Yarn waxing machine facilitating rapid waxing and used for spinning

A yarn and wax machine technology, used in textiles and papermaking, can solve problems such as affecting the efficiency of yarn waxing, unable to ensure the continuity of equipment work, avoiding free rotation, ensuring stability, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

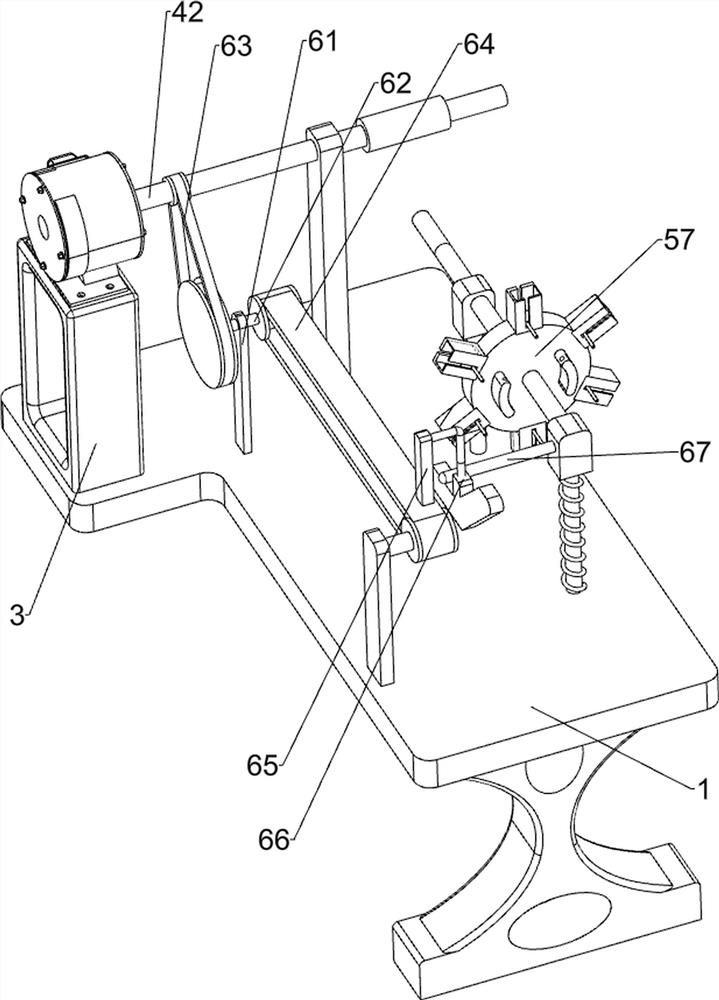

[0031] A kind of yarn waxing machine that is convenient for fast waxing for weaving, such as Figure 1 to Figure 5 As shown, it includes a base 1, a material guide plate 2, a support 3, a driving mechanism 4, a wax release mechanism 5, a transmission mechanism 6 and a telescopic mechanism 7. The top of the base 1 is connected with a material guide plate 2 in the middle, and the top of the base 1 The rear side is connected with a support 3, a drive mechanism 4 is connected between the support 3 and the base 1, a wax discharge mechanism 5 is installed in the middle of the top of the base 1, and a transmission mechanism 6 is connected between the drive mechanism 4 and the wax discharge mechanism 5. The wax release mechanism 5 is connected with a telescopic mechanism 7 .

[0032] The driving mechanism 4 includes a motor 41, a first shaft rod 42, a first fixed plate 43, a second fixed plate 44 and a first fixed rod 45. The top of the support 3 is connected to the motor 41, and the ...

