuracy in the membersArticle feedersArticle deliveryDrive shaftImage recording

An image recording apparatus, including a tray configured to support a sheet; a chassis defining a first conveyer path, in which the sheet on the tray is conveyed in a first conveying direction, and a second conveyer path, through which the sheet is conveyed in a second conveying direction through a branch point to be inverted to reenter the first conveyer path through a merging point; a base member integrally formed of resin and including a guiding section to define a form of a part of the second conveyer path; a recording unit to record an image on the sheet conveyed in the first conveyer path; a drive shaft supported by the base member; and a return-conveyer roller disposed in the second conveyer path and configured to convey the sheet to be guided on the guiding section in the second conveying direction by rotation of the drive shaft, is provided.

Owner:BROTHER KOGYO KK

Manufacturing method of solar cell grid wire

ActiveCN104377272BAvoid positioning accuracyMeet the requirements of the contact interfaceFinal product manufactureNon-conductive material with dispersed conductive materialAdhesiveSlurry

The invention discloses a method for manufacturing a solar cell grid line. The grid line of a front electrode of a cell comprises a first slurry layer and a second slurry layer located on the upper surface of the first slurry layer. First slurry comprises an organic carrier, silver powder, glass powder and an ohm contact additive. Second slurry comprises an organic carrier, silver powder, glass powder and a metal adhesive. The organic carrier in the second slurry is formed by heating terpilenol, butyl carbitol, ethyl cellulose and the balance in the proportion of 53:28:14:5 to 60 DEG C, stirring for at least two hours and mixing the components. The particle size of the silver powder is 6 micrometers, and the glass powder is made of bismuth, silicon and antimony. The front electrode of the solar cell with a high height-width ratio can be manufactured through the manufacturing method, the problem of positioning precision is solved, burning ability of an anti-reflection layer is improved, and adhesion force of the electrode to a cell substrate is improved.

