Pre-machining process of spinning hub

A technology of pre-processing and spinning wheels, which is applied in the field of spinning wheel hub pre-processing technology, can solve the problems of inaccurate automatic positioning accuracy, unstable mechanical performance, and easy interruption of the production process, so as to achieve favorable mechanical properties, improve efficiency and Quality, homogeneous effect after preprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

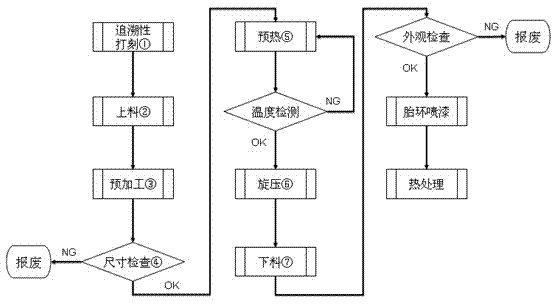

[0032] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0033] see figure 1 As shown, it is the flow chart of the spinning hub preprocessing process of the present invention, and the specific process is:

[0034] Step a, the operator places the rough material of the rim on the engraving platform, and uses the engraving pattern to perform retrospective engraving at a fixed position. The engraving information is the processing information of the rim, including: month, day, and shift;

[0035] Step b: Load the engraved rough rim material to the conveyor belt. When the rough rim material passes through the conveyor belt and moves to the top of the conveyor belt, position the rough rim material. After positioning, the conveyor belt transmits the signal to the manipulator , the manipulator runs the program after receiving the signal;

[0036] The rough material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com