Low-temperature solution method synthesis process of novel long-afterglow perovskite crystal

A low-temperature solution method and synthesis process technology, applied in the field of materials science, can solve the problems such as hindering the application of long afterglow materials and the loss of morphology of precursors such as nanomaterials, and achieve the effect of clear crystal plane and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Put cesium chloride, silver chloride, indium chloride, manganese chloride, edetate disodium and concentrated hydrochloric acid into the polytetrafluoroethylene liner according to the chemical dosage ratio, and then put the polytetrafluoroethylene The liner is sealed in a stainless steel autoclave;

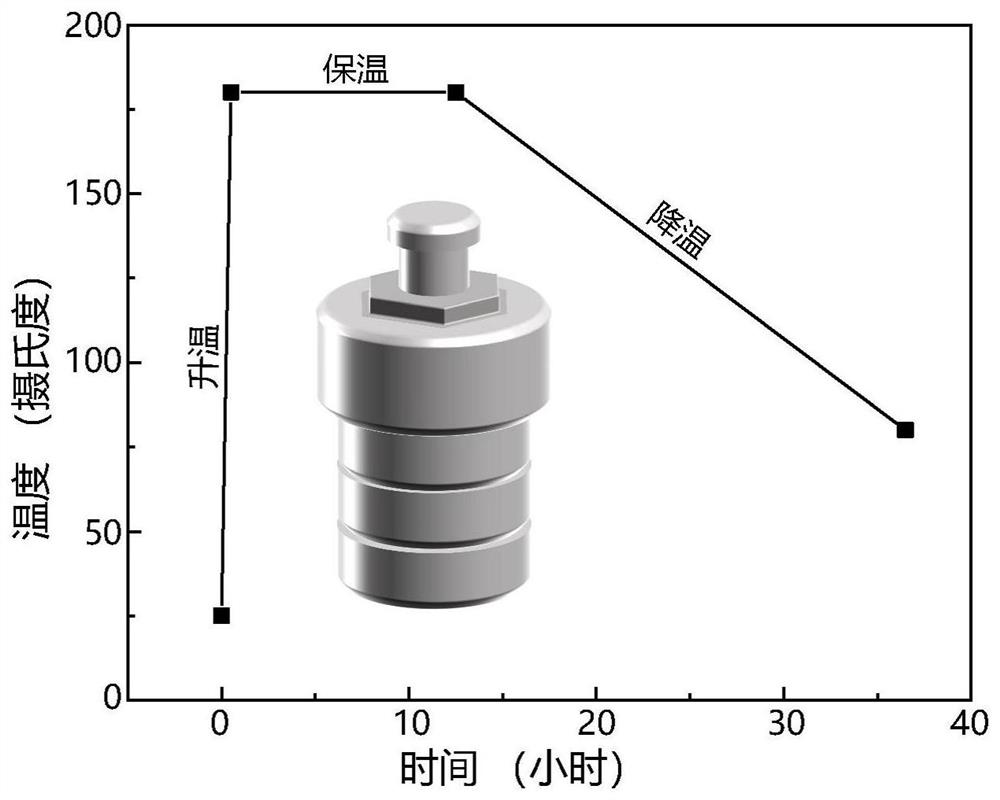

[0044] 2) Put the stainless steel autoclave into the muffle furnace, heat it to 180°C within 1h, and keep it for 12h, slowly cool the muffle furnace to 80°C within 24 hours, and finally cool it naturally to room temperature;

[0045]3) Open the reactor, discard the upper liquid, place the bottom crystal on absorbent paper, and rinse the single crystal with isopropanol for 3 to 5 times, then use filter paper to absorb the isopropanol on the surface to obtain perovskite long afterglow crystals .

[0046] The step 1) concentrated hydrochloric acid is hydrochloric acid with a concentration of 36-38%.

[0047] According to the stoichiometric dosage ratio Cs in the step 1) 2...

Embodiment 2

[0053] 1) Put cesium chloride, silver chloride, indium chloride, manganese chloride, edetate disodium and concentrated hydrochloric acid into the polytetrafluoroethylene liner according to the chemical dosage ratio, and then put the polytetrafluoroethylene The liner is sealed in a stainless steel autoclave;

[0054] 2) Put the stainless steel autoclave into the muffle furnace, heat it to 180°C within 1h, and keep it for 12h, slowly cool the muffle furnace to 80°C within 106h, and finally cool it naturally to room temperature;

[0055] 3) Open the reactor, discard the upper liquid, place the bottom crystal on absorbent paper, and rinse the single crystal with isopropanol for 3 to 5 times, then use filter paper to absorb the isopropanol on the surface to obtain perovskite long afterglow crystals .

[0056] The step 1) concentrated hydrochloric acid is hydrochloric acid with a concentration of 36-38%.

[0057] According to the stoichiometric dosage ratio Cs in the step 1) 2 Na...

Embodiment 3

[0063] 1) Put cesium chloride, silver chloride, indium chloride, manganese chloride, disodium edetate and concentrated hydrochloric acid into the polytetrafluoroethylene liner according to the stoichiometric ratio, and then put the polytetrafluoroethylene The liner is sealed in a stainless steel autoclave;

[0064] 2) Put the stainless steel autoclave into the muffle furnace, heat it to 180°C within 1h, and keep it for 12h, slowly cool the muffle furnace to 80°C within 48h, and finally cool it naturally to room temperature; (such as figure 1 shown);

[0065] 3) Open the reactor, discard the upper liquid, place the bottom crystal on absorbent paper, and rinse the single crystal with isopropanol for 3 to 5 times, then use filter paper to absorb the isopropanol on the surface to obtain perovskite long afterglow crystals .

[0066] The step 1) concentrated hydrochloric acid is hydrochloric acid with a concentration of 36-38%.

[0067] According to the stoichiometric dosage rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com