Owner:SUZHOU ISILVER MATERIALS

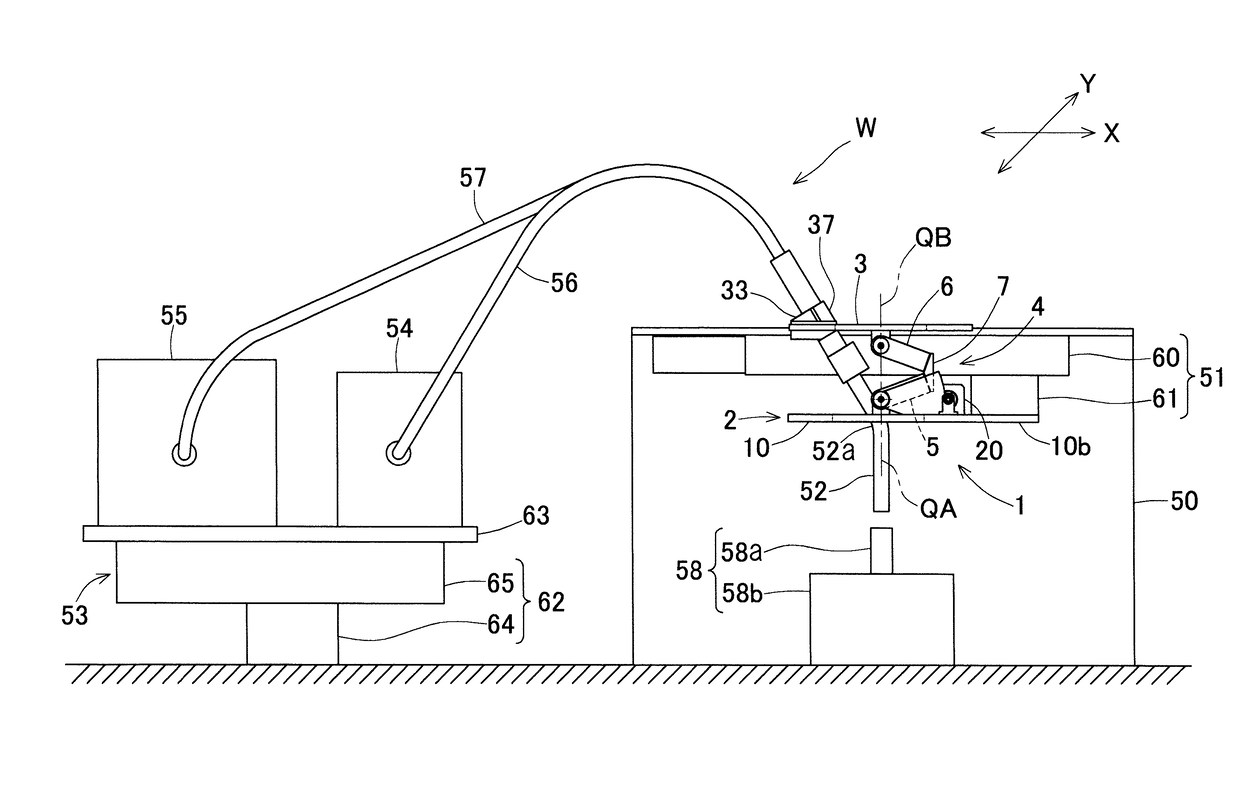

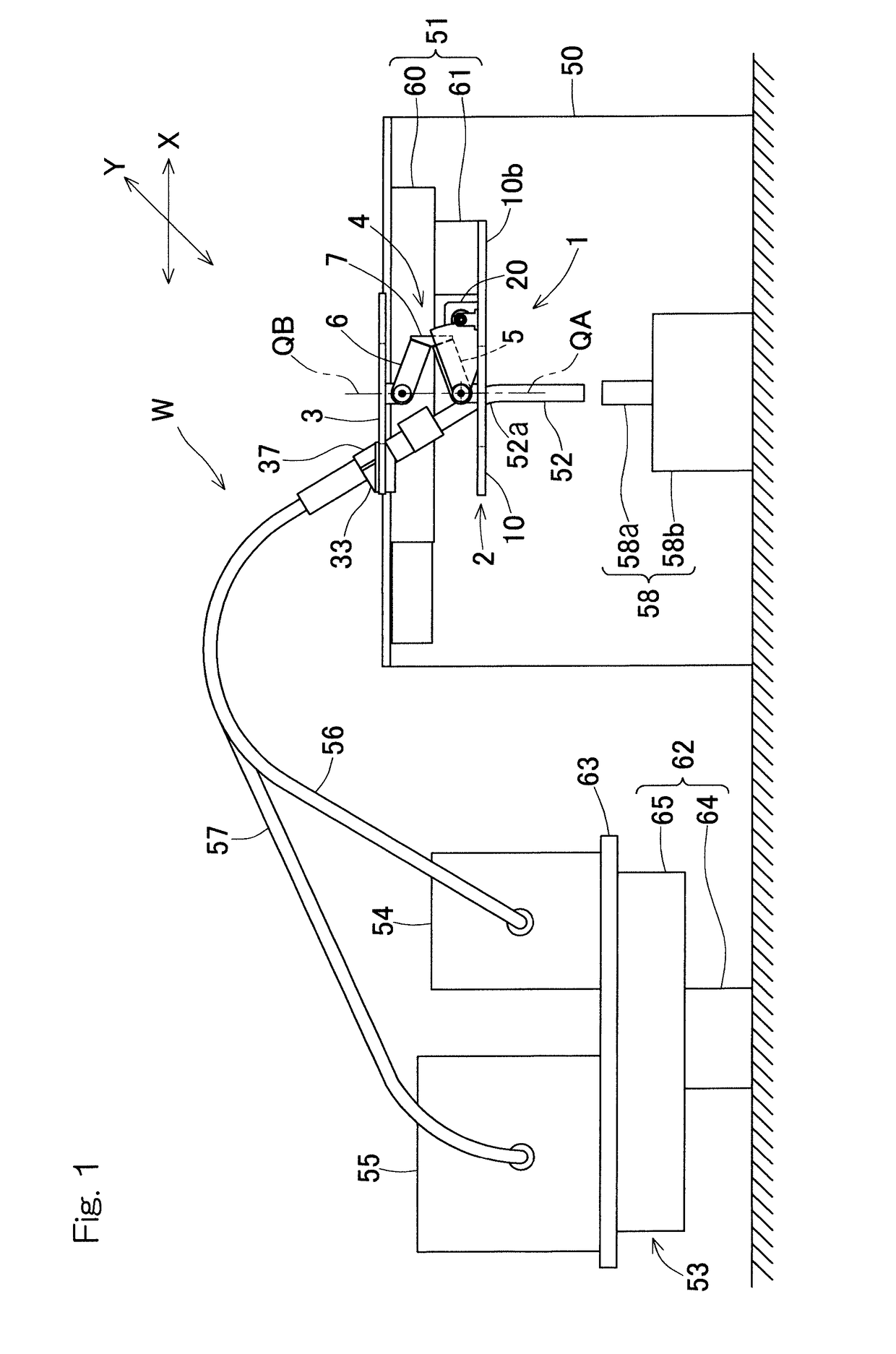

Automatic welding machine

InactiveUS20180200826A1Reduce positioning accuracyConvenient and accurateElectrode holder supportersLinear motionActuator

An automatic welding machine includes a link actuator in which a distal end side link hub is coupled to a proximal end side link hub via three or more link mechanisms and the position of the distal end side link hub relative to the proximal end side link hub can be arbitrarily changed. The automatic welding machine is provided with one or more linear motion actuators configured to cause the proximal end side link hub of the link actuator to advance / retract relative to a mount along respective axes, and a welding torch is mounted on the distal end side link hub. The automatic welding machine further includes a movement mechanism on which peripheral devices connected to the welding torch via cables are mounted so as to be movable in one or more axial directions.

Owner:NTN CORP

Gridline Manufacturing Process for Photovoltaic Cells

ActiveCN104393105BAvoid positioning accuracyMeet the requirements of the contact interfaceFinal product manufacturePhotovoltaic energy generationCelluloseElectrical battery

The invention discloses a gate line manufacturing process for a photovoltaic cell. First slurry and second slurry are respectively put in a container connected with a lower nozzle and an upper nozzle, and the lower nozzle and the upper nozzle have an advancing speed of 125mm / s; the drying temperature of the electrode gate line at the front face of a battery is 140 to 160 DEG C; the first slurry is composed of an organic carrier, silver powder, glass powder, and an ohmic contact additive, and the organic carrier in the first slurry is formed by terpineol, butylcarbitol, ethyl cellulose and allowance according to a 55:30:10:5 weight ratio; the second slurry comprises, at a weight ratio, an organic carrier, silver powder, glass