Method for regulating and controlling stability of aluminum alloy by combining surface treatment with subsequent heat treatment

A follow-up heat treatment and surface treatment technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the deterioration of thermal stability of 2A12 aluminum alloy material, the long-term use of navigation inertial instruments, and reduce the accuracy of aircraft and service life, to achieve the effect of good interface bonding, promotion of thermal stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) The cold-rolled 2A12 aluminum alloy was mechanically polished for 1 min, and then cleaned in absolute ethanol solution for 3 min; then, the cleaned 2A12 aluminum alloy was placed in a PdCl 2 In the activation solution composed of hydrochloric acid, ultrasonic activation treatment was performed for 7 minutes, and then placed in absolute ethanol solution for ultrasonic cleaning for 4 minutes.

[0039] (2) Put the cleaned aluminum alloy in the activation solution for ultrasonic activation treatment. The amount of each component contained in each liter of activation solution is: PdCl 2 is 1g / L; hydrochloric acid is 25mL / L, and the mass percent concentration of hydrochloric acid is 20%.

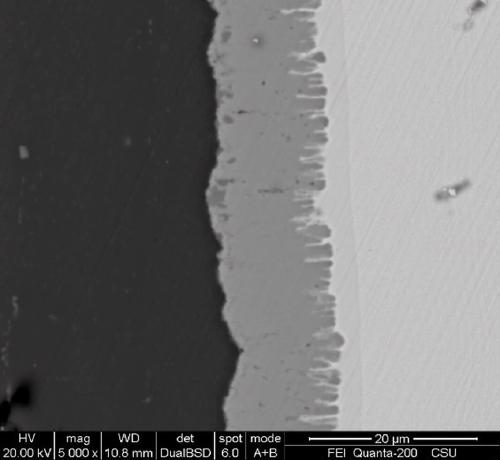

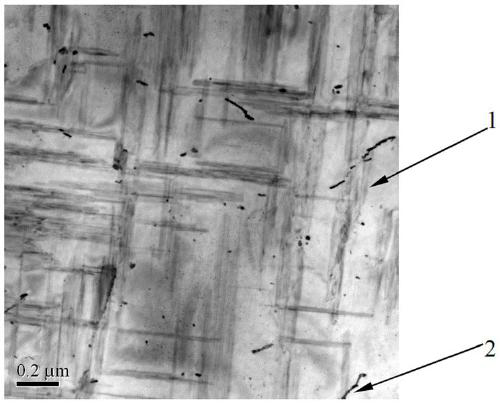

[0040] (3) Place the activated aluminum alloy in the plating solution for ultrasonic electroless plating. The electroless plating requires 0.8L of plating solution per kilogram of 2A12 aluminum alloy. Add 2A12 aluminum alloy to the plating solution. Under the temperature, carry out ult...

Embodiment 2

[0046] (1) The cold-rolled 2A12 aluminum alloy was mechanically polished for 2 minutes, and then cleaned in absolute ethanol solution for 4 minutes; then, the cleaned 2A12 aluminum alloy was placed in a PdCl 2 In the activation solution composed of hydrochloric acid, ultrasonic activation treatment was performed for 10 minutes, and then placed in absolute ethanol solution for ultrasonic cleaning for 5 minutes.

[0047] (2) Put the cleaned aluminum alloy in the activation solution for ultrasonic activation treatment. The amount of each component contained in each liter of activation solution is: PdCl 2 is 1.25g / L; hydrochloric acid is 30mL / L, and the mass percent concentration of hydrochloric acid is 10%.

[0048] (3) Put the activated aluminum alloy in the plating solution for ultrasonic chemical plating. The electroless plating requires 1L of plating solution per kilogram of 2A12 aluminum alloy. Add 2A12 aluminum alloy to the plating solution at a temperature of 80°C. Under,...

Embodiment 3

[0054] (1) The cold-rolled 2A12 aluminum alloy was mechanically polished for 3 minutes, and then cleaned in absolute ethanol solution for 5 minutes; then, the cleaned 2A12 aluminum alloy was placed in a PdCl 2 In the activation solution composed of hydrochloric acid, ultrasonic activation treatment was performed for 5 minutes, and then placed in absolute ethanol solution for ultrasonic cleaning for 3 minutes.

[0055] (2) Put the cleaned aluminum alloy in the activation solution for ultrasonic activation treatment. The amount of each component contained in each liter of activation solution is: PdCl 2 is 1.5g / L; hydrochloric acid is 35mL / L, and the mass percent concentration of hydrochloric acid is 30%.

[0056] (3) Put the activated aluminum alloy in the plating solution for ultrasonic chemical plating. The electroless plating requires 1.2L of plating solution per kilogram of 2A12 aluminum alloy. Add 2A12 aluminum alloy to the plating solution. Under the temperature, carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com