Hydrogen-oxygen fuel cell pole plate and manufacturing method thereof

A fuel cell plate and manufacturing method technology, which is applied to fuel cells, circuits, electrical components, etc., can solve problems such as difficulty in ensuring sealing and encapsulation effects, complex fabrication of metal flow field plates, and complex sealing process of electrode plates, etc., to achieve enhanced anti-corrosion Cross-leakage performance, shortened production cycle, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

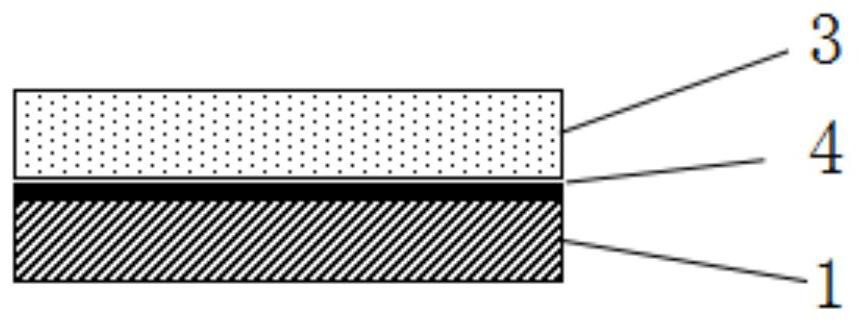

[0040] Such as Figure 6 As shown, this embodiment proposes a hydrogen-oxygen fuel cell plate, including a cathode plate and an anode plate that are bonded to each other, wherein the anode plate includes a hydrogen flow field plate 1, a water flow field plate 2 and a gas barrier conductive film 4, The cathode plate includes an air-oxygen flow field plate 3, a water flow field plate 2 and a gas-barrier conductive film 4, and the hydrogen flow field plate 1, the air-oxygen flow field plate 3 and the water flow field plate 2 are plates made of a mixture of graphite and resin The hydrogen flow field plate 1, the air oxygen flow field plate 3 and the water flow field plate 2 all have a plane surface on one side, and a flow field on the other side surface, and the plane side of the hydrogen flow field plate 1 and the water flow field The plane side of the plate 2 is attached to both sides of a gas barrier conductive film 4 to form an anode plate, and the plane side of the air oxygen...

Embodiment 2

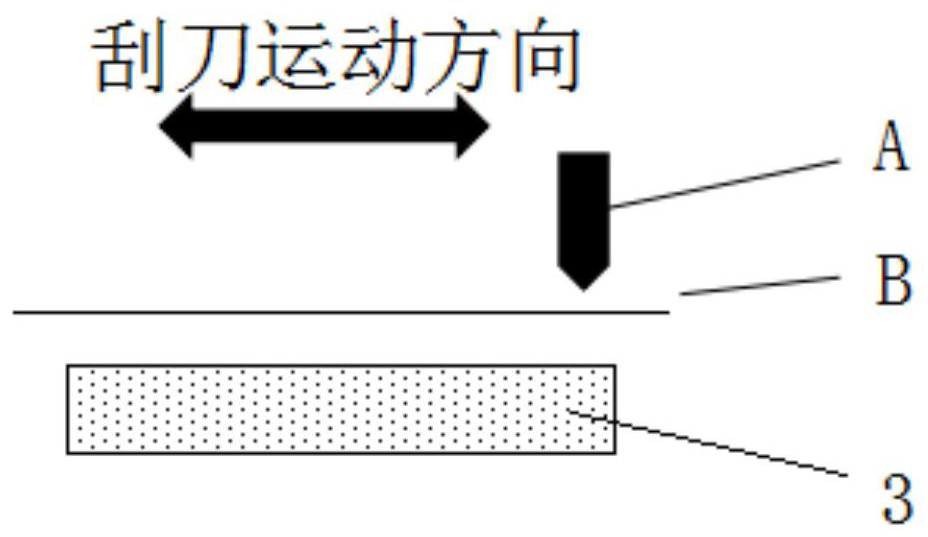

[0044] Such as Figure 1-Figure 7 As shown, this embodiment proposes a method for manufacturing a hydrogen-oxygen fuel cell plate, and making the hydrogen-oxygen fuel cell plate in Example 1 includes the following steps:

[0045] Step 1. Make cathode plate and cathode plate:

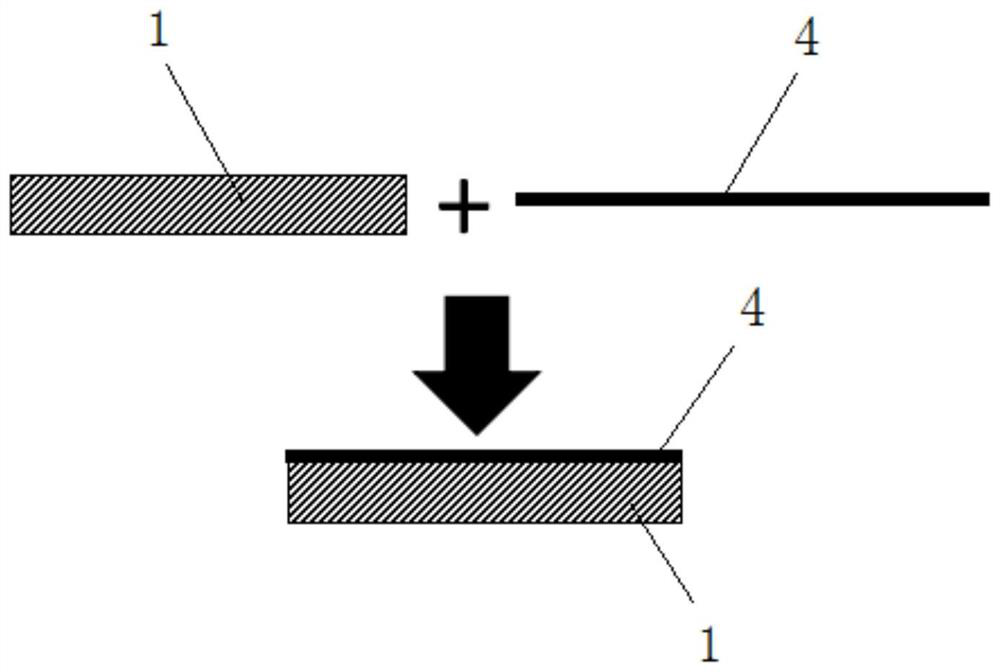

[0046] Make the anode plate: Prepare the gas-barrier conductive film 4, attach the first side of the gas-barrier conductive film 4 to the plane side of one of the hydrogen flow field plate 1 or the water flow field plate 2; attach the hydrogen flow field plate 1 or the water flow field plate The other plane side of the field plate 2 is attached to the second side of the gas barrier conductive film 4;

[0047] Make the cathode plate: prepare the gas-barrier conductive film 4, attach the first side of the gas-barrier conductive film 4 to the plane side of one of the air-oxygen flow field plate 3 or the water flow field plate 2; place the air-oxygen flow field plate 3 or The other plane side of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com