Process for preparing cathode grid line of solar cell

A technology for solar cells and front electrodes, applied in sustainable manufacturing/processing, circuits, electrical components, etc., to achieve the effects of reducing contact resistance, improving burn-through ability, and enhancing ohmic contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

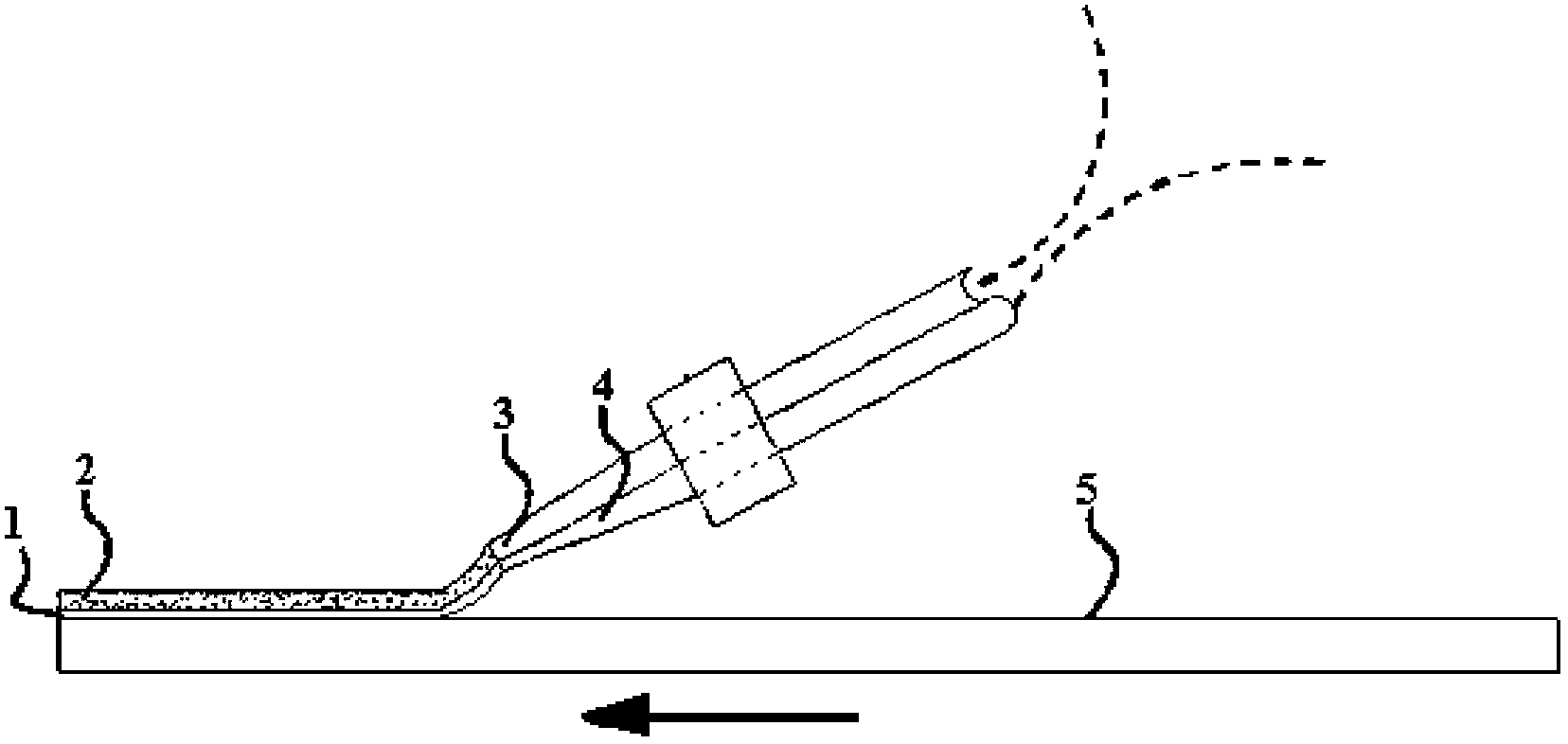

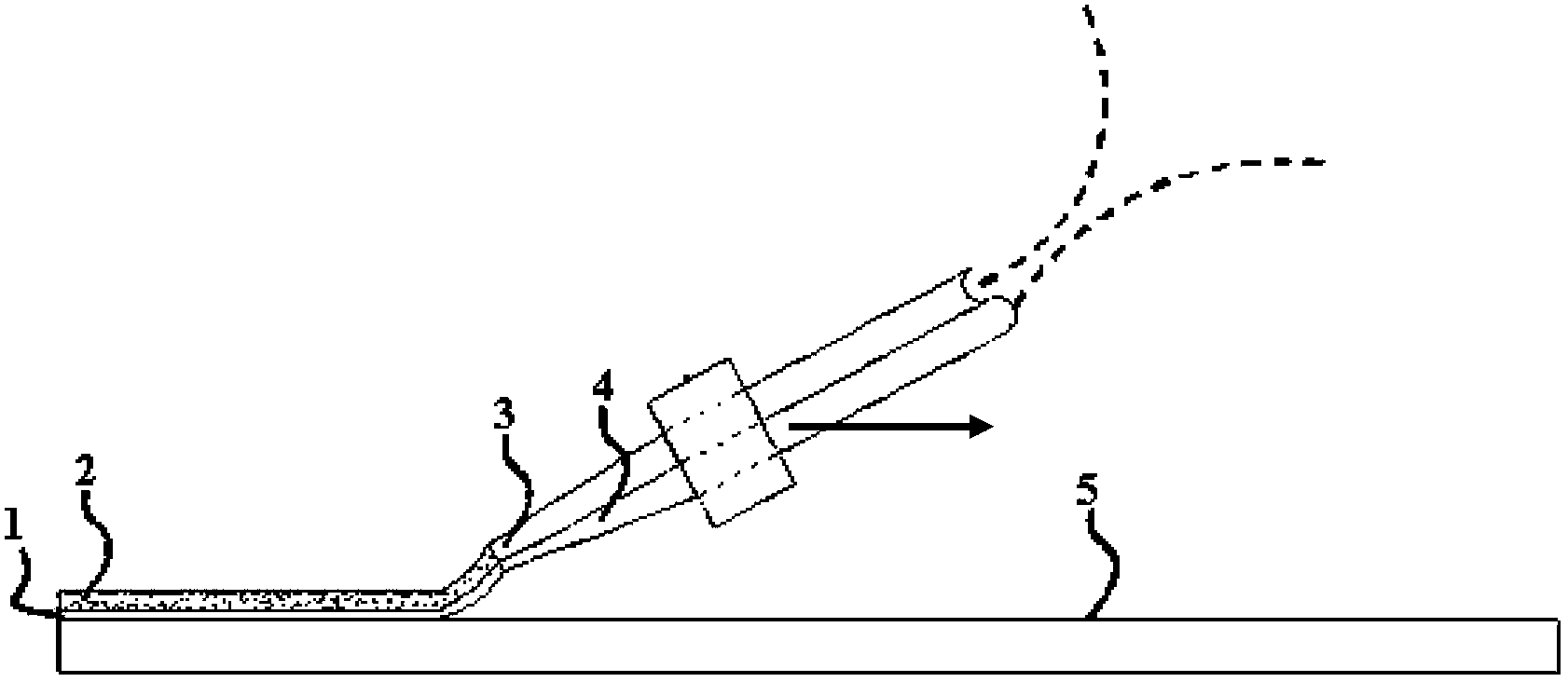

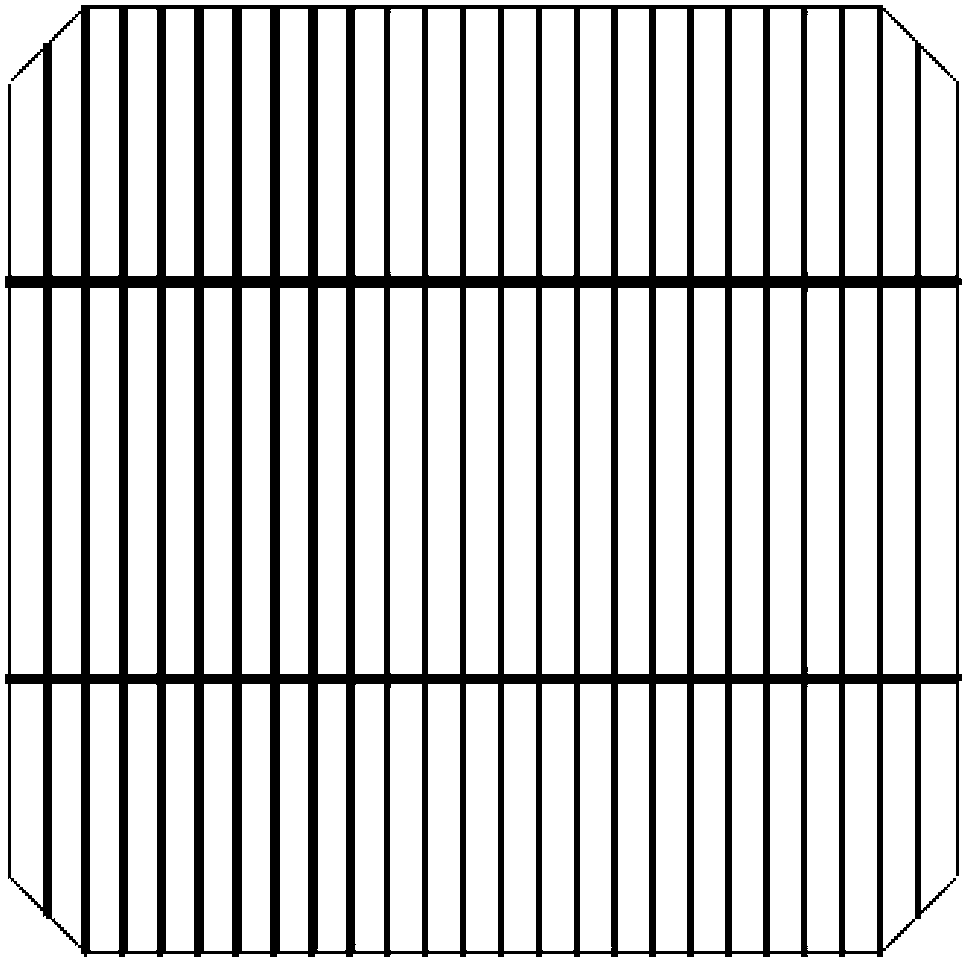

[0036] Embodiment 1-5: A preparation process of solar cell front electrode grid wire, as attached Figure 1-3 As shown, the front electrode grid line of the battery is composed of a first slurry layer 1 and a second slurry layer 2 located on the upper surface of the first slurry layer 1;

[0037] Put the first slurry (A) and the second slurry (B) into containers connected to the lower nozzle 4 and the upper nozzle 3 respectively, the lower nozzle 4 and the upper nozzle are arranged in parallel closely and the upper nozzle 3 Located on the upper side of the lower nozzle 4; the spraying pressure of the lower nozzle 4 is 0.5MPa, the spraying pressure of the upper nozzle 3 is 0.65MPa, and the travel speed of the lower nozzle 4 and the upper nozzle 3 is 125mm / s; the front electrode grid line of the battery 5 is baked Drying temperature 140~160℃, drying time 14~16 minutes;

[0038] The first slurry (A) is composed of the following components in parts by weight:

[0039] Organic ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com