GaN-based HEMT low-temperature gold-free ohmic contact electrode and preparation method thereof

A technology of ohmic contact electrodes and ohmic contact, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as limiting use, affecting device dynamic performance, and increasing material square resistance, so as to promote ohmic contact and improve Effects of free carrier concentration and lower annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the GaN-based HEMT low-temperature gold-free ohmic contact of this embodiment includes the following steps:

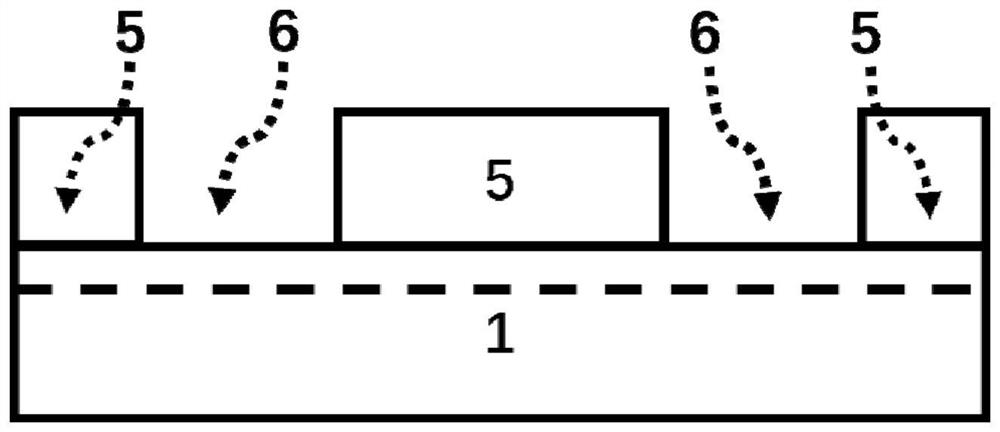

[0044] (1) Using photolithography technology to define source and drain etching pattern areas on the GaN-based epitaxial layer;

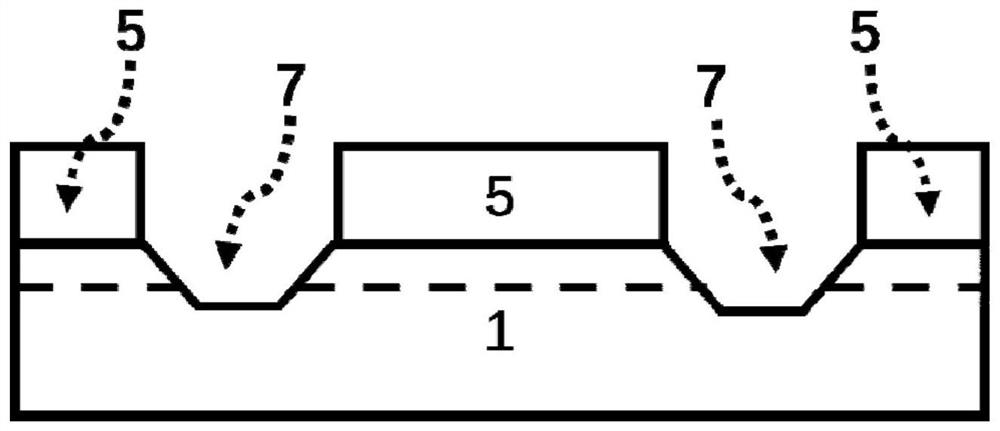

[0045] (2) Using ICP etching technology, the AlGaN barrier layer is completely etched away, and etched to the GaN channel layer (the dotted line in the figure refers to the 2DEG channel, and the GaN channel layer below it) down to 10nm , the etching inclination angle is 50°;

[0046] (3) On the basis of retaining the photoresist, use an acid-base solution to clean the source-drain etching pattern obtained in step (2);

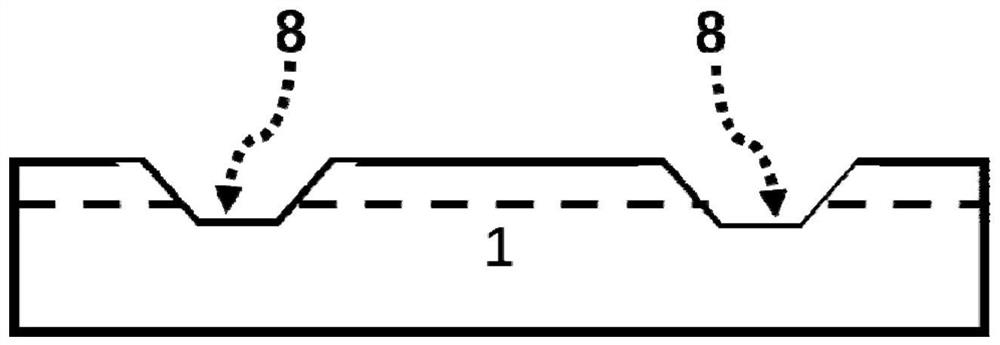

[0047] (4) Remove the photoresist in step (3), and after cleaning, put the obtained GaN-based epitaxial layer into a rapid thermal annealing system for surface oxidation treatment to remove the exposed AlGaN / GaN heterojunction sidewall after etching Treat with the GaN channel layer, the anne...

Embodiment 2

[0053] The preparation method of the GaN-based HEMT low-temperature gold-free ohmic contact of this embodiment includes the following steps:

[0054] (1) Using photolithography technology to define source and drain etching pattern areas on the GaN-based epitaxial layer;

[0055] (2) Using ICP etching technology, the AlGaN barrier layer is completely removed, and etched to 20nm below the GaN channel layer, with an etching inclination angle of 40°;

[0056] (3) cleaning the source-drain etching pattern obtained in step (2) by using an acid-base solution;

[0057] (4) Remove the photoresist in step (3), and after cleaning, put the obtained GaN-based epitaxial layer into a rapid thermal annealing system for surface oxidation treatment to remove the exposed AlGaN / GaN heterojunction sidewall after etching Treat with the GaN channel layer, the annealing temperature is 350°C, the annealing time is 20min, and the atmosphere is high-purity oxygen;

[0058] (5) Using photolithography t...

Embodiment 3

[0063] The preparation method of the GaN-based HEMT low-temperature gold-free ohmic contact of this embodiment includes the following steps:

[0064] (1) Using photolithography technology to define source and drain etching pattern areas on the GaN-based epitaxial layer;

[0065] (2) Using ICP etching technology, the AlGaN barrier layer is completely removed, and etched to 50nm below the GaN channel layer, and the etching inclination angle is 20°;

[0066] (3) cleaning the source-drain etching pattern obtained in step (2) by using an acid-base solution;

[0067] (4) Remove the photoresist in step (3), and after cleaning, carry out oxygen plasma treatment on the GaN-based epitaxial layer to treat the exposed AlGaN / GaN heterojunction sidewall and GaN channel layer after etching. Treatment, the oxygen flow rate is 60sccm, the power is 250W, and the time is 200s;

[0068] (5) Using photolithography technology, define a source-drain ohmic contact pattern area for the GaN-based epi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com