powder and a metal binder; the first slurry layer has a width of 40 to 80mum and a height of 5 to 10mum; and the second slurry layer has a width of 40 to 80mum and a height of 15 to 30mum. The positioning precision problem is solved, the electrode metal gate line itself has good conductive performance, and the height to width ratio of the acquired metal gate line is large.

Owner:SUZHOU ISILVER MATERIALS

Positioning device for copper gasket machining

InactiveCN112894427AAdjustable support radiusSimple structurePositioning apparatusMetal-working holdersElectric machineryEngineering

The invention discloses a positioning device for copper gasket machining. The positioning device for machining comprises a base, and supporting plates are fixedly connected to the base; a platform plate is fixedly connected to each supporting plate, a through hole is formed in the middle of the platform plate, sinking grooves which are evenly distributed in the circumferential direction are formed in the side wall of the through hole, and a through groove is formed in the lower surface of the platform plate; and workpiece fixing mechanisms are slidably connected into the through holes in the platform plates through the sinking grooves, and a control mechanism is arranged between the supporting plates above the base. Compared with the prior art, the device has the beneficial effects that a pressing piece is driven to move downwards under the action of a spring, a copper gasket is fixed to an arc-shaped base plate through the pressing piece, and thus machining is facilitated, chippings are discharged in time, and the problem that the positioning precision is affected is avoided; a threaded shaft is driven by a motor to rotate, so that a sleeve moves up and down, and guide plates slide in the sinking grooves; and the supporting radius of the arc-shaped base plate is adjustable, so that the device can position copper gaskets of various specifications, and the applicability of the device is remarkably improved.

