Welding seam deflection measuring method for tailor-welded blank spinning forming curved surface component

A technology of spinning forming and measuring method, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of lack of research and patents, and achieve the effects of precise measurement, large curvature changes, and improved forming ability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

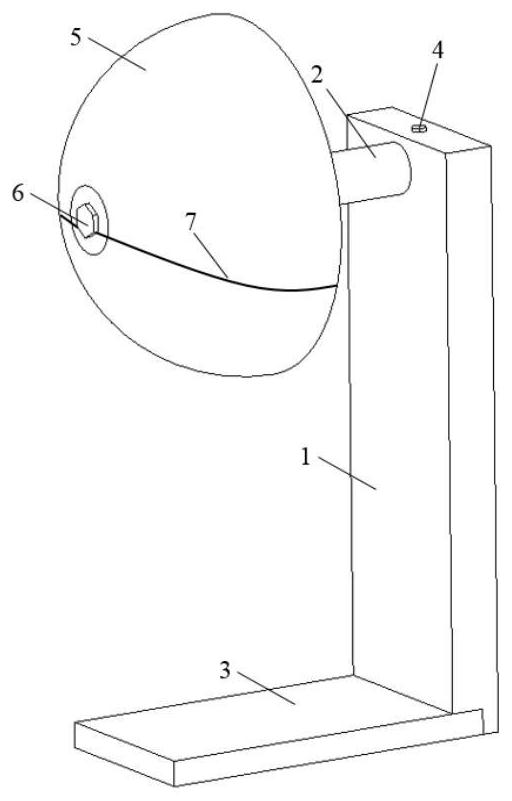

[0044] This embodiment is a method for measuring the deflection angle of a weld seam through the outer surface of a thin-walled curved member formed by spinning a tailored welded blank.

[0045] The workpiece to be tested is formed by spinning of an aluminum alloy tailor welded blank, and its shape is a hemispherical shell. The bottom of the hemisphere of the tested workpiece has a mounting hole; the diameter of the mouth of the hemisphere of the tested workpiece is the largest, which is 300mm. There is an original welding seam extending from the bottom to the mouth on the curved surface of the measured workpiece, and one end of the original welding seam forms an intersection K with the edge of the mouth.

[0046] The concrete process of this embodiment is:

[0047] Step 1, the assembly of the measuring stand:

[0048] Fix the measuring stand on the work surface.

[0049] Step 2, install the workpiece under test:

[0050] The tailor-welded blank is used as the workpiece to...

Embodiment 2

[0068] This embodiment is a method for measuring the deflection angle of a weld seam through the inner surface of a thin-walled curved member formed by spinning a tailored welded blank.

[0069] The workpiece to be tested is formed by spinning of an aluminum alloy tailor welded blank, and its shape is a hemispherical shell. The bottom of the hemisphere of the tested workpiece has a mounting hole; the diameter of the mouth of the hemisphere of the tested workpiece is the largest, which is 300mm. There is an original welding seam extending from the bottom to the mouth on the curved surface of the measured workpiece, and one end of the original welding seam forms an intersection K with the edge of the mouth.

[0070] The concrete process of this embodiment is:

[0071] Step 1, measuring frame assembly:

[0072] Fix the measuring frame on the workbench.

[0073] Step 2, install the workpiece under test:

[0074] The tailor-welded blank is used as the workpiece to be tested. W...

Embodiment 3

[0092]This embodiment is a measuring frame for realizing the measurement of the deflection angle of the weld seam on the inner surface or the outer surface of the thin-walled curved surface member formed by spinning of the tailored welded blank.

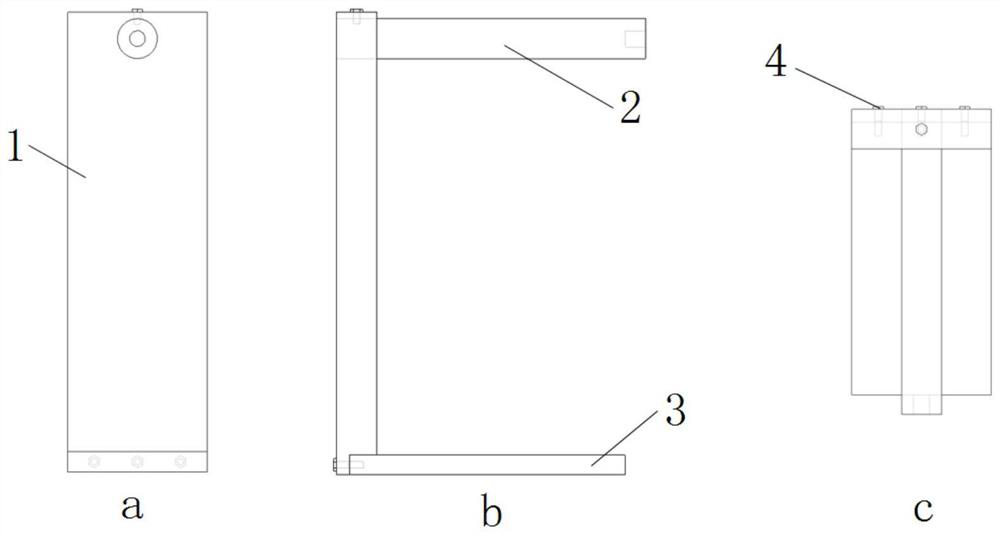

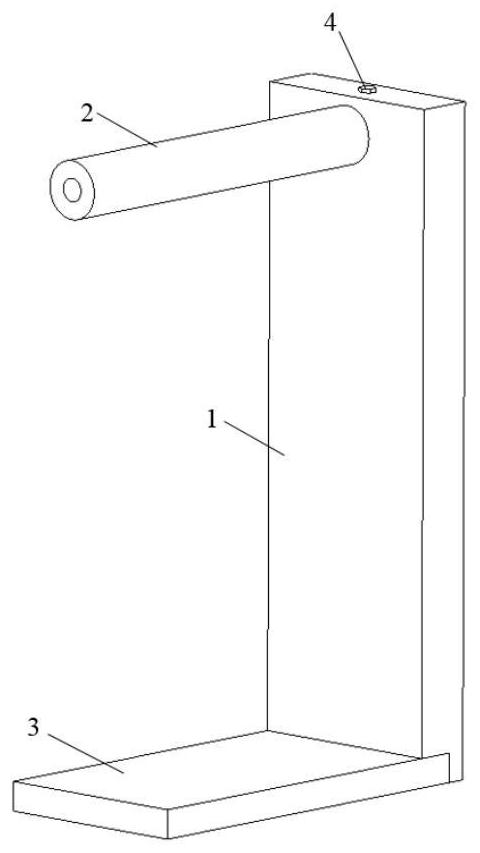

[0093] The shape of the measuring frame is "concave", including a vertical support plate 1, a horizontal fixing rod 2, a horizontal bottom plate 3, a locking screw 4 and a locking screw 5 of the workpiece under test, and a laser level 8 used in conjunction with it .

[0094] The vertical support plate 1 is the supporting connector of the whole device; a horizontal fixing rod 2 is fixed on the upper end of one side surface of the support plate, and a horizontal bottom plate 3 is fixed on the lower end surface. Both the horizontal fixing rod and the horizontal bottom plate are cantilever beam structures.

[0095] The lower end surface of the support plate fixedly connected with the horizontal bottom plate is stepped. And the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com