Preparation method of high-temperature alloy metallographic specimen

A technology for metallographic samples and diamonds, which is applied in the field of preparing high-temperature alloy metallographic samples using automatic grinding and polishing machines, to achieve the effects of fewer types of consumables, easy automatic sample preparation, and reduced surface residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The present embodiment prepares a GH141 high-temperature alloy gold phase sample, and its preparation method includes the steps of:

[0064] Step 1: Cut the test sample according to the detection requirements and the automatic grinding clip holder size.

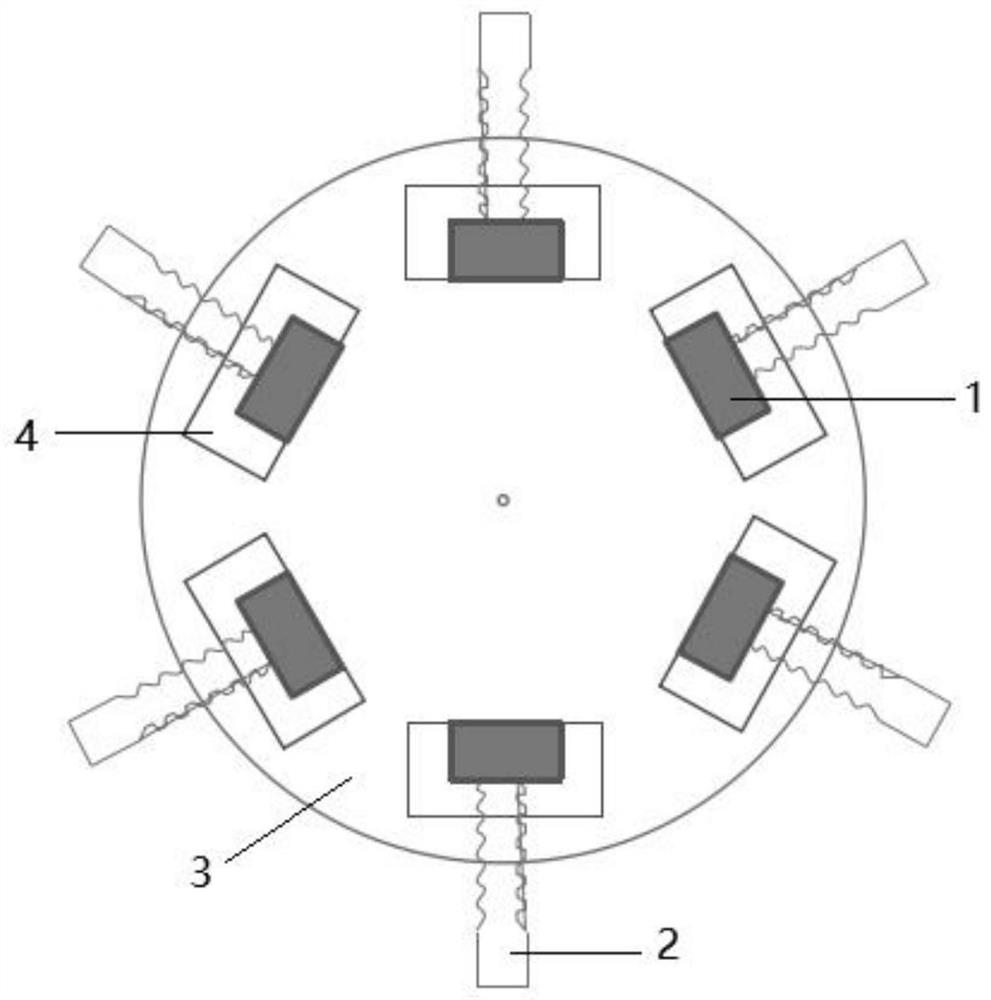

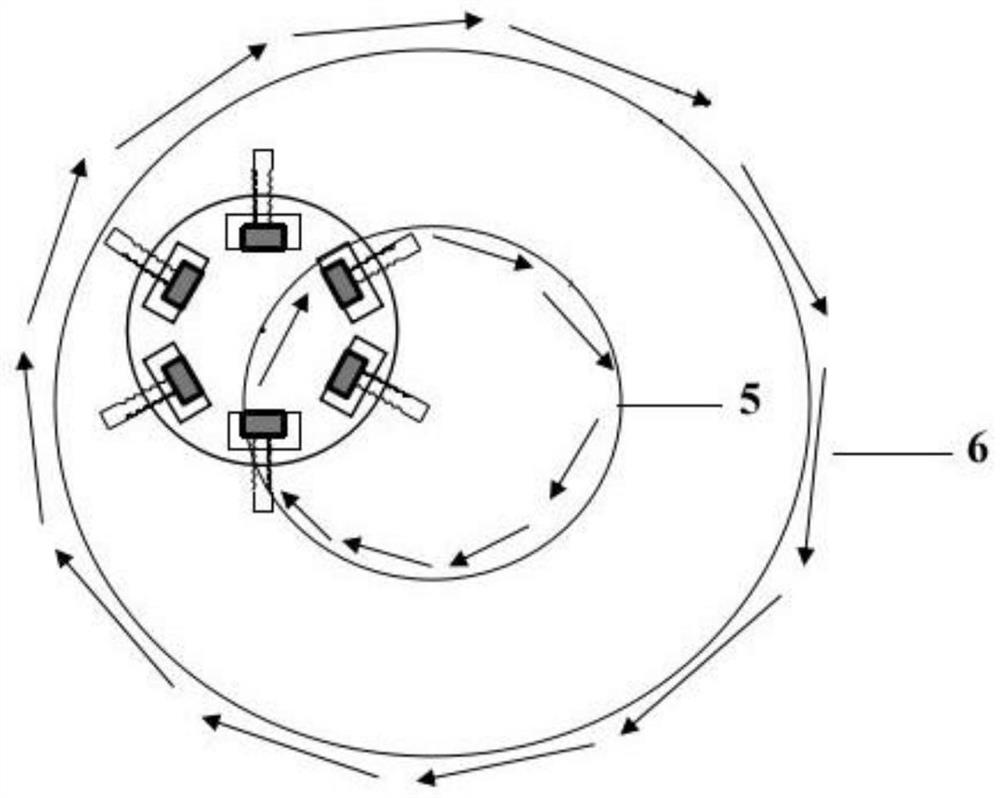

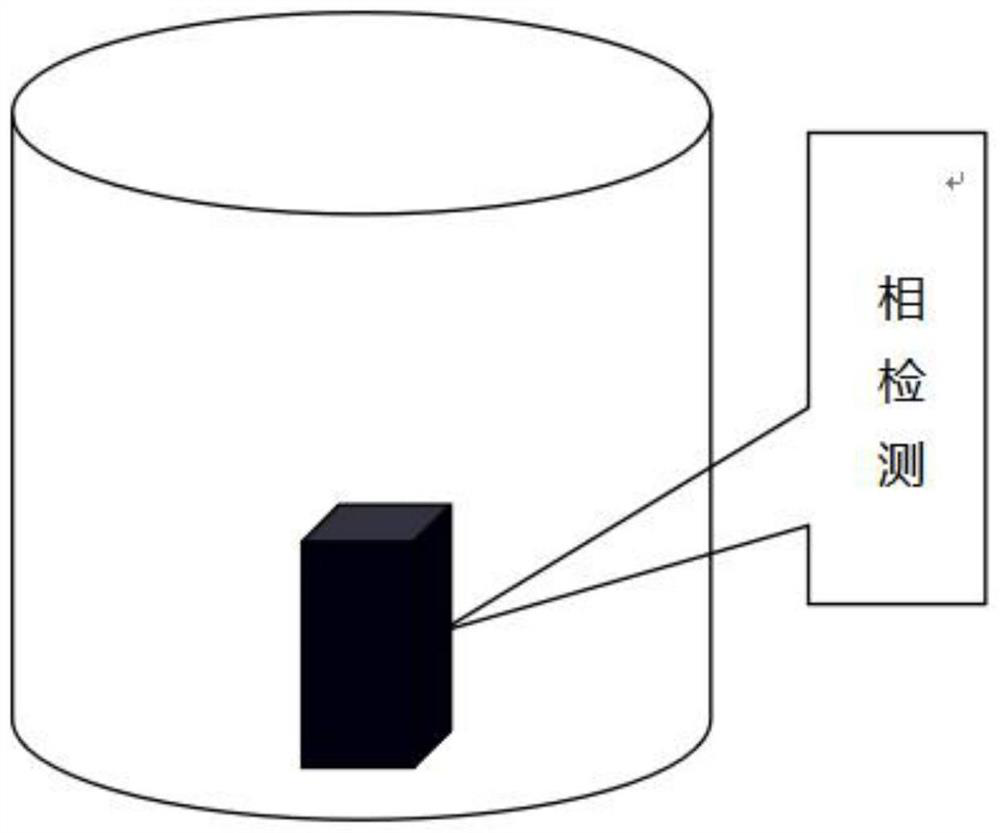

[0065] Step 2: figure 1 As shown, the cut-cutting resistance test sample 1 is fixed to the clamp seat 3 of the automatic grinding blast, and the mortal solid position 4 is fixed, and see it. figure 1 . The surface to be tested for the test sample 1 is facing down and is as close as possible to the horizontal position. Since the polishing machine clamp holder is mostly circular, it is necessary to pay attention to the load-bearing dramatically 1 symmetry to maintain the loaded drain sample 1. Waiting to die on the automatic grinding machine clip hold position 4 figure 1 Indicated. The automatic polishing machine is coarse, fine grinding, rough thread, and the grinding diameter used in the refined process is 300mm, and the d...

Embodiment 2

[0079] The same technical parameters and steps as Example 1 were used to prepare a GH2132 high-temperature all-in-gold gold phase. Figure 5 It is a carbide morphology of the gold phase sample prepared in this embodiment. As can be seen from the figure, the carboned carbon of the gold phase sample prepared by the technical solution using the present embodiment is clearly visible, and there is no pollutant near the carbide, and there is no anti-crushing condition, and the gold phase automatic detection requirements can be met. .

Embodiment 3

[0081] The same technical parameters and steps as Example 1 were used to prepare GH3625 high-temperature co-gold group samples. Figure 6 It is a carbide morphology of the gold phase sample prepared in this embodiment. As can be seen from the figure, the carboned carbon of the gold phase sample prepared by the technical solution using the present embodiment is clearly visible, and there is no pollutant near the carbide, and there is no anti-crushing condition, and the gold phase automatic detection requirements can be met. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com