Embodiment 2

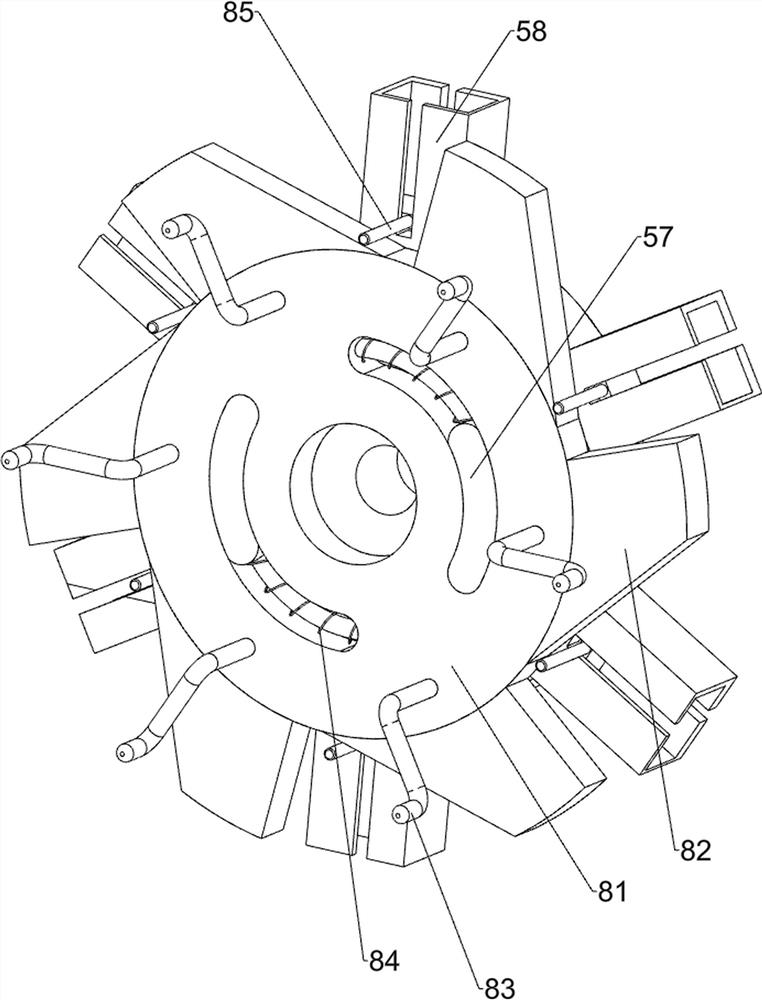

[0038] On the basis of Example 1, such as Figure 6 and Figure 7 As shown, it also includes a wax removal mechanism 8, and the wax removal mechanism 8 includes a second disc 81, a second inclined block 82, a Z-shaped rotating rod 83, an arc spring 84 and a contact rod 85, and the first disc 57 is rotatably connected with a second disc 81, and the second disc 81 is connected with second oblique blocks 82 equal in number to the number of wax-discharging tanks 58 at even intervals around the second disc 81, and the sides of the second disc 81 are evenly spaced. The ground is connected with a Z-shaped rotating rod 83, an arc spring 84 is connected between the first disk 57 and the second disk 81, and a contact rod 85 is connected on each sliding plate 59, and the contact rod 85 and the second oblique Block 82 is a contact fit.

[0039] When all the wax pieces in the wax putting tank 58 are used up and need to be replaced, the Z-shaped rotating rod 83 is manually rotated, and th...

Embodiment 3

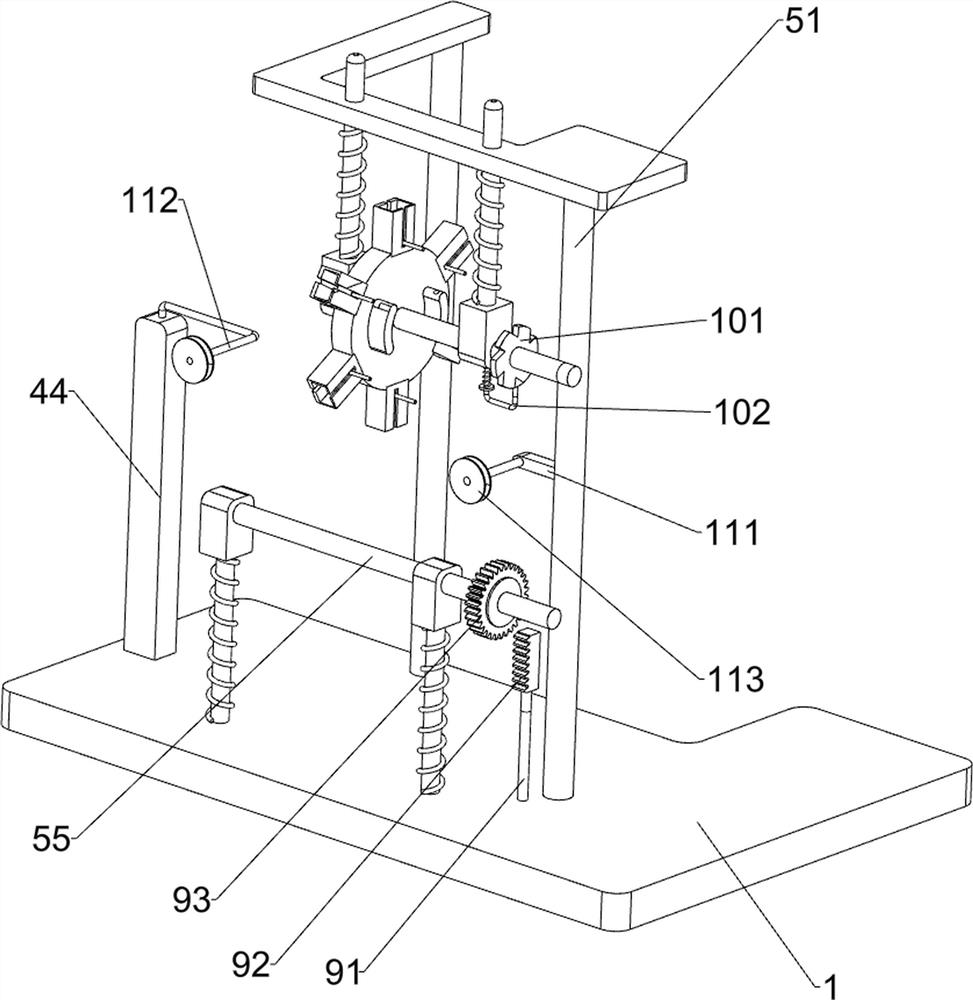

[0043] On the basis of Example 2, such as Figure 7 As shown, it also includes a limit mechanism 10. The limit mechanism 10 includes a sheave 101 and an elastic matching rod 102. The right part of the second shaft rod 55 on the upper and lower sides is connected with a sheave 101, and the first fixed block 54 is connected with a sheave 101. There is an elastic fitting rod 102 that cooperates with the sheave 101 .

[0044] When the second shaft 55 rotates, the sheave 101 rotates accordingly, and the sheave 101 rotates to forcibly push the elastic fitting rod 102 away. When the next slot of the sheave 101 is aligned with the elastic fitting rod 102, the elastic fitting rod 102 is snapped into the draw-in groove of the sheave 101, so that the sheave 101 can be fixed, avoiding the free rotation of the second axle rod 55, and ensuring the stability of the equipment when waxing.

[0045] Also includes a positioning assembly 11, the positioning assembly 11 includes a first connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com