Method for manufacturing solar cell grid line

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, conductive materials dispersed in non-conductive inorganic materials, etc., to reduce contact resistance, improve burn-through ability, and enhance ohmic contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

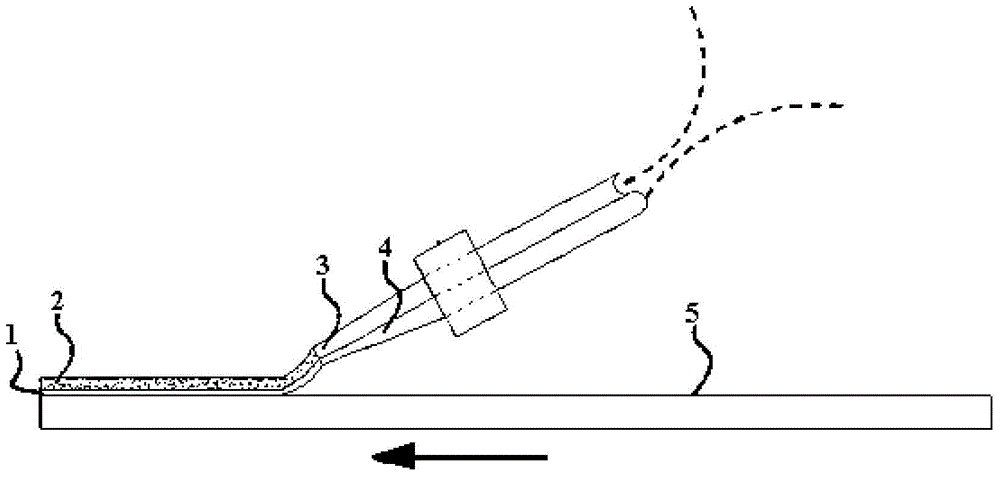

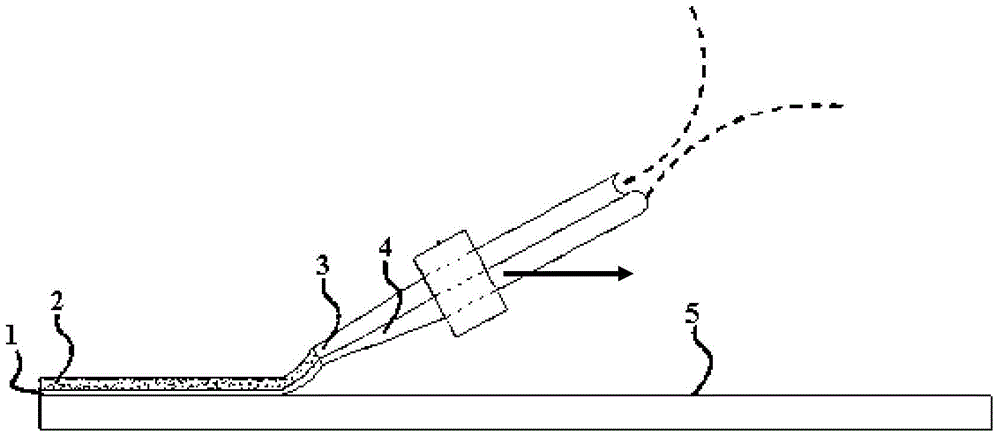

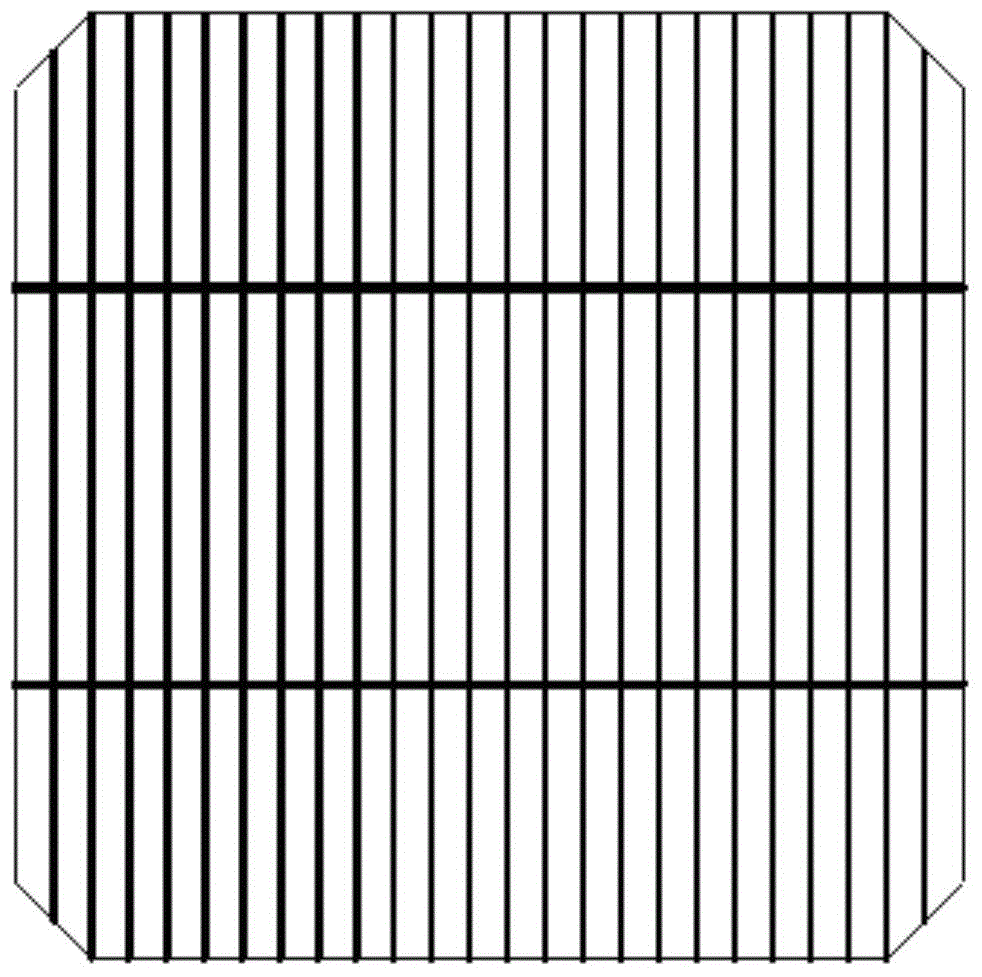

[0033] Embodiment 1-5: A method for manufacturing solar cell grid lines, the battery front electrode grid line is composed of a first paste layer 1 and a second paste layer 2 located on the upper surface of the first paste layer 1 ;

[0034] The first slurry and the second slurry are respectively loaded into containers connected to the lower nozzle 4 and the upper nozzle 3, the lower nozzle 4 and the upper nozzle 3 are arranged in parallel closely and the upper nozzle 3 is located on the upper side of the lower nozzle 4 , the travel speed of the lower nozzle 4 and the upper nozzle 3 is 125mm / s; the drying temperature of the front electrode grid of the battery is 140~160°C;

[0035] The first slurry is made up of the following components in parts by weight:

[0036] Organic vehicle 23 parts,

[0037] 70 parts of silver powder,

[0038] 5 parts glass powder,

[0039] Ohmic contact additive 2 parts,

[0040] The organic vehicle in the first slurry is formed by heating terpin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com