Chain piece machining device

A technology for processing devices and chains, which is applied in positioning devices, clamping devices, metal processing, etc., can solve the problems that the clamping positions of the chains cannot be guaranteed, the relative position is not accurate enough, and the processing and production efficiency is low, so as to achieve automation Assembly line operation, precise processing, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now in conjunction with accompanying drawing and specific embodiment, the present invention is further described, wherein CNC controller, rotary table, boring mechanism, drilling mechanism, feeding conveying mechanism, discharging conveying mechanism and manipulator are all existing components, patented in China Documents: CN201821841167.0, CN201621341339.9, CN201920116938.8, etc. have been disclosed.

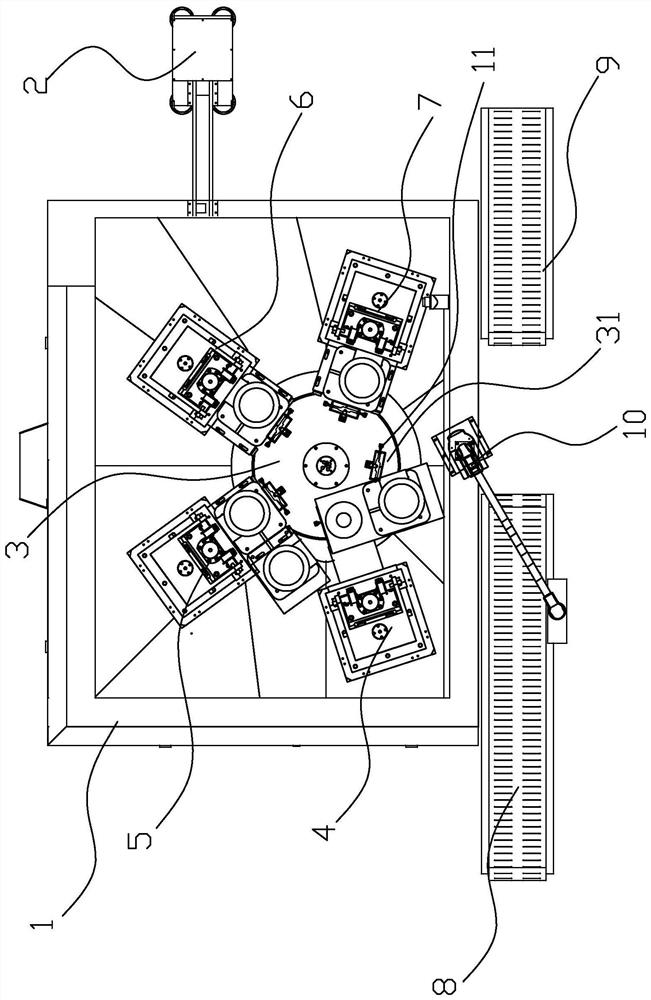

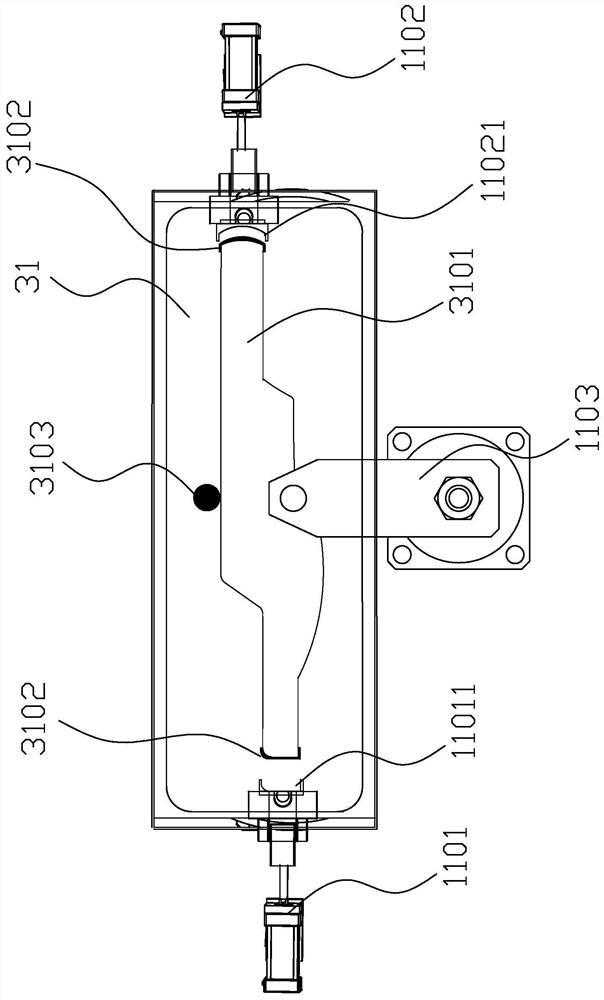

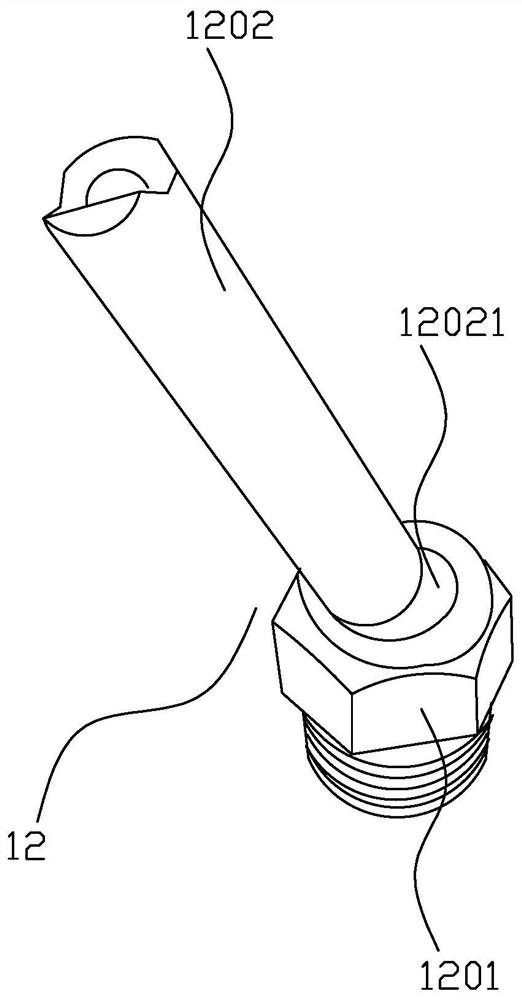

[0016] refer to figure 1 , figure 2 with image 3, the preferred link processing device of the present invention includes a frame 1, a CNC controller 2 arranged on the frame 1, a rotary table 3, a first boring mechanism 4, a second boring mechanism 5, a first drill Hole mechanism 6, second drilling mechanism 7, feeding conveying mechanism 8, discharging conveying mechanism 9, manipulator 10, five clamping mechanisms 11, first blowing mechanism, second blowing mechanism, third blowing mechanism and the fourth blowing mechanism, five fixing seats 301 for placing chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com