Design method of heat exchange-resistance type slit cold end heat exchanger for composite refrigerating machine

A cold-end heat exchanger and composite refrigeration technology, which is applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problem of volume and weight unfavorable for the space application of the composite refrigerator in the extremely low temperature area, and unfavorable for the composite refrigerator in the extremely low temperature area. performance, resistance and pressure drop, etc., to achieve the effect of efficient heat exchange, increase heat exchange, and reduce flow piezoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

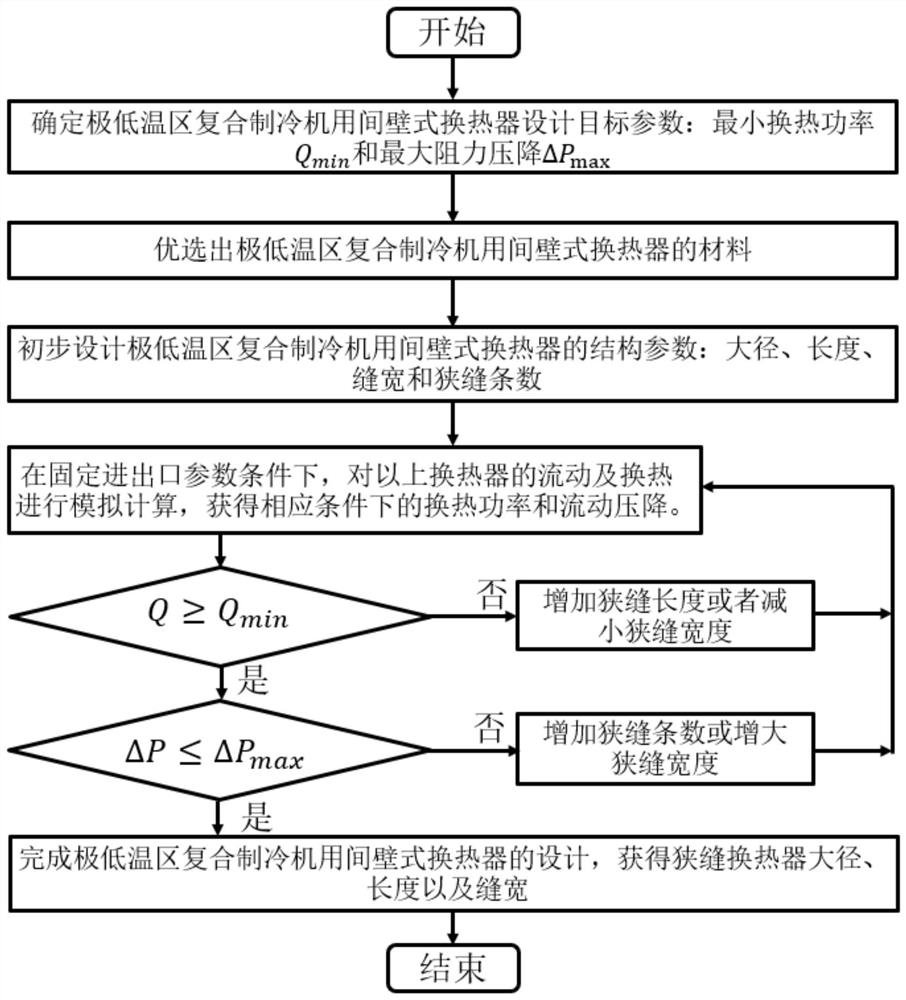

[0027] figure 1 It is a flow chart of the design method of a heat transfer-resistance type slit cold end heat exchanger invented for a composite refrigerator in the extremely low temperature region.

[0028] A heat transfer-resistance type slit cold-end heat exchanger design method for composite refrigerators in extremely low temperature regions, characterized in that it includes the following steps:

[0029] Step 1: According to the actual project, determine the design target parameters of the heat transfer-resistance type slit cold end heat exchanger for the composite refrigerator in the extremely low temperature zone: the minimum heat transfer Q min and the maximum resistance pressure drop ΔP max .

[0030] Step 2: According to the actual working conditions, select the material of the heat transfer-resistance slit cold en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap