Gridline Manufacturing Process for Photovoltaic Cells

A manufacturing process and grid line technology, which is applied in the field of solar cell preparation, can solve problems such as silicon chip fragmentation, and achieve the effects of enhancing ohmic contact, improving burn-through ability, and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

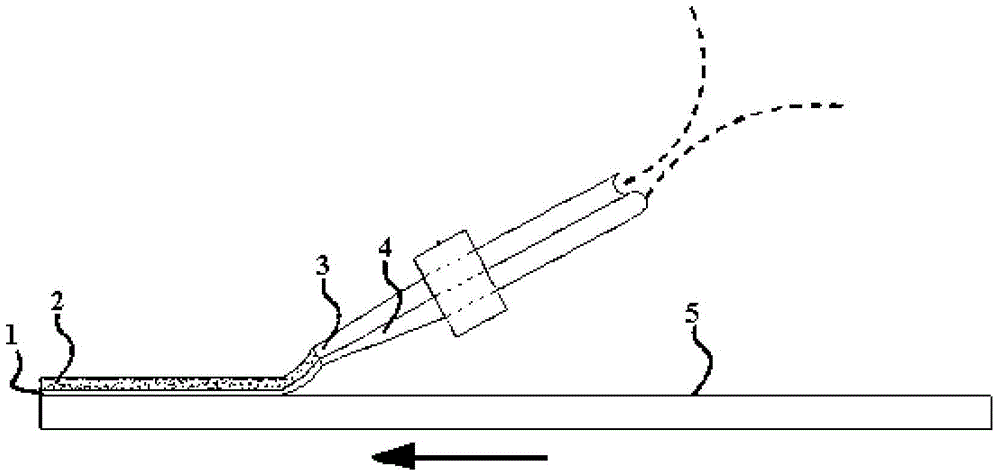

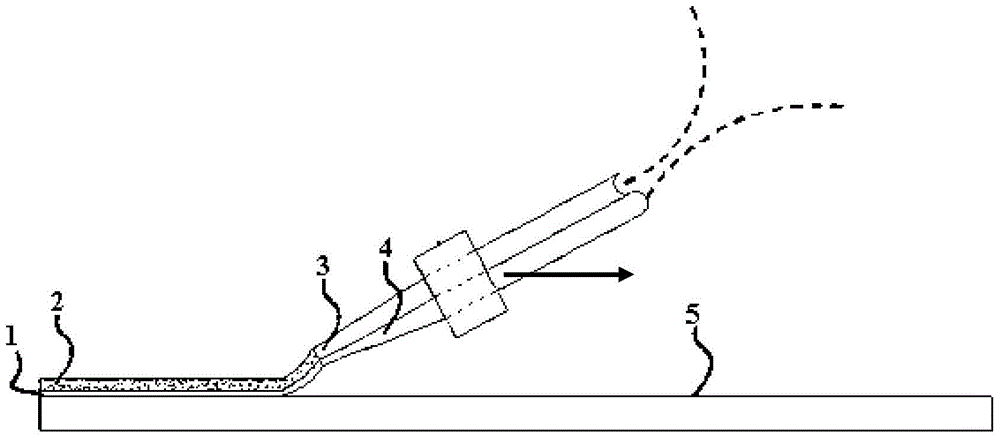

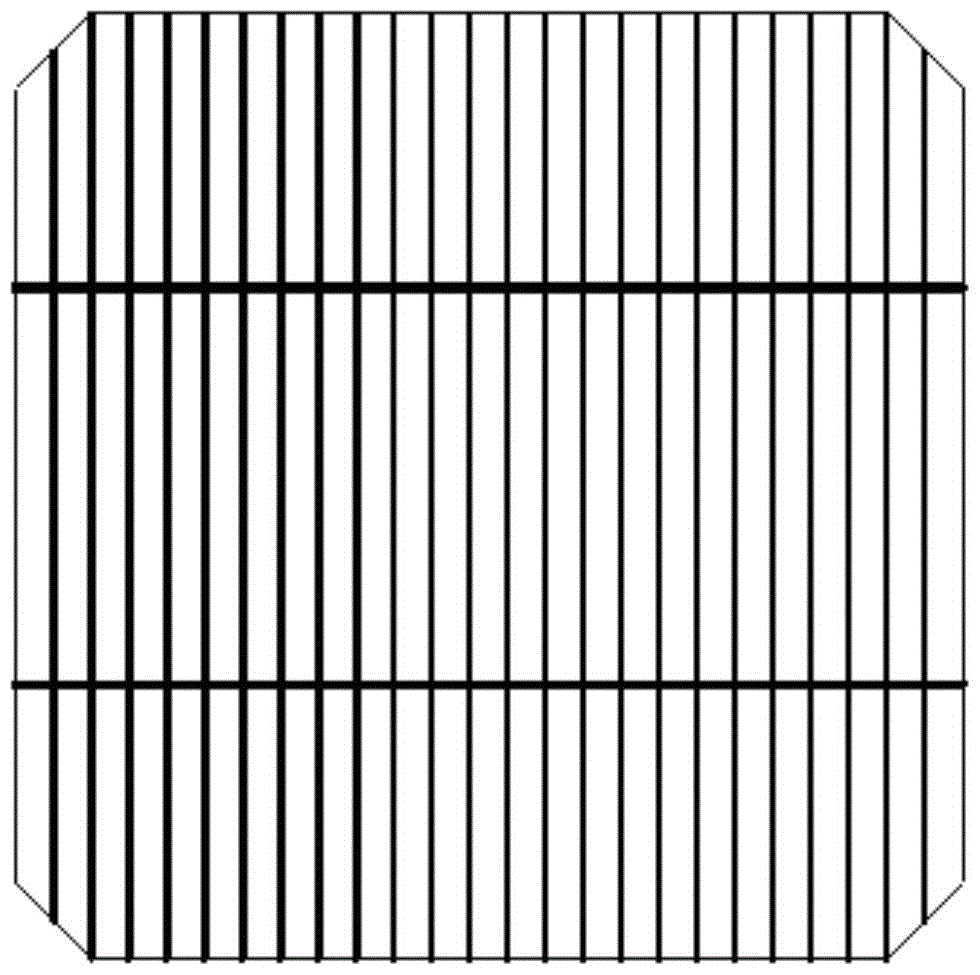

[0036] Embodiment 1-5: A grid wire manufacturing process for photovoltaic cells, as attached Figure 1-3 As shown, the front electrode grid line of the battery is composed of a first slurry layer 1 and a second slurry layer 2 located on the upper surface of the first slurry layer 1;

[0037] Put the first slurry (A) and the second slurry (B) into containers connected to the lower nozzle 4 and the upper nozzle 3 respectively, the lower nozzle 4 and the upper nozzle are arranged in parallel closely and the upper nozzle 3 Located on the upper side of the lower nozzle 4; the spraying pressure of the lower nozzle 4 is 0.5MPa, the spraying pressure of the upper nozzle 3 is 0.65MPa, and the travel speed of the lower nozzle 4 and the upper nozzle 3 is 125mm / s; the front electrode grid line of the battery 5 is baked Drying temperature 140~160℃, drying time 14~16 minutes;

[0038] The first slurry (A) is composed of the following components in parts by weight:

[0039] Organic vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com