Solar cell and preparation method thereof

A technology for solar cells and battery materials, applied in the field of solar cells, can solve the problems of insufficient power-to-weight ratio, easy-split yield, etc., and achieve the effects of reducing the preparation cost, reducing the risk of splitting, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

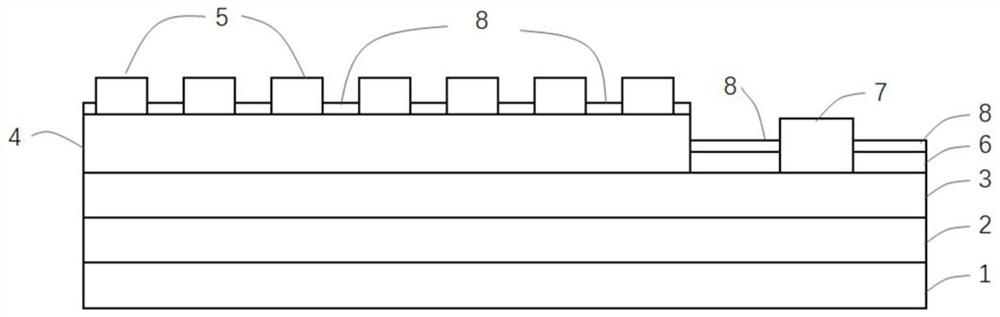

[0100] This embodiment prepares a kind of solar cell, specifically comprises the following steps:

[0101] S1. Epitaxially growing a sacrificial layer on the first substrate, the material of the sacrificial layer is AlAs, and the thickness is 10 nm;

[0102] S2. On the surface of the sacrificial layer far away from the first substrate, a battery material layer 4 is arranged. The battery material layer 4 includes an n-GaAs layer, a GaInP battery layer, a tunnel junction, and a GaAs battery layer that are epitaxially grown in sequence starting from the surface of the sacrificial layer. , GaInP cut-off layer and p-GaAs layer;

[0103] S3. On the surface of the battery material layer 4 away from the first substrate, electron beam evaporation is used to arrange a back metal layer 3 with a total thickness of 3um. The back metal layer 3 is a composite layer formed by a Ni layer and an Au layer, wherein Ni Thickness 1um, Au thickness 2um;

[0104] S4. On the surface of the back meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com