Owner:刘涛

Processing method of pump cover of variable variable oil pump

ActiveCN104999220BAvoid positioning accuracyHigh positioning accuracyLubricating pumpsEngineeringMachining time

The invention provides a variable oil pump cover machining method. The variable oil pump cover machining method comprises the following steps: (A) a pump cover to be machined is positioned on a rotating support plate through a positioning fixture; and firstly, the support plate is in a horizontal state; (B) the frontal surface of the pump cover is roughly machined; and the machining contents comprise rough milling of a shaft side plane, milling of a shaft end surface and a cover plane and drilling of a shaft hole and a hole orifice chambering angle; (C) the frontal surface of the pump cover is finely machined; and the machining contents comprise coating and turning of the shaft side plane and finish boring of the shaft hole; (D) the support plate rotates to be positioned in a direction of 15 degrees; and (E) an inclined oil hole in the inclined surface of the pump cover is drilled. The method is high in machining precision and short in machining time.

Owner:华域皮尔博格泵技术有限公司

Locating method of mobile terminal and related device

ActiveCN101784007BHigh precisionImprove reliabilityLocation information based serviceLocation technologyEmbedded system

The invention discloses a locating method of a mobile terminal and a related device, aiming at solving the problems of lower reliability or accuracy in the existing location technology. The method comprises the steps of: confirming a locating way adopted by relocation when relocation is determined to be carried out by the mobile terminal; and carrying out relocation according to the confirmed locating way.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Gate line manufacturing process for photovoltaic cell

ActiveCN104393105AAvoid positioning accuracyMeet the requirements of the contact interfaceFinal product manufacturePhotovoltaic energy generationOhmic contactTerpineol

The invention discloses a gate line manufacturing process for a photovoltaic cell. First slurry and second slurry are respectively put in a container connected with a lower nozzle and an upper nozzle, and the lower nozzle and the upper nozzle have an advancing speed of 125mm / s; the drying temperature of the electrode gate line at the front face of a battery is 140 to 160 DEG C; the first slurry is composed of an organic carrier, silver powder, glass powder, and an ohmic contact additive, and the organic carrier in the first slurry is formed by terpineol, butylcarbitol, ethyl cellulose and allowance according to a 55:30:10:5 weight ratio; the second slurry comprises, at a weight ratio, an organic carrier, silver powder, glass powder and a metal binder; the first slurry layer has a width of 40 to 80mum and a height of 5 to 10mum; and the second slurry layer has a width of 40 to 80mum and a height of 15 to 30mum. The positioning precision problem is solved, the electrode metal gate line itself has good conductive performance, and the height to width ratio of the acquired metal gate line is large.

