A method of using a casing waterproof led lamp belt glue filling packaging device

A technology for LED light strips and packaging devices, which is applied in the direction of air-proof/waterproof devices, separation methods, lighting devices, etc., which can solve the problems of cracking LED light strips, low work efficiency, and high production costs, and reduce cracking or failure. Waterproof, improve work efficiency and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Such as figure 1 , 2 , 3, 4, 5, 6, and 10, a method for using a casing waterproof LED strip 8 glue-filling packaging device,

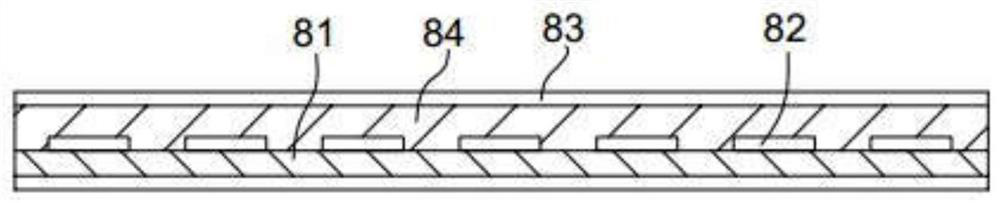

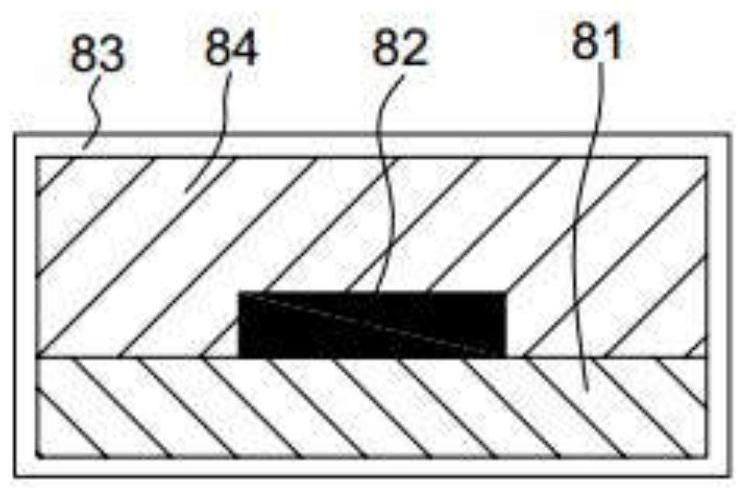

[0054] Such as figure 1 , 2 As shown, the LED light strip 8 includes a flexible circuit board, several LEDs 82 arranged on the circuit board, and a flexible sleeve 83 wrapped on the flexible circuit board; the flexible circuit board includes several flexible circuit board units; the flexible sleeve 83 The cross section of the through hole 41 is also rectangular.

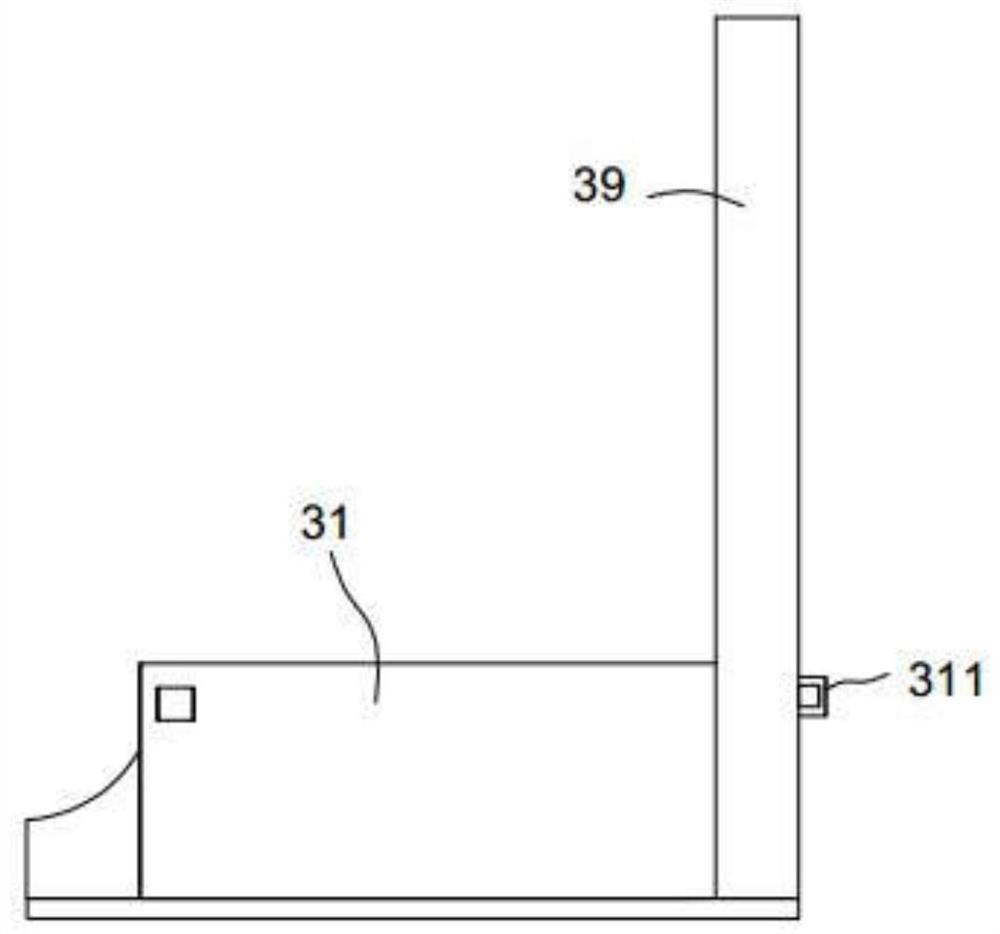

[0055] The packaging device includes an operation unit 3, a glue filling structure 1 and a controller 2;

[0056] The operation unit 3 includes a wiring table 31 for arranging several LED light strips 8, a receiving device for positioning and clamping the ends of several LED light strips 8, and a pouring device cooperating with the receiving device; 8 and mutually parallel wiring grooves 32, on both sides of the wiring groove 32, there are rollers 33 that drive the LED light strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com