Simulation teaching device and system of antioxidant production device

A technology for production equipment and teaching equipment, applied in teaching models, educational appliances, instruments, etc., can solve the problems of limited training and practice of production equipment, inability to complete the technological process, and lack of chemical production equipment, etc., to cultivate teamwork ability and convenience. The effect of training management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

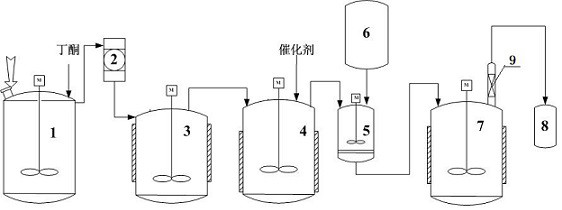

[0050] In this embodiment, the "software version" is taken as an example, and the simulation operation training is carried out on the whole antioxidant production process, which is divided into three sections: dissolution, reaction and rectification. The dissolution section is p-phenylenediamine and methyl ethyl ketone The preparation of the reaction section is the reductive alkylation of p-phenylenediamine; the rectification section is the purification of antioxidant products.

[0051] The simulation operation training for the above-mentioned positions is to simulate the actual chemical production process in real time through the simulation flow chart picture on the computer, with the help of the computing power of the computer, and replace the actual chemical production device with a mathematical model. Trainees can independently complete the training operations of cold driving, normal parking and accident handling on the computer; including the simulation of cold driving, no...

Embodiment 2

[0066] The "practical version" uses the entire antioxidant production process to carry out simulated production operation training, which is divided into three sections: dissolution, reaction and distillation. The dissolution section is the preparation of p-phenylenediamine and methyl ethyl ketone, the reaction The working section is the reductive alkylation reaction of p-phenylenediamine; the rectifying working section is the purification of antioxidant products.

[0067] The simulated production operation training for each post mentioned above is connected with the DCS system through OPC interface technology to realize data communication between the central control room and the site. Operate the opening and stopping of manual valves and various moving equipment at the real production site, but cannot control the automatic control valves; the opening status of all valves and the specific values of each parameter are displayed on the control interface of the computer DCS soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com