Owner:SUZHOU ISILVER MATERIALS

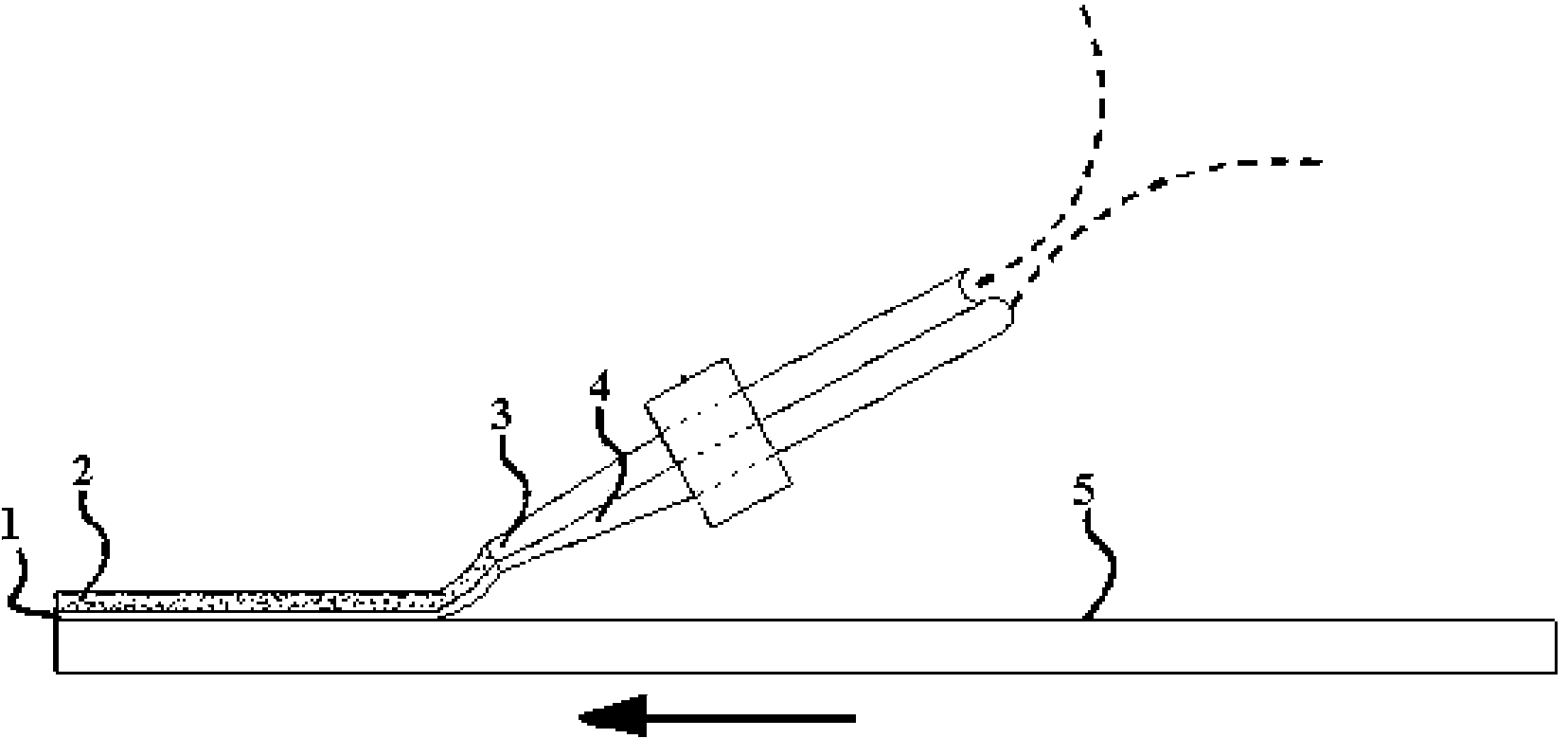

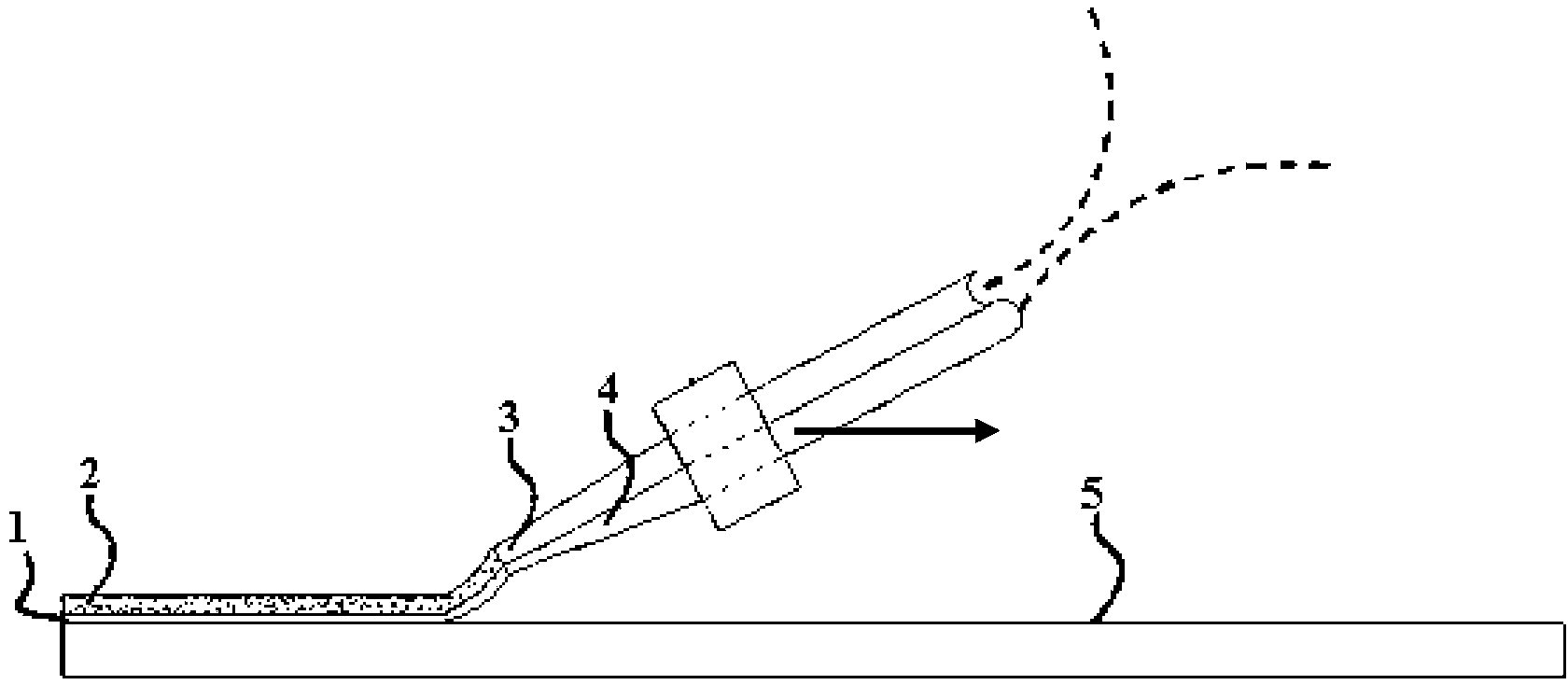

A high-precision explosion source location device for offshore platform tests

The invention provides an offshore platform test high-precision explosion source positioning device. The offshore platform test high-precision explosion source positioning device comprises a fixed sliding rail mounted on the outer wall of a floating impact platform, an upper end sliding block, a lower end sliding block, a moving positioning block, a rotating block, a first-stage connecting cylinder, a first-stage stretching rod, a connecting part, a turnover fold plate, a secondary connecting cylinder, a secondary stretching rod and an end mounting device; the upper end sliding block, the lower end sliding block and the moving positioning block are arranged in the fixed sliding rail from top to bottom, the rotating block is arranged between an upper end fixing block and a lower end fixing block through an end plug pin, the first-stage connecting cylinder is hinged to the rotating block, the first-stage stretching rod is connected with the end of the first-stage connecting cylinder, the connecting part is arranged at the end of the first-stage stretching rod, the turnover fold plate is hinged to the connecting part, the secondary connecting cylinder is connected with the end face of the fold plate, the secondary stretching rod is connected with the end of the secondary connecting cylinder, and the end mounting device is arranged at the end of the secondary connecting cylinder. The offshore platform test high-precision explosion source positioning device is simple in structure, convenient to mount and low in production cost, the device is characterized in that in the test on the floating impact platform, the accurate positioning of an explosion source is achieved, and meanwhile, the explosion source positioning device can be repeatedly dismounted and mounted.

