Automatic assembling equipment for rotor iron core magnetic shoes

A technology of rotor core and automatic assembly, applied in the manufacture of stator/rotor body, electric components, electric vehicles, etc., can solve the problems of low degree of automation, low work efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

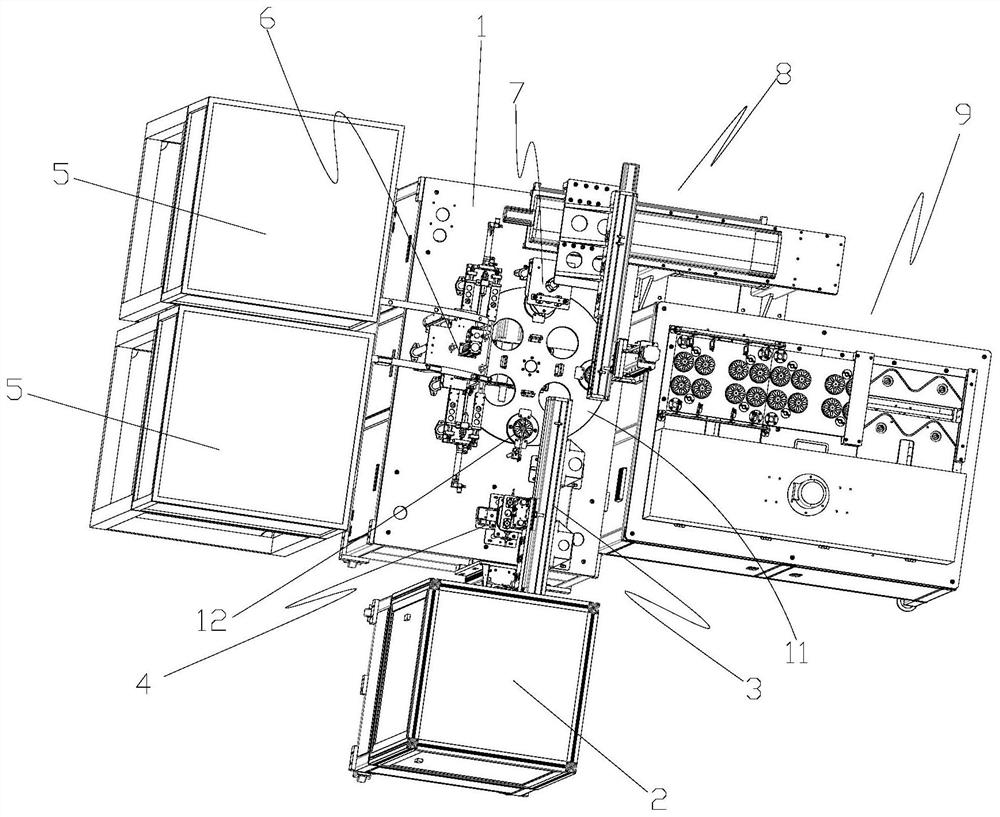

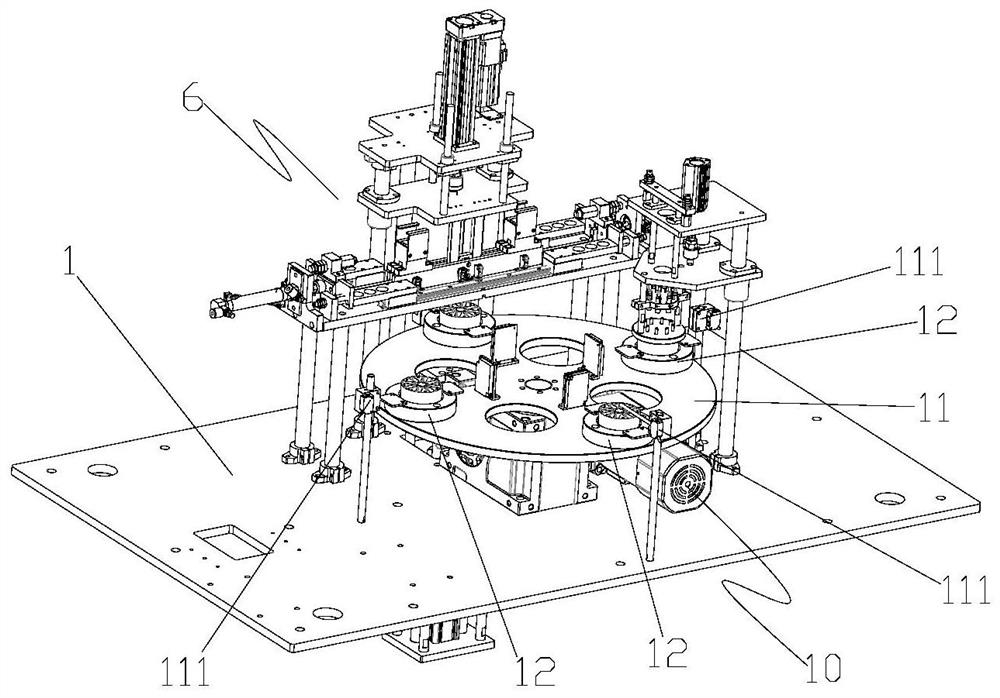

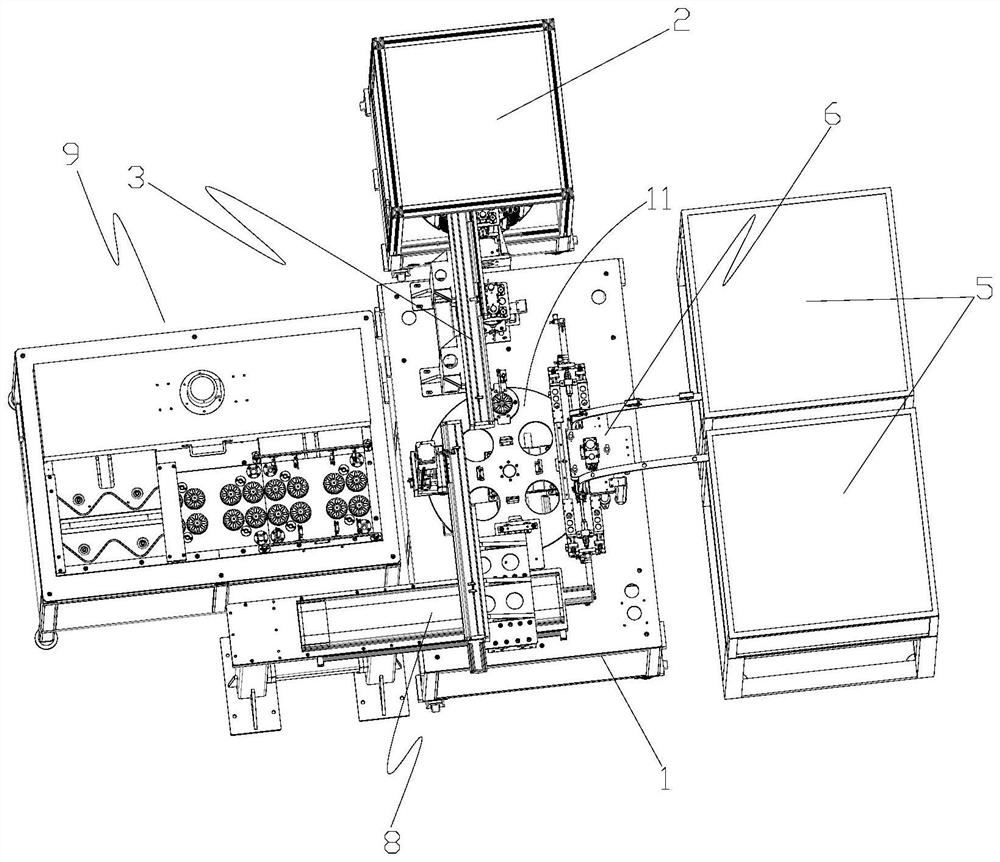

[0043] Attached below Figure 1-20 Embodiments of the present invention will be described in detail.

[0044] like Figure 1-20 As shown, a rotor core magnetic tile automatic assembly equipment of the present invention includes a frame 1, and the frame 1 is provided with a clamping jig 12 that can move relative to the frame 1 and can clamp the rotor core 100, The frame 1 is provided with a rotor core storage device 2 capable of storing the rotor core 100, and the frame 1 is provided with a rotor core 100 capable of transporting the rotor core storage device 2 to the clamping The rotor core handling device 3 clamped on the jig 12, the frame 1 is provided with a magnetic tile supply device 5 capable of storing and transporting the magnetic tile 200, and the frame 1 is provided with a magnetic tile supply device capable of receiving 5 and assemble the magnetic tile 200 to the corresponding assembly groove 110 of the rotor core 100. The frame 1 is provided with a A detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com