Stone static crushing construction method

A static crushing and construction method technology, applied in blasting and other directions, can solve problems such as huge vibration and noise, and achieve the effects of fast crushing speed, high crushing efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

[0029] A construction method for static crushing of stonework provided by the invention comprises the following steps:

[0030] (1) Preparation of static crushing agent: calcium oxide is used as the main body, and after high-temperature calcination, it is mixed with external materials with a mass of 5-10% of the mass of calcium oxide and ground together to obtain a non-crushing powdery material with high expansion performance. That is, static crushing agent, the calcining temperature of calcium oxide is above 1400°C;

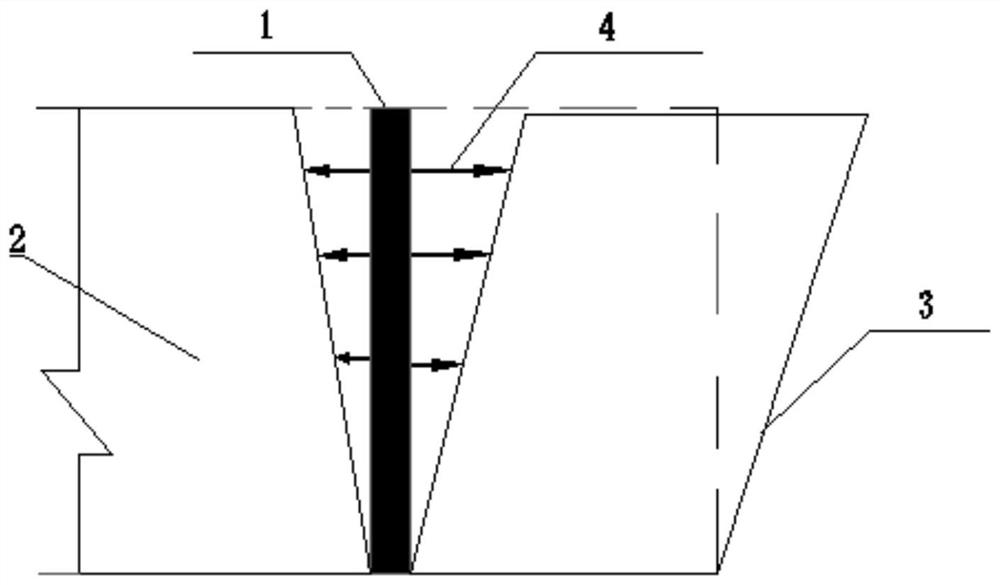

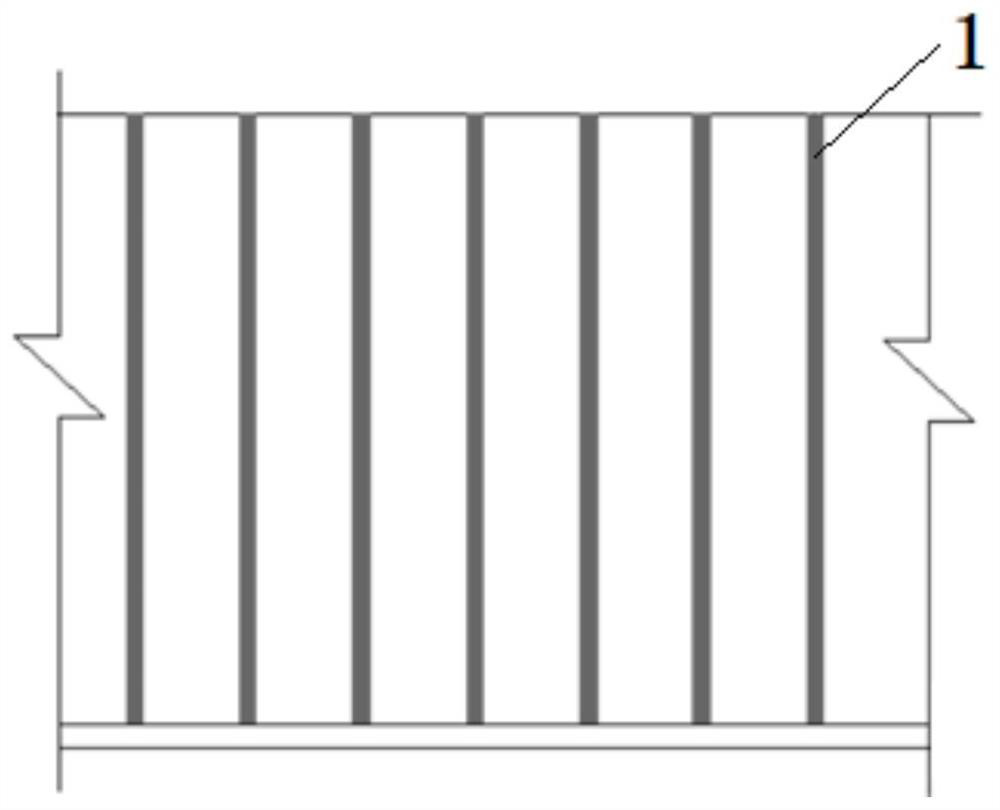

[0031] (2) Drilling: According to the pre-designed hole spacing and row spacing, the hole-shaped holes are arranged in a trapezoidal shape, and the rock drilling machine is used to drill holes. The drilling should reach the hole depth required by the design. For rocks, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com