Owner:HARBIN ENG UNIV

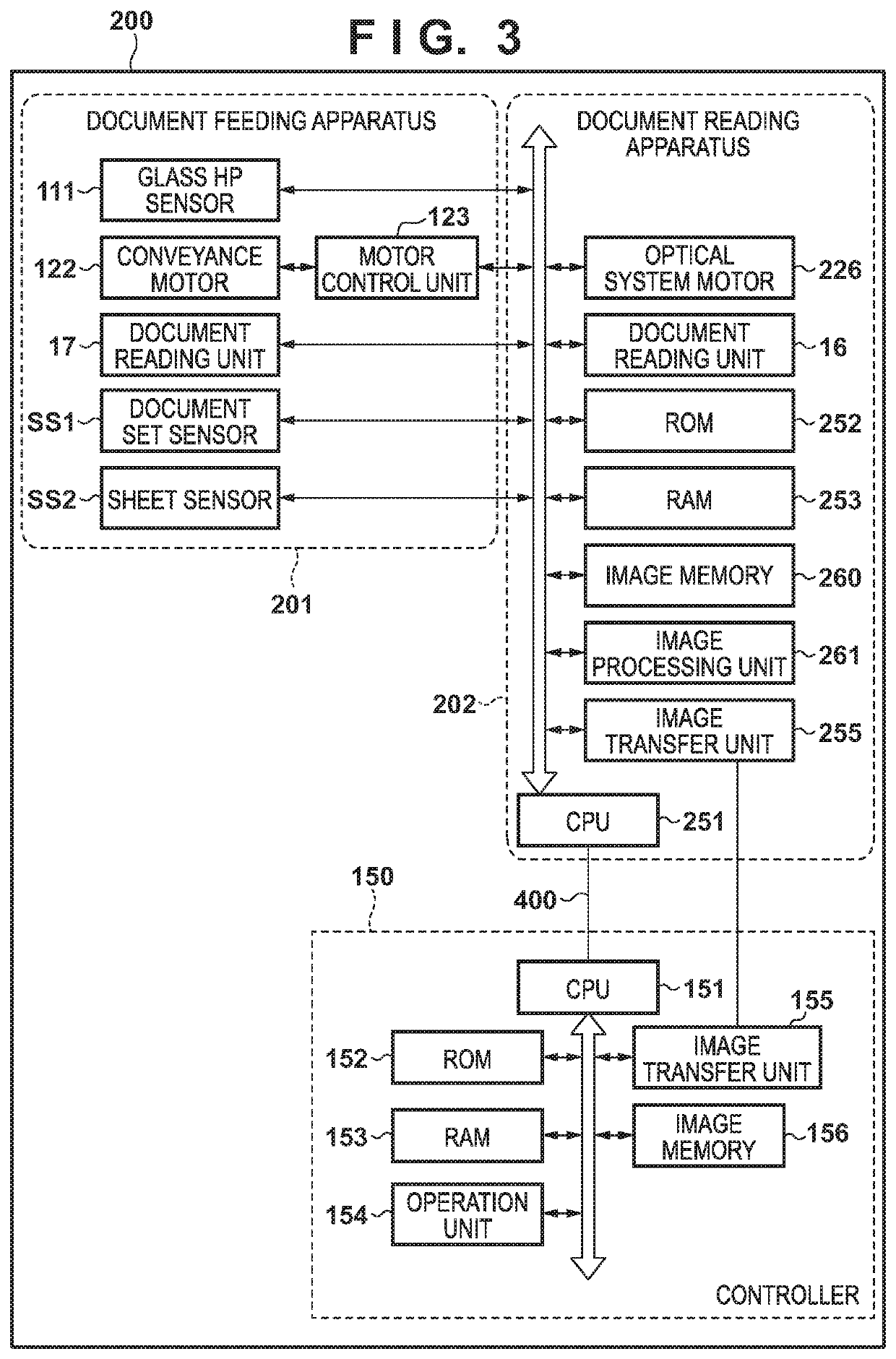

Motor control apparatus, image reading apparatus and image forming apparatus

ActiveUS11349417B2Avoid positioning accuracyReduce biasVector control systemsDynamo-electric converter controlDriving currentControl engineering

A motor control apparatus operable to control a motor includes a phase determiner for determining a rotational phase of a rotor of the motor, and a controller having a first control mode for controlling a driving current flowing through a winding of the motor based on a current of a predetermined magnitude, and a second control mode for controlling a driving current flowing through the winding so that a deviation between a command phase representing a target phase of the rotor and a rotational phase determined by the phase determiner is reduced. The controller executes the first control mode without executing the second control mode in a case of rotating the motor in a first direction, and executes the second control mode in a case of rotating the motor in a second direction which is a reverse direction to the first direction.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com